Light porcelainized silicone rubber and preparation method thereof

A silicone rubber, lightweight technology, applied in the field of silicone rubber, can solve the problems of low elongation at break and tensile strength lower than 3MPa, and achieve the effects of excellent mechanical properties, simple preparation method and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

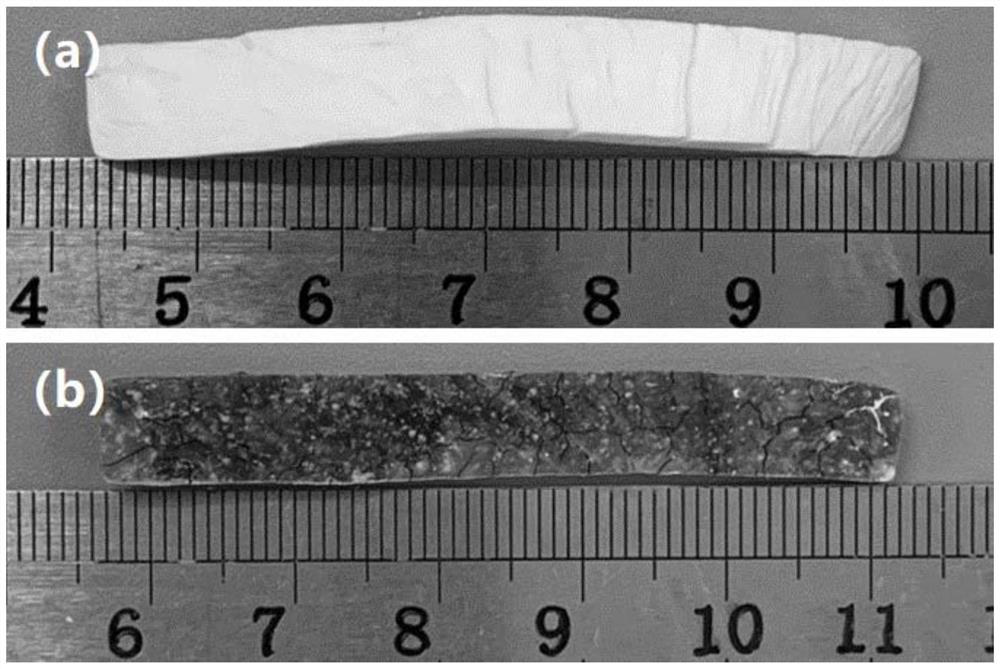

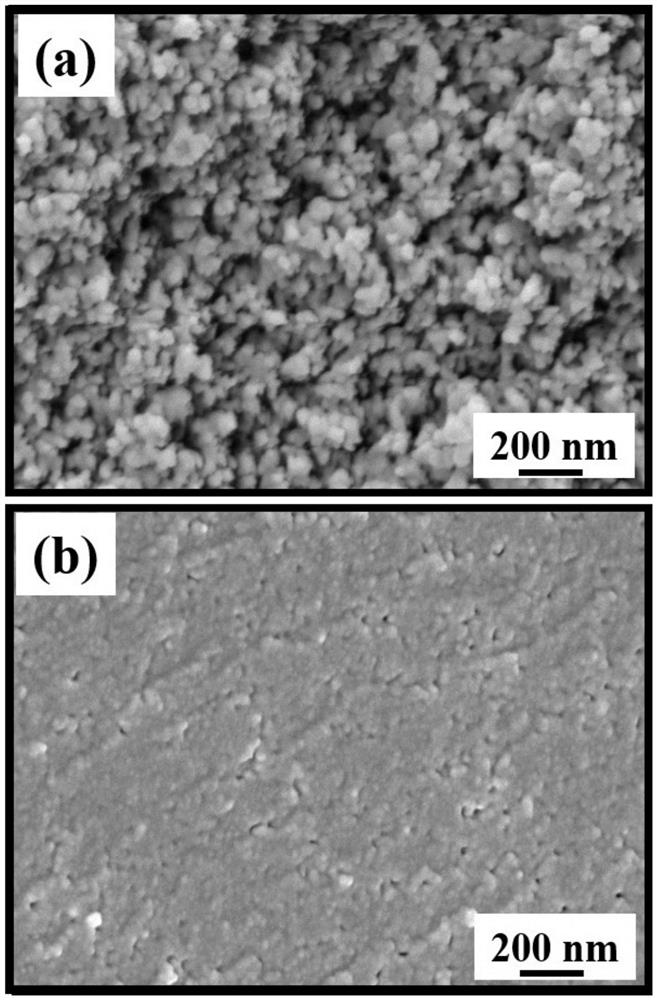

Image

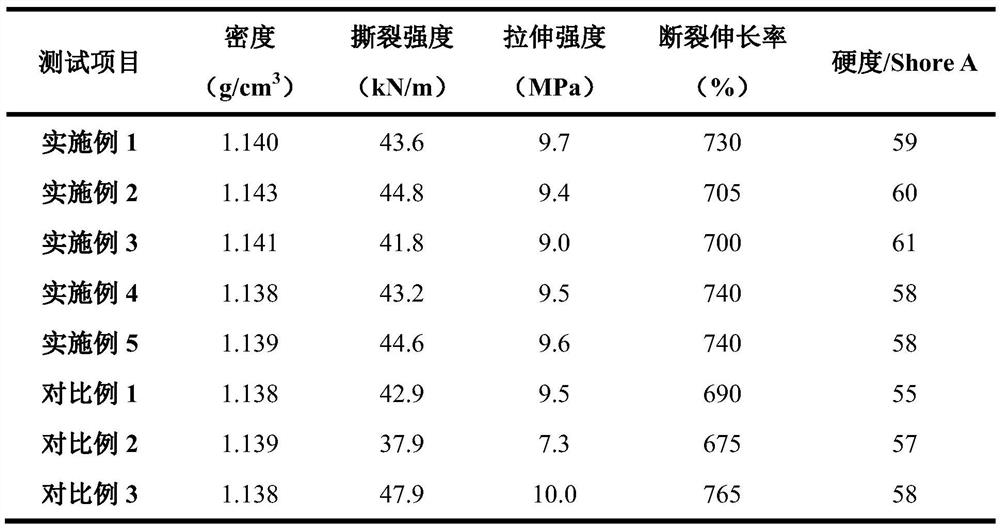

Examples

Embodiment 1

[0043] A kind of lightweight porcelainable silicone rubber, its preparation method comprises the following steps:

[0044] 1) 93 parts by mass of methyl vinyl silicone rubber with a vinyl content of 0.05 mol% (number average molecular weight 620000g / mol), 7 parts by mass of methyl vinyl silicone rubber with a vinyl content of 3.0 mol% (number average molecular weight 640000g / mol) mol), 40 mass parts specific surface area 280m 2 / g of fumed silica, 6 parts by mass of hydroxyl silicone oil with a hydroxyl content of 8.5wt%, 0.6 parts by mass of hydrogen-containing silicone oil with a hydrogen content of 1.2wt%, and 2 parts by mass of γ-piperazinylpropylmethyl dimethyl Add oxysilane to the kneader, knead for 2 hours, then raise the temperature to 150°C and knead for 3 hours, then vacuumize and knead at 120°C for 1 hour, cool to room temperature, and obtain the silicone rubber base rubber;

[0045] 2) The silicone rubber base rubber of step 1), 0.4 parts by mass of boron oxide wi...

Embodiment 2

[0048] A kind of lightweight porcelainable silicone rubber, its preparation method comprises the following steps:

[0049]1) 98 parts by mass of methyl vinyl silicone rubber with a vinyl content of 0.03 mol% (number average molecular weight 700000g / mol), 2 parts by mass of methyl vinyl silicone rubber with a vinyl content of 4.0 mol% (number average molecular weight 500000g / mol) mol), 50 mass parts specific surface area 200m 2 / g of fumed silica, 9 parts by mass of hydroxyl silicone oil with a hydroxyl content of 5.0 wt%, 0.5 parts by mass of hydrogen-containing silicone oil with a hydrogen content of 1.5 wt%, and 1.5 parts by mass of N-phenyl-3-aminopropyl trimethyl Add oxysilane to the kneader, knead for 2 hours, then raise the temperature to 160°C and knead for 2 hours, then vacuumize and knead at 130°C for 0.5h, cool to room temperature, and obtain the silicone rubber base rubber;

[0050] 2) the silicone rubber base rubber of step 1), 0.3 parts by mass of boron oxide wit...

Embodiment 3

[0053] A kind of lightweight porcelainable silicone rubber, its preparation method comprises the following steps:

[0054] 1) 95 parts by mass of methyl vinyl silicone rubber with a vinyl content of 0.08mol% (number average molecular weight 500000g / mol), 5 parts by mass of methyl vinyl silicone rubber with a vinyl content of 2.0mol% (number average molecular weight 700000g / mol) mol), 30 mass parts specific surface area 300m 2 / g of fumed silica, 5 parts by mass of hydroxyl silicone oil with a hydroxyl content of 10.0wt%, 0.9 parts by mass of hydrogen-containing silicone oil with a hydrogen content of 1.0wt%, and 3 parts by mass of γ-aminopropyltriethoxysilane added Kneader, knead for 1 hour, then heat up to 140°C and knead for 4 hours, then vacuumize and knead at 120°C for 1.5 hours, cool to room temperature, and obtain the silicone rubber base glue;

[0055] 2) The silicone rubber base rubber of step 1), 0.8 parts by mass of boron oxide with an average particle diameter of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com