Preparation method of super-hydrophobic coating

A technology of super-hydrophobic coatings and mixed coatings, which is applied in coatings, anti-corrosion coatings, conductive coatings, etc., which can solve the problems of easy peeling of coatings, increased coating resistance, and decreased adhesion, and achieve corrosion resistance And the effect of high wear resistance, good static conductivity and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

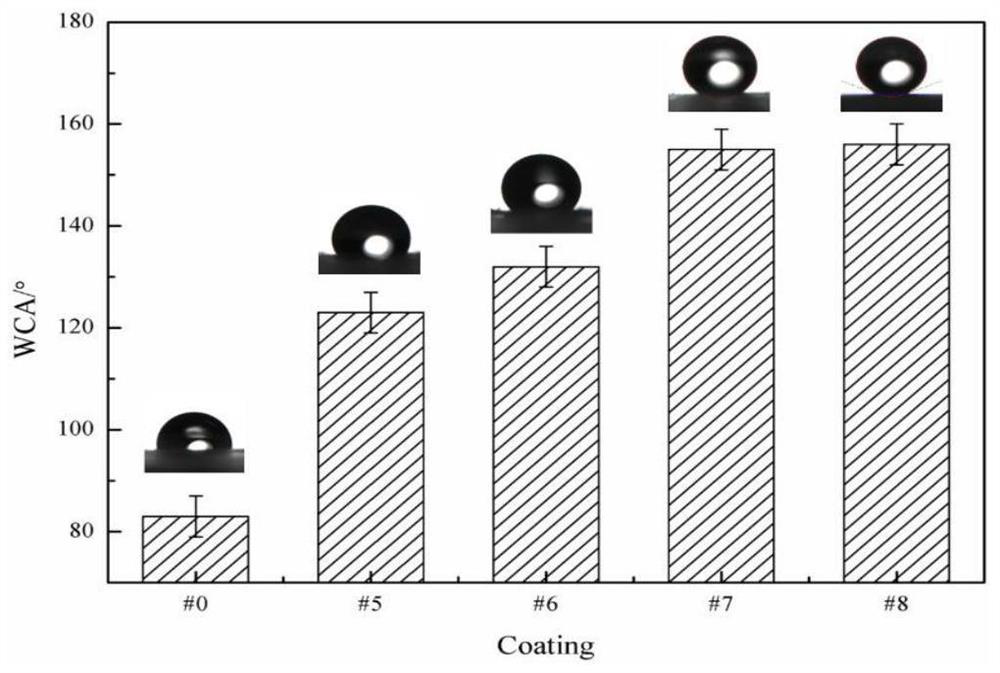

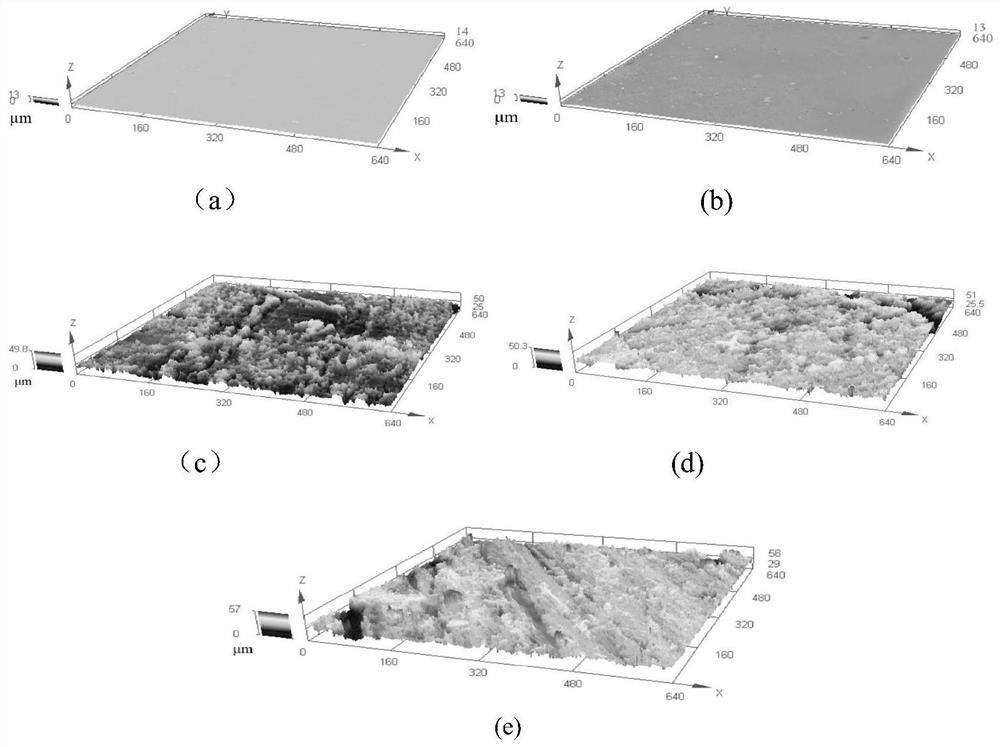

[0030] In this embodiment, in order to obtain a superhydrophobic coating with high bonding strength, which can prevent the coating from peeling, and can also meet the conductivity requirements and have superhydrophobic function when the content of the PTFE-MWCNTs hydrophobic filler system is low, The inventors conducted the following research and development.

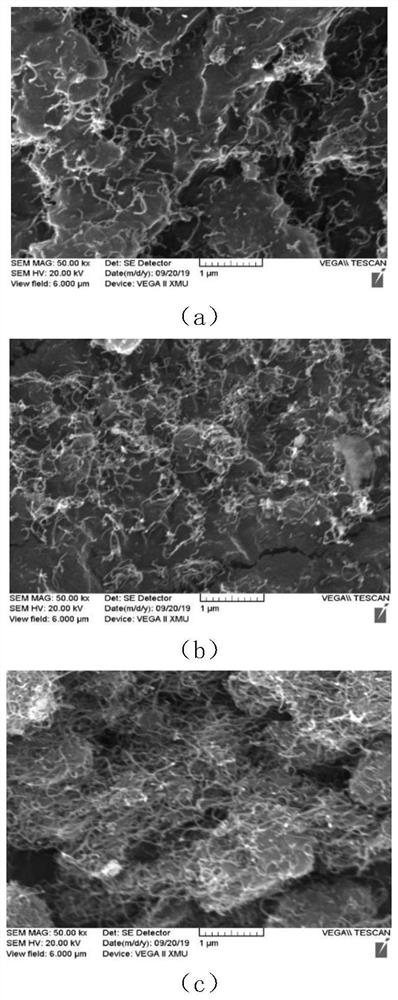

[0031] The inventors first prepared the M-MWCNTs-PTFE / WPU hybrid coating system.

[0032] At room temperature, use a magnetic stirrer to mix KH-550 silane coupling agent and distilled water at a mass ratio of 1:1 to hydrolyze the KH-550 coupling agent, store it at room temperature after hydrolysis, and store it for later use.

[0033] After that, MWCNTs particles, PTFE emulsion and hydrolyzed KH-550 silane coupling agent (the above three fillers are referred to as M-MWCNTs-PTFE hydrophobic filler system) were added to the WPU emulsion according to the dosage shown in Table 1 by magnetic stirring. A modified WPU mixed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com