A kind of anticorrosion, flame retardant formaldehyde-free plywood and preparation method thereof

A kind of plywood and flame-retardant technology, which is applied in the direction of chemical instruments and methods, adhesives, adhesive types, etc., can solve the problems of formaldehyde generation and insufficient strength of plywood, and achieve reduced formaldehyde release, superior stability, and thickening properties and good effect of thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

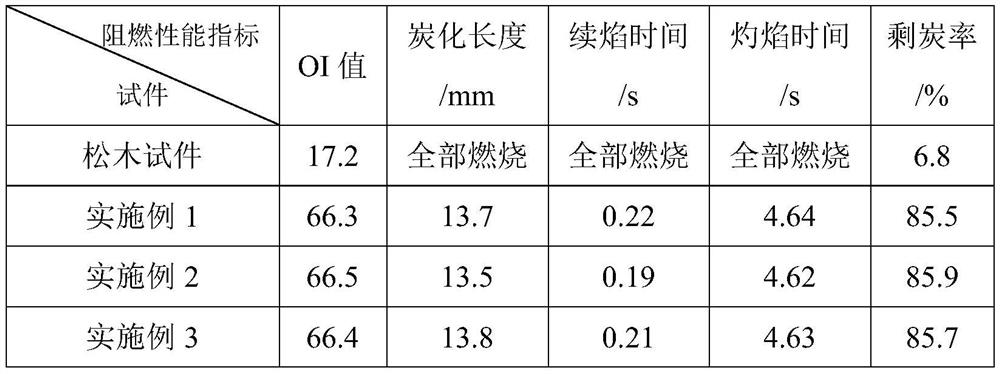

Examples

Embodiment 1

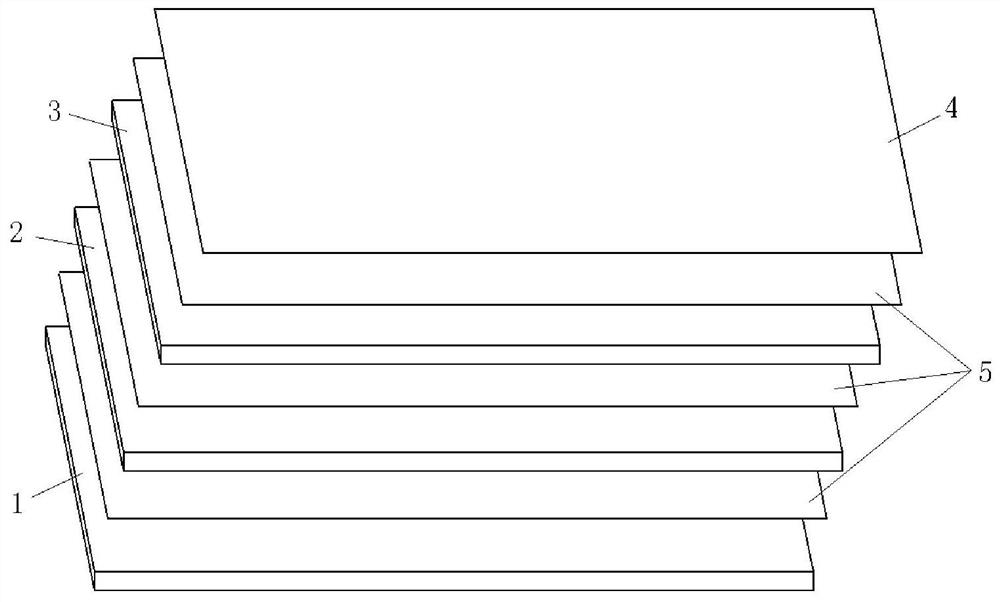

[0036]An anti-corrosion and flame-retardant formaldehyde-free plywood, comprising a first rotary-cut veneer 1, a second rotary-cut veneer 2, a third rotary-cut veneer 3, and a flame-retardant aluminum foil layer 4. The first rotary-cut veneer The plate 4 is located at the bottom, the lower surface of the second rotary cutting veneer 5 is fixedly connected with the upper surface of the first rotary cutting veneer 1 through the hot melt adhesive film 5, and the lower surface of the third rotary cutting veneer 3 is fixedly connected. The surface is fixedly connected to the upper surface of the second rotary-cut veneer 2 through the hot-melt adhesive film 5, and the lower surface of the flame-retardant aluminum foil layer 4 is fixed to the upper surface of the third rotary-cut veneer 3 through the hot-melt adhesive film 5 connect;

[0037] The hot-melt adhesive film is prepared from the following raw materials by weight: 35 parts of EVA elastomer, 6 parts of terpene resin, 10 part...

Embodiment 2

[0049] An anti-corrosion and flame-retardant formaldehyde-free plywood, comprising a first rotary-cut veneer 1, a second rotary-cut veneer 2, a third rotary-cut veneer 3, and a flame-retardant aluminum foil layer 4. The first rotary-cut veneer The plate 4 is located at the bottom, the lower surface of the second rotary cutting veneer 5 is fixedly connected with the upper surface of the first rotary cutting veneer 1 through the hot melt adhesive film 5, and the lower surface of the third rotary cutting veneer 3 is fixedly connected. The surface is fixedly connected to the upper surface of the second rotary-cut veneer 2 through the hot-melt adhesive film 5, and the lower surface of the flame-retardant aluminum foil layer 4 is fixed to the upper surface of the third rotary-cut veneer 3 through the hot-melt adhesive film 5 connect;

[0050] The hot-melt adhesive film is prepared from the following raw materials by weight: 33 parts of EVA elastomer, 10 parts of terpene resin, 15 pa...

Embodiment 3

[0062] An anti-corrosion and flame-retardant formaldehyde-free plywood, comprising a first rotary-cut veneer 1, a second rotary-cut veneer 2, a third rotary-cut veneer 3, and a flame-retardant aluminum foil layer 4. The first rotary-cut veneer The plate 4 is located at the bottom, the lower surface of the second rotary cutting veneer 5 is fixedly connected with the upper surface of the first rotary cutting veneer 1 through the hot melt adhesive film 5, and the lower surface of the third rotary cutting veneer 3 is fixedly connected. The surface is fixedly connected to the upper surface of the second rotary-cut veneer 2 through the hot-melt adhesive film 5, and the lower surface of the flame-retardant aluminum foil layer 4 is fixed to the upper surface of the third rotary-cut veneer 3 through the hot-melt adhesive film 5 connect;

[0063] The hot-melt adhesive film is prepared from raw materials including the following parts by weight: 30 parts of EVA elastomer, 15 parts of terp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com