A cold-rolled steel plate for enamel and its manufacturing method

A technology of cold-rolled steel plate and enamel, which is applied in the field of metal materials and its manufacturing, can solve the problems such as difficulty in ensuring the carbon content of finished products, and achieve the effects of improving the surface quality of enamel, improving efficiency, and preventing pinhole defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

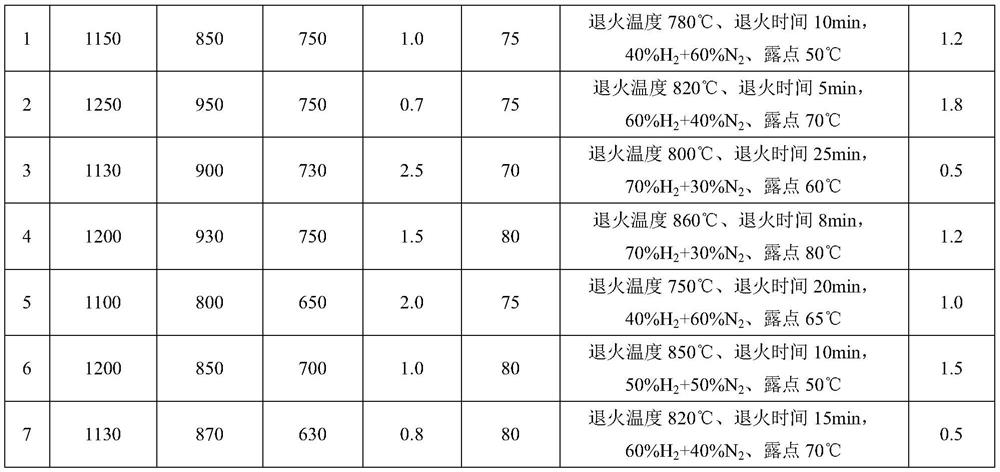

[0099] The cold-rolled steel sheet for enamel of the present invention adopts the following steps to obtain:

[0100] (1) Preparation of slab: molten iron is cast into slab after converter smelting and refining, wherein the carbon content in molten steel after refining is ≤0.04%;

[0101] (2) Hot rolling: control the heating temperature during hot rolling to be 1100 to 1250 °C, the final rolling temperature to be 800 to 950 °C, and then cool to a coiling temperature of 600 to 750 °C;

[0102] (3) Pickling;

[0103] (4) Cold rolling: control the total reduction ratio of cold rolling ≥ 65%;

[0104] (5) Degreasing;

[0105] (6) Decarburization annealing: the annealing temperature is 750~900℃, the annealing time is 30s~30min, the atmosphere in the annealing furnace includes hydrogen and nitrogen, the hydrogen content is 20~80%, and the dew point is 50~80℃;

[0106] (7) Flattening: control the flattening reduction rate ≤5%.

[0107] Table 1 lists the mass percentage ratio of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com