Sagger containing calcium hexaluminate composite layer and preparation method of sagger

A calcium hexaaluminate and composite layer technology, which is applied in the field of composite layer saggers, can solve the problems of cracks in the composite layer, complex production process, high cost of zirconia, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of a sagger with a calcium hexaaluminate composite layer, comprising the following steps:

[0033] Step 1. In terms of mass fraction, weigh 10-30% of calcium hexaaluminate, 40-60% of magnesium-aluminum spinel, 15-30% of alumina, 5-20% of mullite, and 5-20% of kaolin , and the binder, placed in a mixer and stirred until uniformly mixed, and aged to obtain calcium hexaaluminate composite layer powder;

[0034] Step 2. When the sagger is broken and pressed, first use a brush to clean the lower mold surface of the mold;

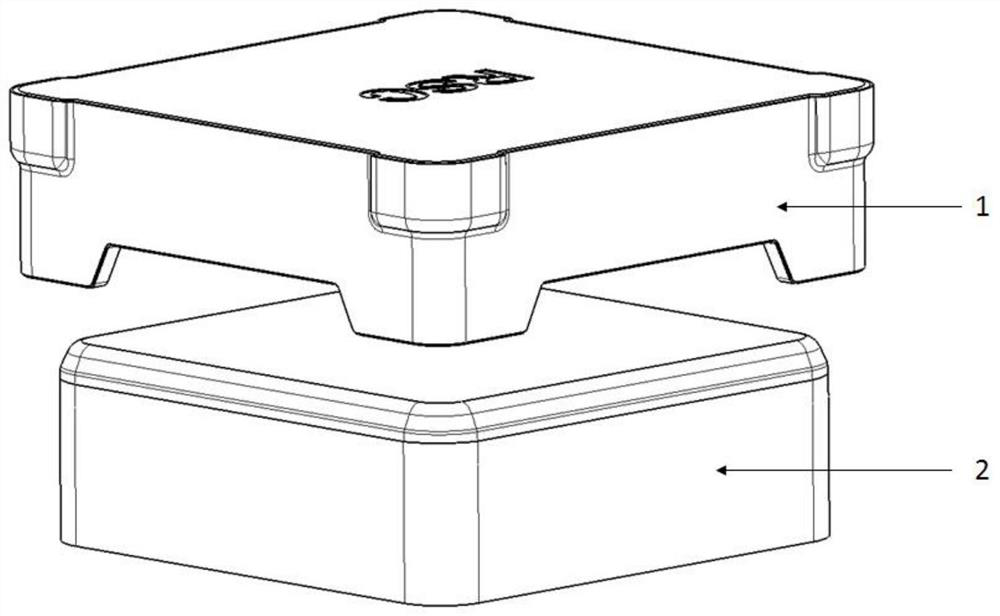

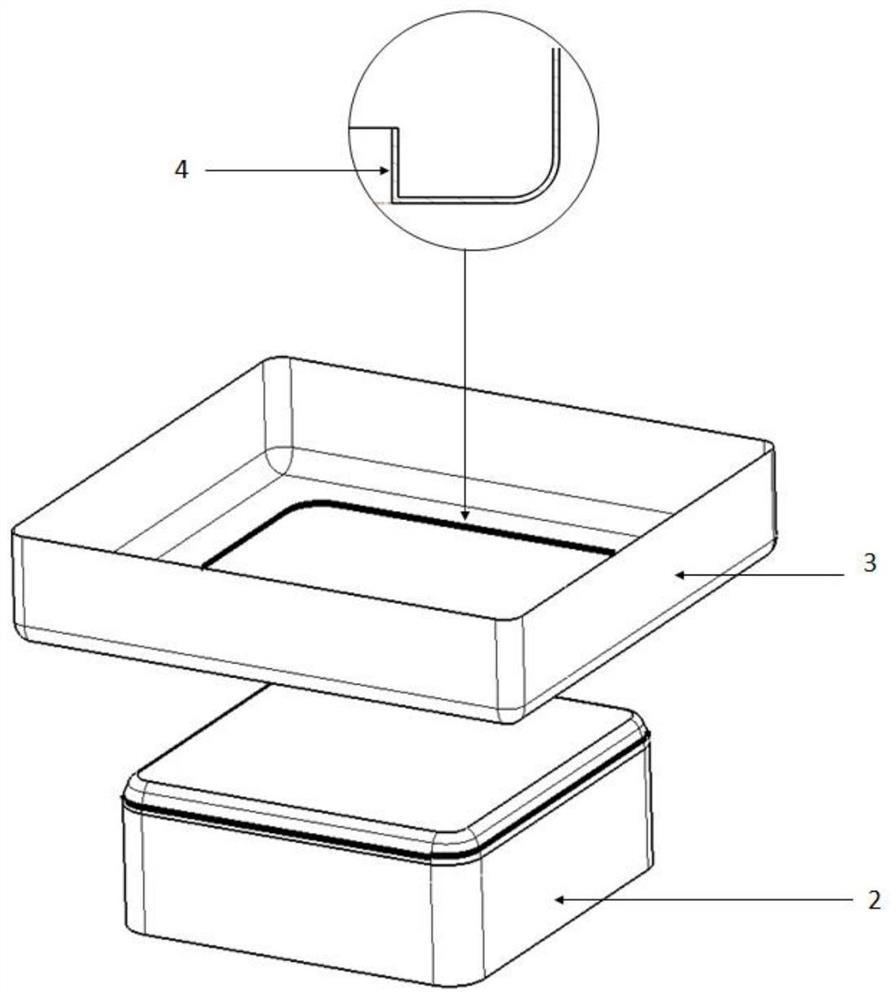

[0035] Among them, the mold requirements: the opening of the sagger product is facing downward when the mold is opened, and the lower mold surface 2 of the mold is installed on the lower template of the press;

[0036] Tooling design requirements: composite layer powder is applied to the inner opening of the tooling 3, set on the lower die surface 2 of the mold, and the material stopper 4 is bent so...

Embodiment 1

[0042] A sagger containing a calcium hexaaluminate composite layer, including composite layer powder, the components of the composite layer powder are calculated by mass percentage: calcium hexaaluminate 5-18% by weight, magnesium aluminum tip Crystal 25%-50%wt%, alumina 10-20%wt%, mullite 10-35%wt%, kaolin 5-10%wt%, polyvinyl alcohol solution 5-8%wt% (concentration is 3~5wt%),

[0043]

[0044]

[0045]Step 1, according to calcium hexaaluminate 15%wt%, magnesium aluminum spinel 40%wt%, alumina 15%wt%, mullite 20%wt%, kaolin 5%wt%, polyvinyl alcohol solution 5% wt% (concentration is 3 to 5wt%) for mixing, and the mixture is placed in a mixer to stir until the mixture is uniform, and after aging for 24 hours, calcium hexaaluminate composite layer powder is obtained;

[0046] Step 2. When the sagger green embryo is pressed, first use a brush to clean the lower mold surface of the mold, and then use the composite powder to apply tooling 3. Fill the powder made in step 1 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com