Method for reinforcing surface of zirconium-based amorphous alloy through laser irradiation of silicon carbide particles

A technology of zirconium-based amorphous alloy and silicon carbide particles, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve complex manufacturing process, poor bonding quality of reinforcement phase and amorphous matrix interface, The tensile plasticity and mechanical properties of crystal alloy composites are difficult to control and other problems, so as to achieve the effect of simple processing and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

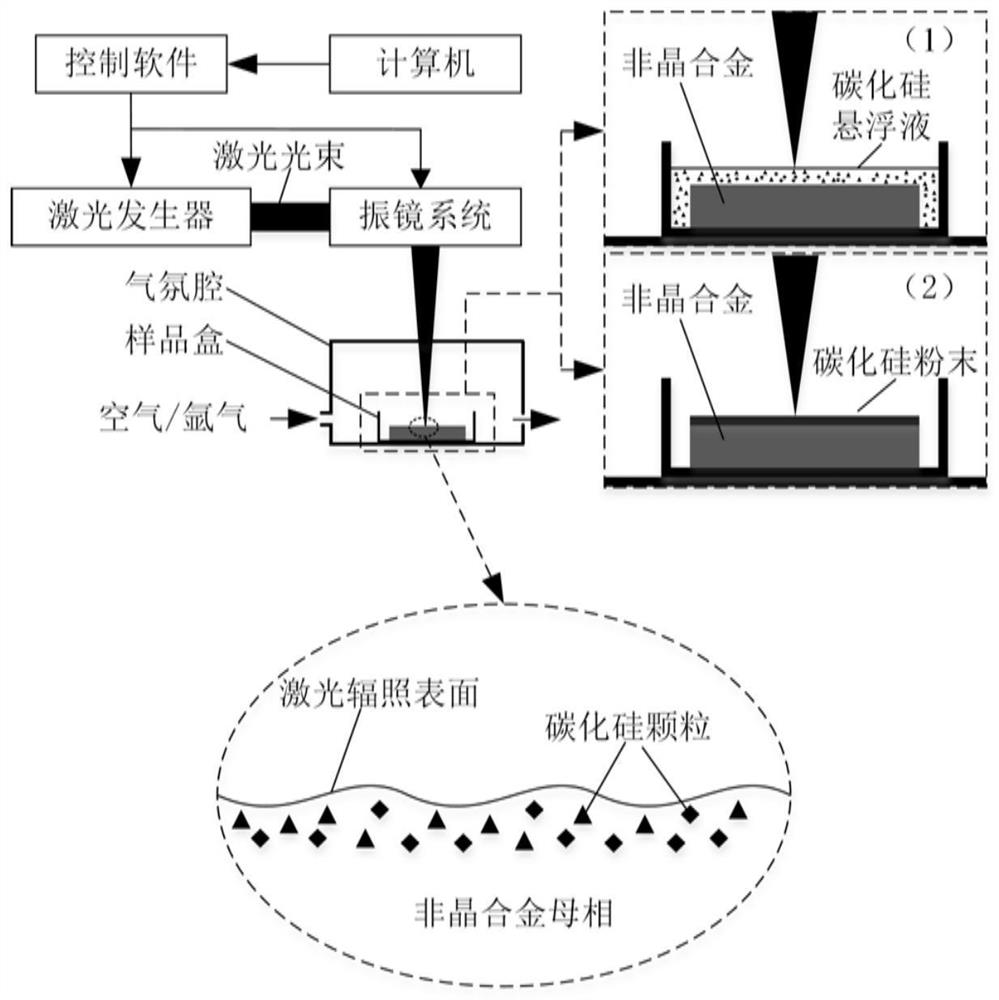

[0029] A typical zirconium-based amorphous alloy Zr 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 As an example, in an argon atmosphere, a nanosecond laser is used to irradiate the surface of a zirconium-based amorphous alloy covered with a silicon carbide suspension, and the specific implementation steps are as follows:

[0030] 1) Grinding and polishing the surface of the zirconium-based amorphous alloy with a size of 20mm×20mm and a thickness of 2mm, and cleaning and drying;

[0031] 2) Prepare a silicon carbide suspension with a mass fraction of 30%, pour it into a sample box with a zirconium-based amorphous alloy, and control the height between the liquid level and the surface of the zirconium-based amorphous alloy to be <1mm;

[0032] 3) Place the sample box in the atmosphere chamber, and pass argon into the atmosphere chamber;

[0033] 4) Use a nanosecond laser to irradiate the surface of zirconium-based amorphous alloy covered with silicon carbide suspension, where the laser...

Embodiment 2

[0038] A typical zirconium-based amorphous alloy Zr 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 For example, in an argon atmosphere, a nanosecond laser is used to irradiate the surface of a zirconium-based amorphous alloy covered with silicon carbide powder. The specific implementation steps are as follows:

[0039] 1) Grinding and polishing the surface of the zirconium-based amorphous alloy with a size of 20mm×20mm and a thickness of 2mm, and cleaning and drying;

[0040] 2) Prepare a silicon carbide suspension with a mass fraction of 10%, inject it into a sample box containing a zirconium-based amorphous alloy, and control the height between the liquid level and the surface of the zirconium-based amorphous alloy to be <1mm; place the sample box in a dry place Put it aside in a dusty environment for 2-3 days until the water evaporates;

[0041] 3) Place the sample box in the atmosphere chamber, and pass argon into the atmosphere chamber;

[0042] 4) Use a nanosecond laser to irr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com