A fully automatic quality control system

A fully automatic, control system technology, applied in the registration/instruction quality control system, comprehensive factory control, closed-circuit television system, etc., can solve the problems of placement disorder, manual operation error, writing error, etc., to achieve convenient operation and ensure accuracy Sexuality and easy machine recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

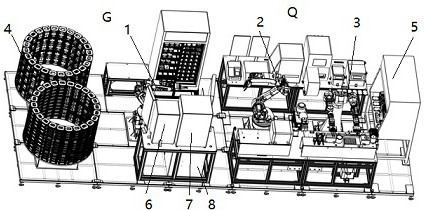

[0070] Such as figure 1 A schematic diagram of the structure of an automatic quality control system is shown. In this embodiment, a fully automatic quality control system includes a product storage area, a quality inspection area and a control system arranged in a positive pressure environment (using a positive pressure air outlet).

[0071] The goods storage area is provided with a number of goods, a robotic arm A1 for operating the goods, and a camera system A for monitoring the manipulation of the robotic arm A1.

[0072] The quality inspection area is provided with several quality inspection devices for quality inspection of goods, at least one robot arm B2 that accepts the goods transmitted by the robot arm A1 and operates the quality inspection device to perform quality inspection on the goods, and The robot arm B2 manipulates and monitors the camera system B25. The camera system A (or camera system B25) can be a camera located at the top of the cargo storage area, or ...

Embodiment 2

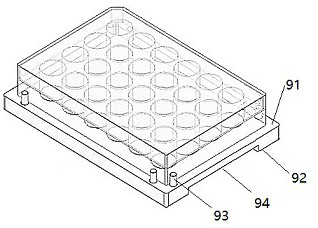

[0086] Such as image 3 A schematic diagram of the first structure of the carrying device 9 of the present application is shown.

[0087] In the process of goods transmission, it needs to be transported from the shelf 43 to each area to meet the quality inspection requirements. In order to unify the structure, it is convenient for the precise operation of the robot arm A1, the robot arm B2 or the robot arm C3. In some embodiments, the goods are carried by the carrying device 9 during the conveying process. The carrying device 9 of the present application can facilitate experimental operations such as gripping, transferring, storing, and tilting of the robot arm, and the whole process remains stable without affecting the aseptic state in the orifice plate. For the first time, the use of containers such as orifice plates has been transformed from manual operation to automatic detection.

[0088] In some embodiments, the carrying device 9 has an upper carrying surface 91 and a ...

Embodiment 3

[0099] The goods storage area and the quality inspection area are arranged separately to ensure the independence and freedom of the respective work of the robotic arms in the two, and to avoid crosstalk between the robotic arms in the two. Of course, in other embodiments, if the interference between different robot arms can be avoided through the design of the control program, the goods storage area and the quality inspection area can also adopt other layouts suitable for specific experimental environments.

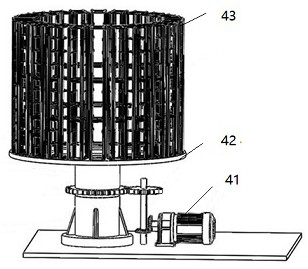

[0100] The goods storage area is provided with a rotating shelf 4, a refrigerator group, an incubator and a robot arm A1. In some embodiments, in order to facilitate the layout and the positioning of the operation site by the robot arm A1, the rotating shelf 4, the refrigerator group (such as a 4°C refrigerator, a -20°C refrigerator 8 and a -80°C refrigerator Box 7) and cell culture box 6 are arranged around three surfaces in the rotation direction of the robot arm A1. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com