Preparation method of high-temperature-resistant graphite material

A technology of graphite material and high temperature resistance, which is applied in the field of preparation of high temperature resistant graphite materials, can solve the problems of long production cycle, cumbersome processing process, easy oxidation, etc., and achieve high temperature oxidation resistance, simple preparation process, and good bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

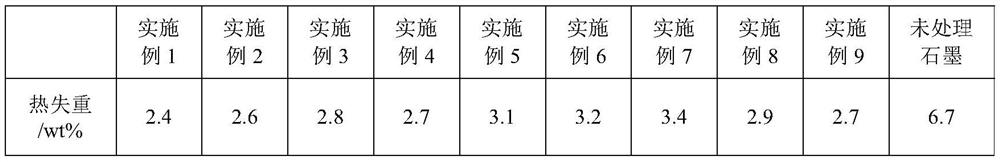

Examples

preparation example Construction

[0020] A preparation method of a high temperature resistant graphite material, comprising the following three stages:

[0021] First, the preprocessing stage:

[0022] The graphite is washed with distilled water and alcohol for 10-15 minutes in turn, and then filtered and dried for later use to remove impurities on the surface of the graphite.

[0023] The particle size of the graphite used above is 150-500 μm, and the carbon content in the graphite is ≥94 wt %.

[0024] Second, the inorganic salt impregnation stage:

[0025] 1) Weigh 2~12g of sodium tetraborate and sodium dihydrogen phosphate, then add 20~30ml of distilled water at 90~100°C, fully stir and mix until transparent, then add 1~5ml of phosphoric acid, stir well to prepare dipping solution A .

[0026] The purities of sodium tetraborate, sodium dihydrogen phosphate and phosphoric acid used above are all analytically pure, with a purity of 99.9%.

[0027] 2) Add 2-10 g of graphite into impregnation solution A fo...

Embodiment 1

[0032] A preparation method of high temperature resistant graphite.

[0033] 1) First weigh 10 g of sodium tetraborate and sodium dihydrogen phosphate, then add 20 ml of distilled water at 90 to 100°C, stir and mix until transparent, add 5 ml of phosphoric acid, and stir thoroughly to obtain dipping solution A.

[0034] 2) Add 2-10 g of graphite into the impregnation solution A for dipping, heat to 75°C, keep the temperature constant for 3 hours, filter, and dry at 80°C for 12 hours to obtain mixture B.

[0035] 3) The mixture B is placed in a muffle furnace, and heat-treated at 120-400° C. for 1-2 hours to obtain a high-temperature resistant graphite material.

Embodiment 2

[0037] A preparation method of high temperature resistant graphite.

[0038] 1) First weigh 8 g of sodium tetraborate and sodium dihydrogen phosphate, then add 20 ml of distilled water at 90 to 100°C, stir and mix until transparent, then add 4 ml of phosphoric acid, and stir thoroughly to prepare immersion solution A.

[0039] 2) Add 2 to 10 g of graphite into the impregnation solution A for dipping, heat to 75°C, keep the temperature constant for 3 hours, filter, and dry at 85°C for 13 hours to obtain mixture B.

[0040] 3) The mixture B is placed in a muffle furnace, and heat-treated at 120-400° C. for 1-2 hours to obtain a high-temperature resistant graphite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com