Spray coating process for protecting gas film hole of gas turbine blade

A technology of gas turbine blades and gas film holes, which is applied in coatings, spray devices, and devices for coating liquid on surfaces, etc., can solve the problems of high equipment cost, gas film hole shrinkage, complicated processes, etc., and achieve anti-corrosion performance. Good, prevent blocking and shrinkage phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

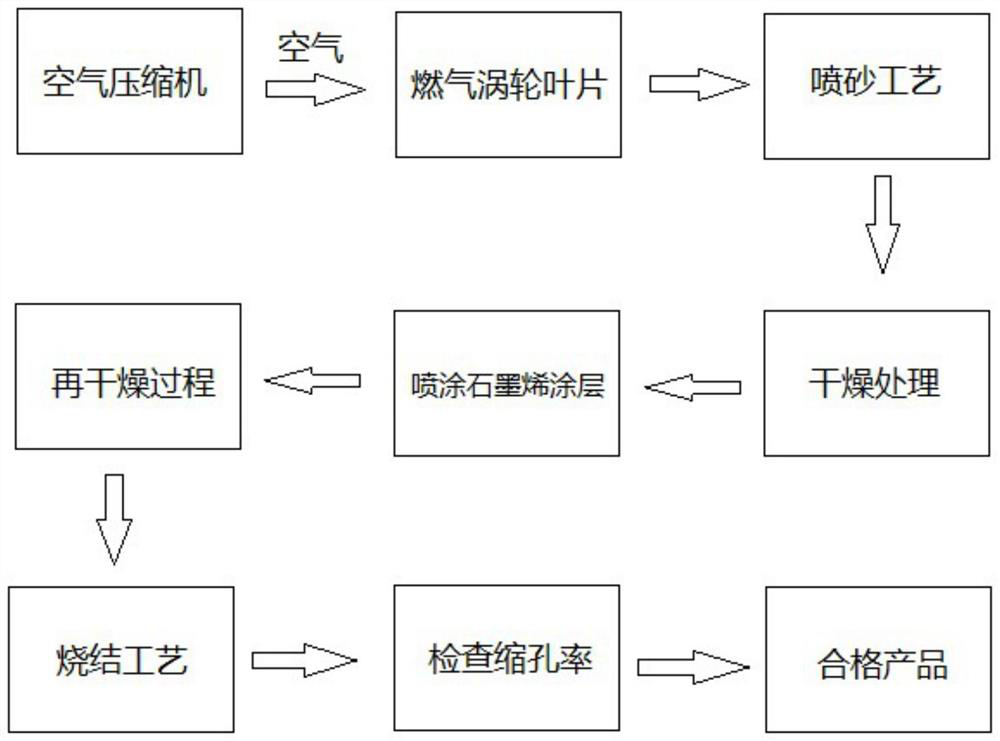

[0033] A spraying process for protecting gas turbine blade gas film holes, comprising the following steps:

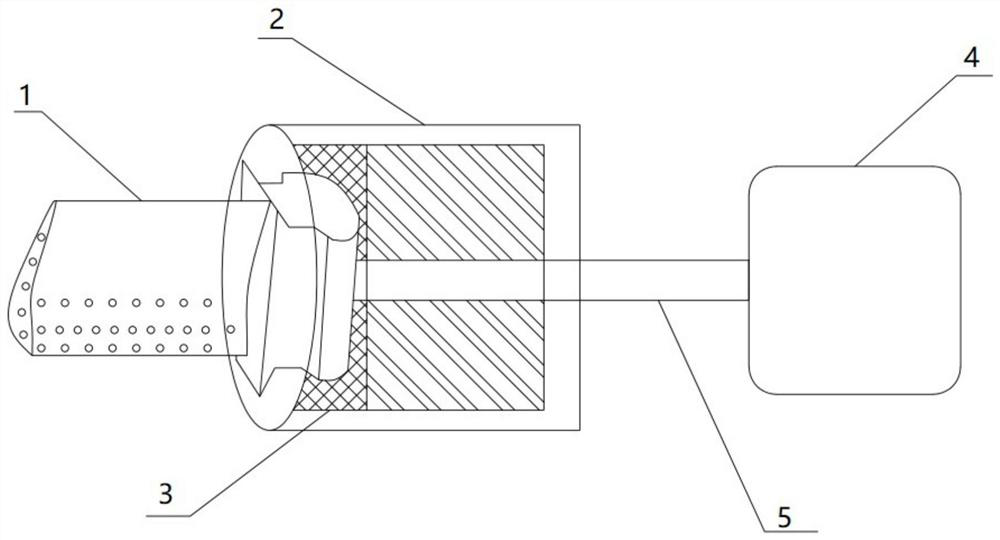

[0034] (1) Insert the tenon of the gas turbine blade 1 into the plaster protection mold 3 to protect the original size and shape of the tenon during sandblasting and spraying.

[0035] (2) The gypsum protection mold 3 is nested into the metal protection mold 2 made of alloy steel. The metal protection mold 2 is used to resist external force and prevent deformation of the entire device during the sandblasting process.

[0036] (3) Select the dry air compressor 4, and its air outlet passes through the metal protective mold 2 to be connected to the gas turbine blade, adjust the pressure of the dry air compressor 4 to be 0.1Mpa, and the dry compressed air enters the turbine blade 1, Then it is sprayed at the air film hole, and the continuous injection of gas can prevent the sand particles in the sandblasting and the paint in the spraying from blocking the air film hole.

...

Embodiment 2

[0042] A spraying process for protecting gas turbine blade gas film holes, comprising the following steps:

[0043] (1) Insert the tenon of the gas turbine blade 1 into the plaster protection mold 3 to protect the original size and shape of the tenon during sandblasting and spraying.

[0044] (2) The gypsum protection mold 3 is nested into the metal protection mold 2 made of alloy steel. The metal protection mold 2 is used to resist external force and prevent deformation of the entire device during the sandblasting process.

[0045] (3) Select the dry air compressor 4, and its air outlet passes through the metal protective mold 2 to be connected to the gas turbine blade, adjust the pressure of the dry air compressor 4 to be 0.1Mpa, and the dry compressed air enters the turbine blade 1, Then it is sprayed at the air film hole, and the continuous injection of gas can prevent the sand particles in the sandblasting and the paint in the spraying from blocking the air film hole.

...

Embodiment 3

[0051] A spraying process for protecting gas turbine blade gas film holes, comprising the following steps:

[0052] (1) Insert the tenon of the gas turbine blade 1 into the plaster protection mold 3 to protect the original size and shape of the tenon during sandblasting and spraying.

[0053] (2) The gypsum protection mold 3 is nested into the metal protection mold 2 made of alloy steel. The metal protection mold 2 is used to resist external force and prevent deformation of the entire device during the sandblasting process.

[0054] (3) Select the dry air compressor 4, and its air outlet passes through the metal protective mold 2 to be connected to the gas turbine blade, adjust the pressure of the dry air compressor 4 to be 0.1Mpa, and the dry compressed air enters the turbine blade 1, Then it is sprayed at the air film hole, and the continuous injection of gas can prevent the sand particles in the sandblasting and the paint in the spraying from blocking the air film hole.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com