Method for preparing porous Bi5O7I material in inert atmosphere

A technology of inert atmosphere and bismuth salt, which is applied in the field of porous photocatalytic material preparation, can solve the problem that porous Bi has not yet been retrieved, and achieve the effect of being suitable for mass industrial production, easy process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

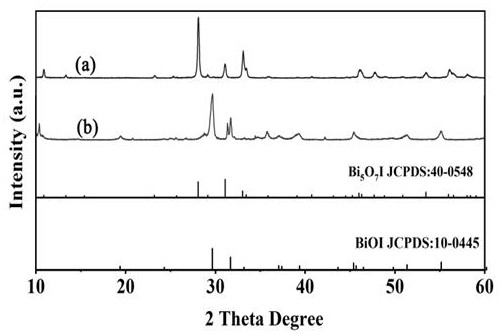

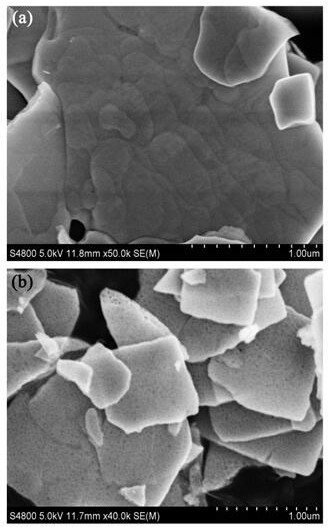

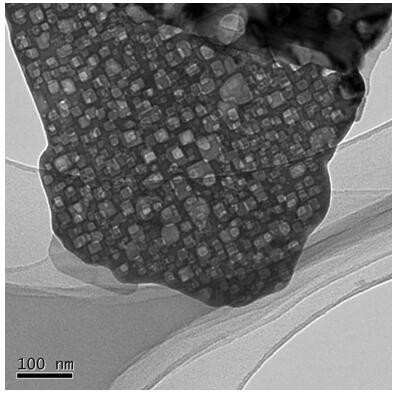

[0026] Ultrasonic disperse 4mmol of bismuth nitrate in 30ml of deionized water, stir well to form solution A; dissolve 4mmol of potassium iodide in 30ml of deionized water to form solution B; quickly pour solution B into solution A, adjust pH=1.5 and stir for 40min. Transfer the mixed solution into a 100ml hydrothermal reaction kettle, conduct a hydrothermal reaction at 160°C for 6 hours, cool, centrifuge, and wash to obtain sample S2. The S2 sample was transferred to a tube furnace under an argon atmosphere and kept at 450°C for 60 minutes to obtain a pale yellow porous Bi5O7I sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com