A kind of high nickel ternary lithium ion battery positive electrode material and preparation method thereof

A lithium-ion battery and cathode material technology, applied in the field of high-nickel ternary lithium-ion battery cathode materials and its preparation, can solve the problems of high-nickel ternary materials such as poor cycle performance, reduced operating voltage, and poor rate performance, and achieve improved Effects of electrochemical kinetic performance, enhanced stability, and improved rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh reactants such as 0.01mol lithium chloride, 0.009mol nickel nitrate, 0.0005mol cobalt nitrate, 0.0005mol scandium nitrate and 0.02mol citric acid, put them all into a 200mL beaker, add 100mL distilled water, and then add The beaker was moved to a water bath at 80°C, and the reaction was performed with stirring until a gel formed.

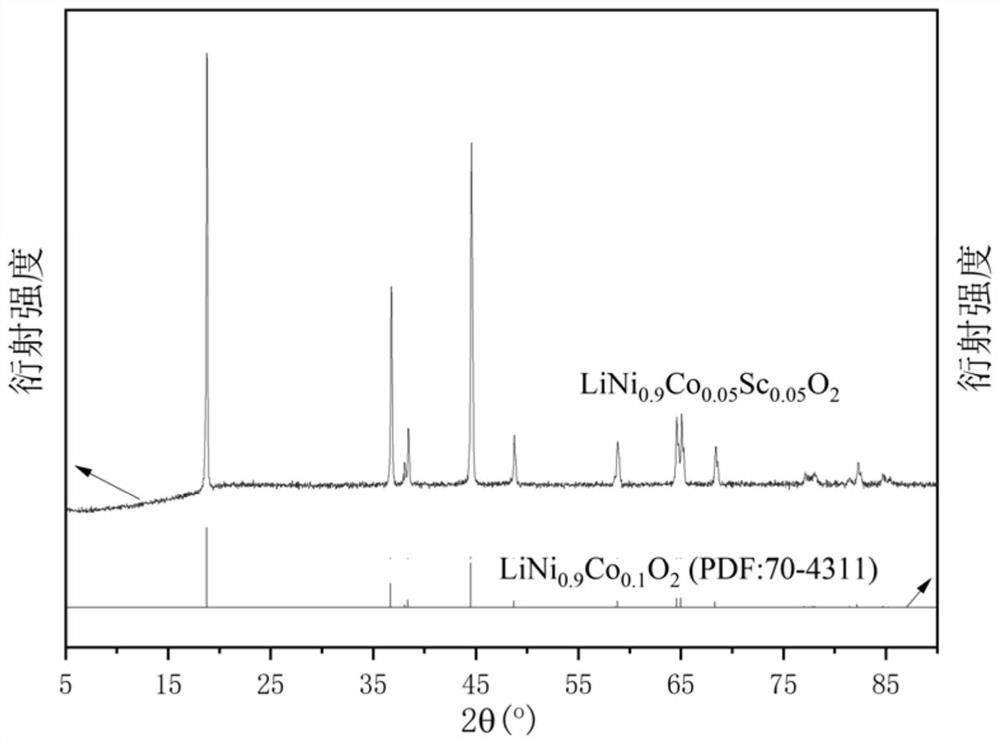

[0023] (2) drying the gel obtained in step (1), then transferring the dried gel to a muffle furnace, heating to 800°C at a heating rate of 5°C / min and maintaining a constant temperature for 6 hours, and then cooling naturally, Get LiNi 0.9 Co 0.05 Sc 0.05 O 2 . figure 1 is the X-ray diffraction pattern of the material.

[0024] The prepared lithium ion battery cathode material LiNi 0.9 Co 0.05 Sc 0.05 O 2 , acetylene black and PVDF are ground and mixed evenly at a mass ratio of 8:1:1, drop an appropriate amount of NMP to make electrode slurry, and then coat and grind the slurry evenly on aluminum foil, and place it in a vac...

Embodiment 2

[0026] (1) Weigh reactants such as 0.01mol lithium nitrate, 0.0087mol nickel nitrate, 0.0005mol cobalt nitrate, 0.0008mol scandium nitrate and 0.02mol tartaric acid, put them all into a 200mL beaker, add 100mL distilled water, and then transfer the beaker In a water bath at 80°C, react with stirring until a gel forms.

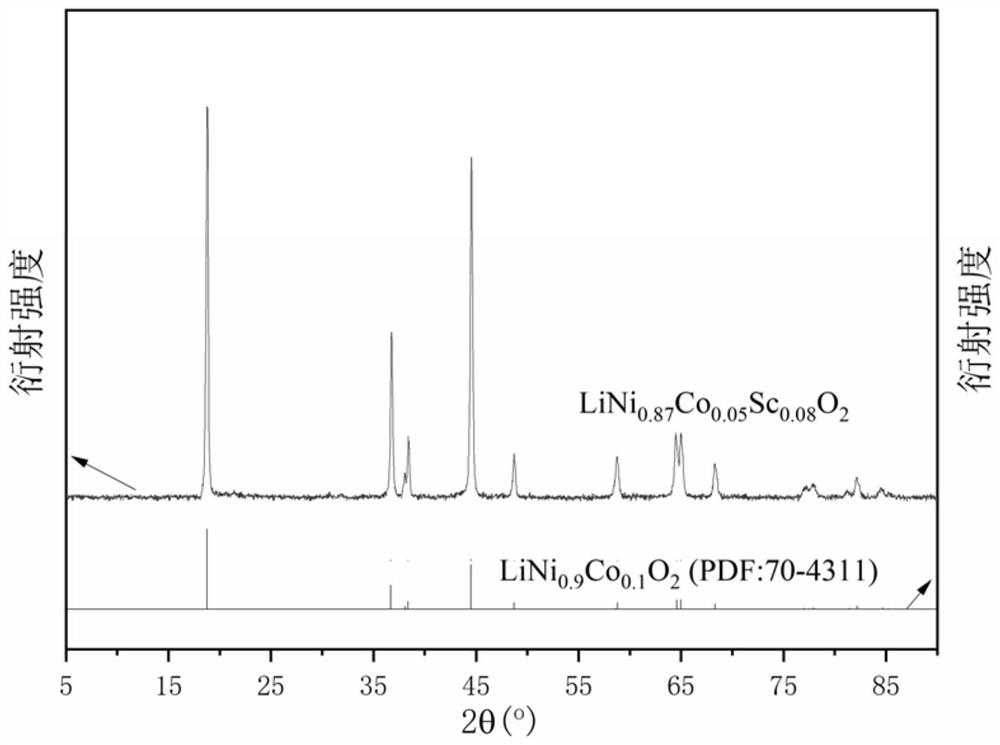

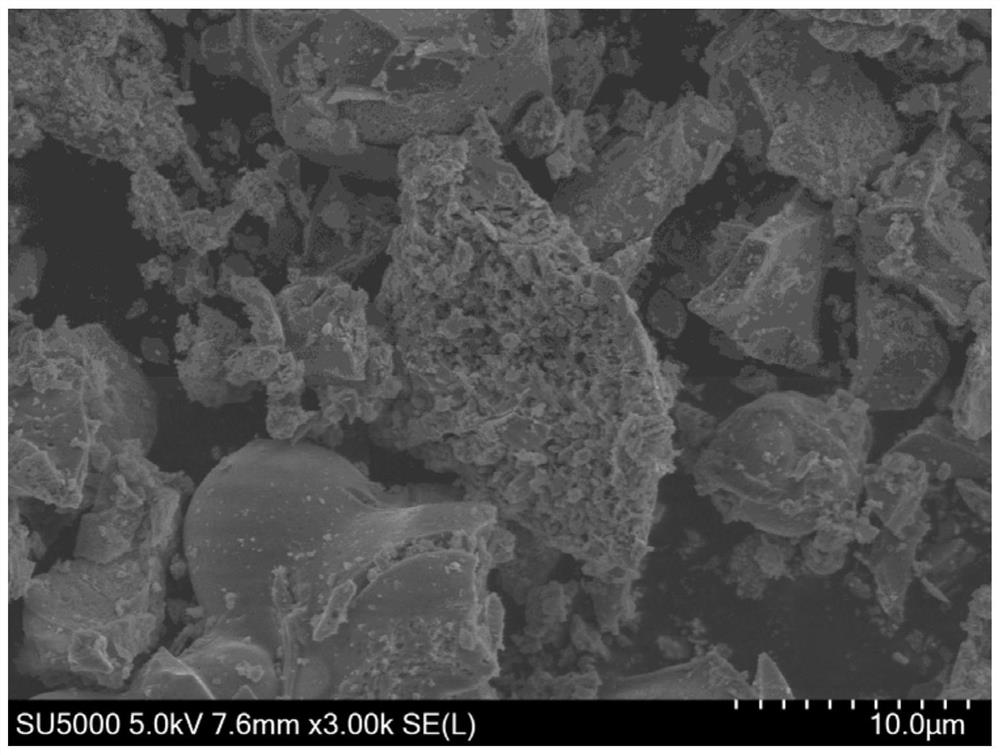

[0027] (2) drying the gel obtained in step (1), then transferring the dried gel to a muffle furnace, heating to 800°C at a heating rate of 5°C / min and maintaining a constant temperature for 6 hours, and then cooling naturally, Get LiNi 0.87 Co 0.05 Sc 0.08 O 2 . figure 2 is the X-ray diffraction pattern of the material. image 3 SEM image of the material.

[0028] The prepared lithium ion battery cathode material LiNi 0.87 Co 0.05 Sc 0.08 O 2 , acetylene black and PVDF are ground and mixed evenly at a mass ratio of 8:1:1, drop an appropriate amount of NMP to make electrode slurry, and then coat and grind the slurry evenly on aluminum foil, and place ...

Embodiment 3

[0030] (1) Weigh reactants such as 0.015mol lithium chloride, 0.01275mol nickel chloride, 0.0015mol cobalt nitrate and 0.00075mol scandium nitrate and 0.03mol citric acid, put them all into a 200mL beaker, add 120mL distilled water, then Move the beaker to a water bath at 80°C and react with stirring until a gel forms.

[0031] (2) drying the gel obtained in step (1), then transferring the dried gel to a muffle furnace, heating to 800°C at a heating rate of 5°C / min and maintaining a constant temperature for 6 hours, and then cooling naturally, Get LiNi 0.85 Co 0.1 Sc 0.05 O 2 .

[0032] The prepared lithium ion battery cathode material LiNi 0.85 Co 0.1 Sc 0.05 O 2 , acetylene black and PVDF are ground and mixed evenly at a mass ratio of 8:1:1, drop an appropriate amount of NMP to make electrode slurry, and then coat and grind the slurry evenly on aluminum foil, and place it in a vacuum drying oven at 120 °C. It was fully dried in the middle and cut into a foil with a di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com