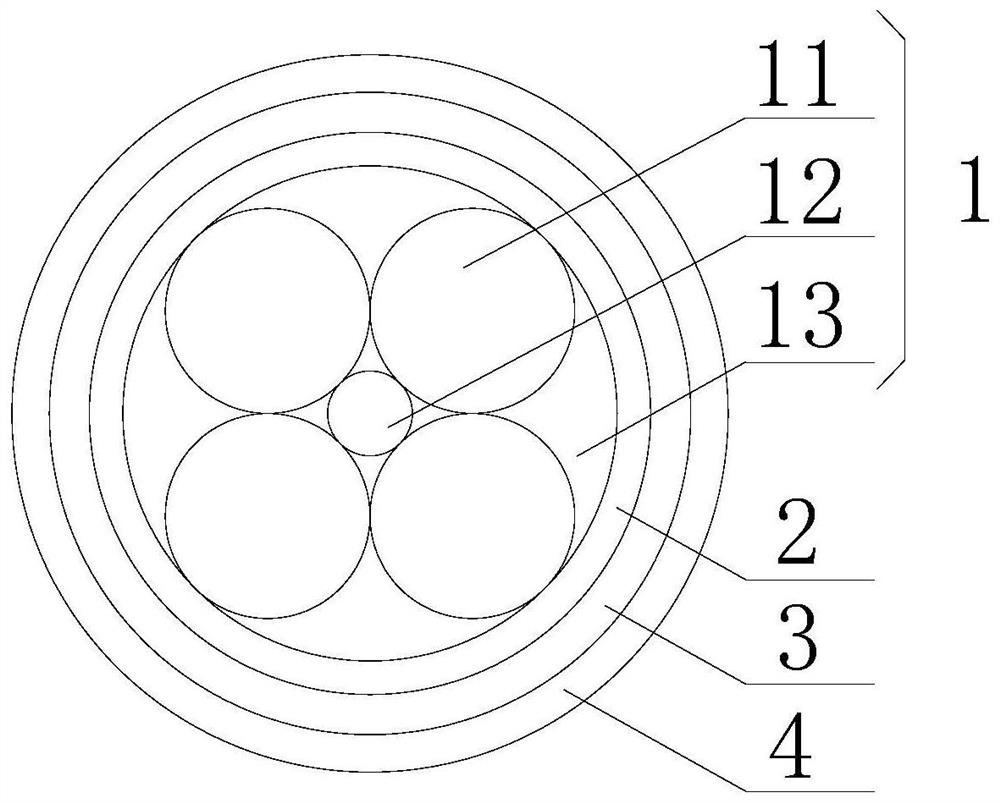

Flexible control cable for industrial robot

A flexible and soft polyvinyl chloride technology, used in insulated cables, bendable cables, cables, etc., can solve the problems of complex mechanical structure, poor heat resistance, and easy rupture of the cable surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

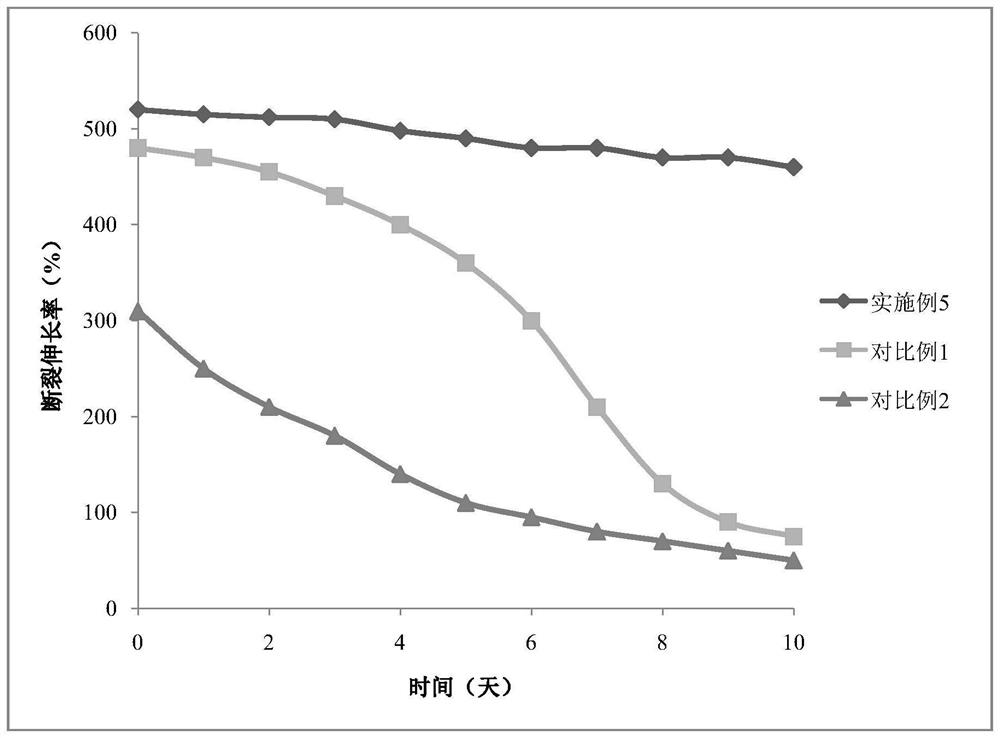

Embodiment 1

[0042] A flexible heat-resistant soft polyvinyl chloride plastic, its raw materials include: 100kg polyvinyl chloride, 5kg hyperbranched plasticizing carrier, 4kg pentaerythritol ester, 30kg tetrahydrofuran, 1kg calcium zinc stabilizer;

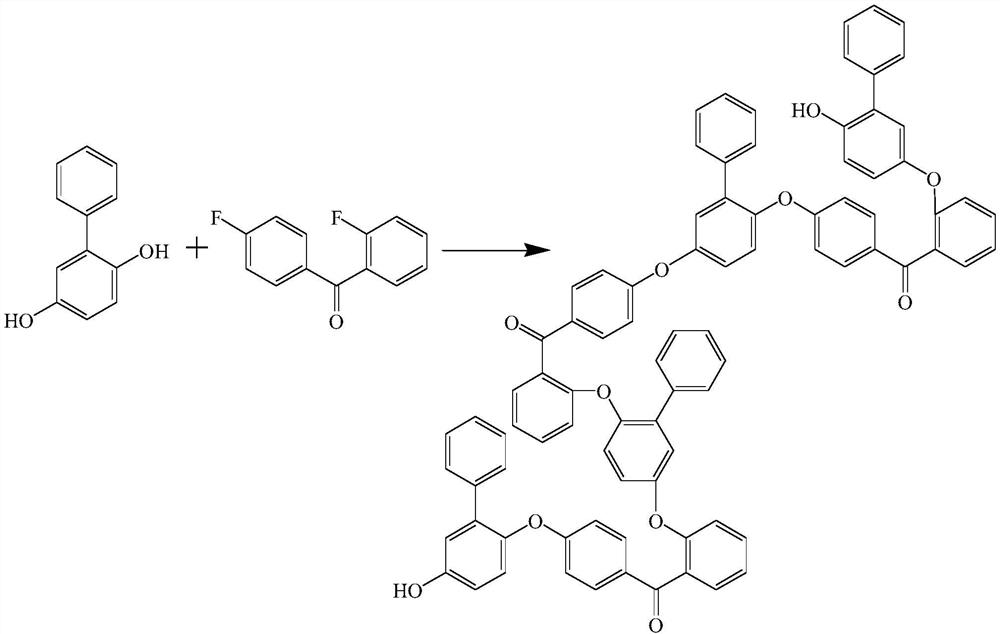

[0043] The hyperbranched plasticized carrier is prepared by the following process. Under the heated state of the reactor, the reactor is repeatedly evacuated and nitrogen is blown to remove the air and water in the reactor. Add 30kg of dichloromethane and mix evenly, adjust the temperature to 40°C, add 5kg of 3-ethyl-3-hydroxymethylbutylene oxide into the syringe, add it dropwise to the reactor under stirring, control the stirring speed Over 50r / min, after the dropwise addition is complete, keep stirring for 1 hour, use ethanol to terminate the reaction, and spin the solution to obtain a hyperbranched plasticized carrier.

[0044] Among them, the hydroxyl-terminated rigid initial unit is prepared by the following process. The reactor is repea...

Embodiment 2

[0050] A flexible heat-resistant soft polyvinyl chloride plastic, its raw materials include: 100kg polyvinyl chloride, 15kg hyperbranched plasticizing carrier, 10kg pentaerythritol ester, 50kg tetrahydrofuran, 2kg calcium zinc stabilizer;

[0051] The hyperbranched plasticized carrier is prepared by the following process. Under the heated state of the reactor, the reactor is repeatedly evacuated and nitrogen gas is used to remove the air and water in the reactor. Add 50kg of dichloromethane and mix evenly, adjust the temperature to 50°C, add 15kg of 3-ethyl-3-hydroxymethylbutylene oxide into the syringe, add it dropwise to the reactor under stirring, control the stirring speed Over 50r / min, after the dropwise addition is complete, keep stirring for 2 hours, use ethanol to terminate the reaction, and spin the solution to obtain a hyperbranched plasticized carrier.

[0052] Among them, the hydroxyl-terminated rigid initial unit is prepared by the following process. The reactor i...

Embodiment 3

[0058] A flexible heat-resistant soft polyvinyl chloride plastic, its raw materials include: 100kg polyvinyl chloride, 8kg hyperbranched plasticizing carrier, 5kg pentaerythritol ester, 35kg tetrahydrofuran, 1.2kg calcium zinc stabilizer;

[0059] The hyperbranched plasticized carrier is prepared by the following process. Under the heated state of the reactor, the reactor is repeatedly evacuated and nitrogen is blown to remove the air and water in the reactor. Add 35kg of dichloromethane and mix evenly, adjust the temperature to 42°C, add 8kg of 3-ethyl-3-hydroxymethylbutylene oxide into the syringe, add it dropwise to the reactor under stirring, control the stirring speed Over 50r / min, after the dropwise addition is complete, keep stirring for 1.2h, use ethanol to terminate the reaction, and spin the solution to obtain a hyperbranched plasticized carrier.

[0060] Among them, the hydroxyl-terminated rigid initial unit is prepared by the following process. The reactor is repea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com