Vacuum insulated panel cast-in-place concrete system for buildings

A technology of vacuum insulation panels and concrete, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of long construction period, low weather resistance period, pulverization and peeling, etc., and achieve long weather resistance period, long service life and not easy cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

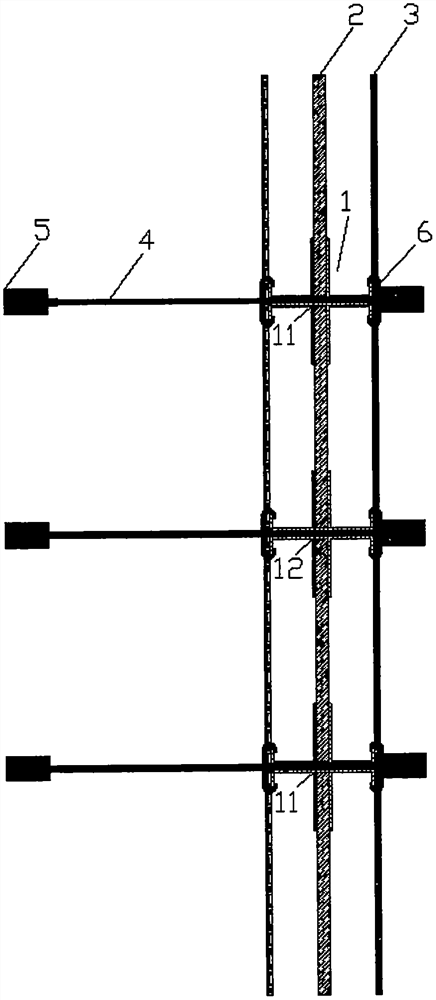

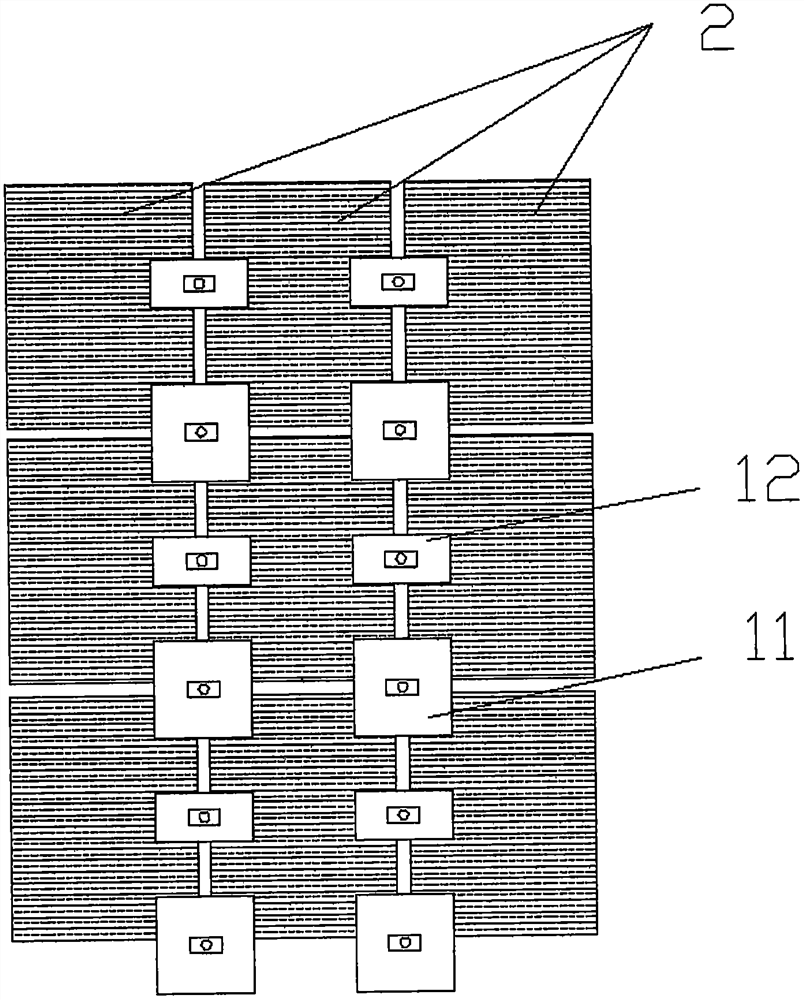

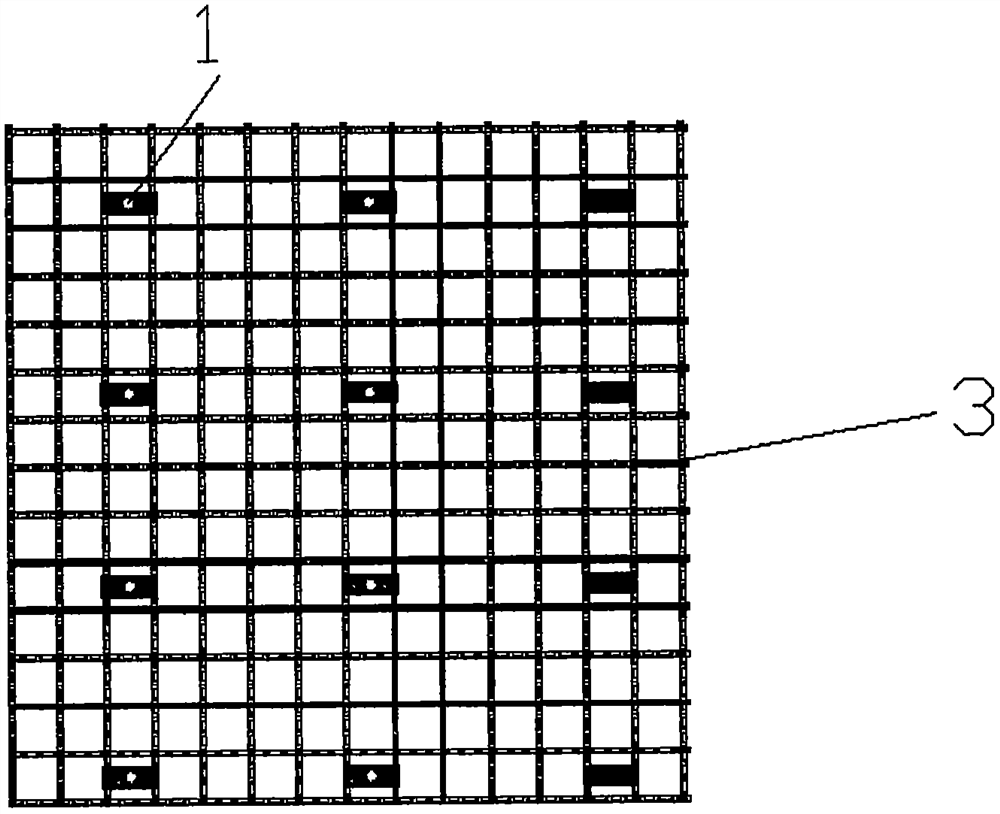

[0024] Please refer to the accompanying drawings. In an embodiment of the present invention, a vacuum insulation panel cast-in-situ concrete system for construction includes a chuck 1. A vacuum insulation panel 2 is clamped inside the chuck 1. The two sides of the chuck 1 are Steel wire mesh sheets 3 are all provided, the middle part of the chuck 1 is provided with galvanized round steel 4 , and fixed caps 5 are provided at both ends of the galvanized round steel 4 .

[0025] In the present invention, the chuck 1 and the steel wire mesh 3 are connected through the steel buckle 6 provided, and the middle part of the chuck 1 and the steel buckle 6 is provided with a through hole 7 for the galvanized round steel 4 to pass through.

[0026] In the present invention, both ends of the galvanized round steel 4 are provided with external threads 41 , and one end of the fixing cap 5 is provided with internal threads 51 engaged with the external threads 41 .

[0027] In the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com