Surfactin high-yield bacillus subtilis obtained through compound mutation and fermentation method thereof

A technology for bacillus subtilis and mutagenic strains, applied in the field of microorganisms, can solve the problems of high production cost, limited industrial production, low biosynthesis efficiency, etc., and achieves high mutagenesis power, good application and promotion prospects, and enhanced foaming performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 Surfactin high-yield strain compound mutagenesis selection

[0045] S1. Strain preservation: the starting strain Bacillus subtilis subsp.Subtilis (Bacillus subtilis subsp.Subtilis, resource number: BNCC 194013) was cultured to the logarithmic phase with nutrient broth medium (NB), and the bacterial solution was mixed with glycerol at 1:1. Mix well to make the final concentration of glycerol 50%. After pre-cooling in a refrigerator at 4°C, transfer to -20°C and -80°C low-temperature refrigerators.

[0046] S2. Ultraviolet mutagenesis: Pick the Bacillus subtilis strains on the inclined surface and inoculate them in NB medium, cultivate to the logarithmic phase, dilute the bacterial solution to a suitable gradient, smear the blood plate, and carry out ultraviolet mutagenesis, with no irradiation as the control . Except for the control group, they were all wrapped in black paper, cultured at 37°C for 24-48 hours, and the ratio of hemolytic zone to colony dia...

Embodiment 2

[0053] Embodiment 2 detects the performance of Surfactin high-yielding mutagenic strain

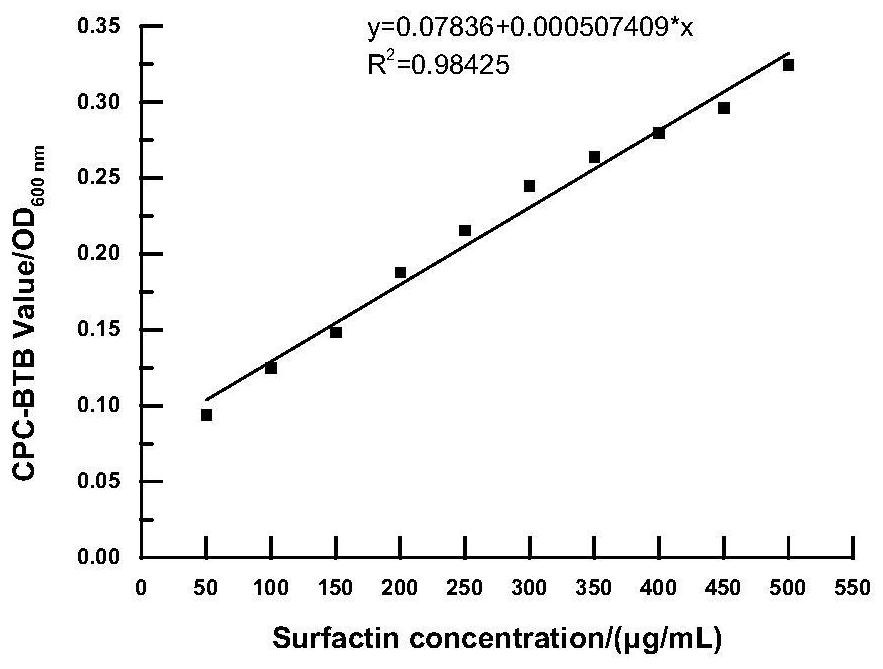

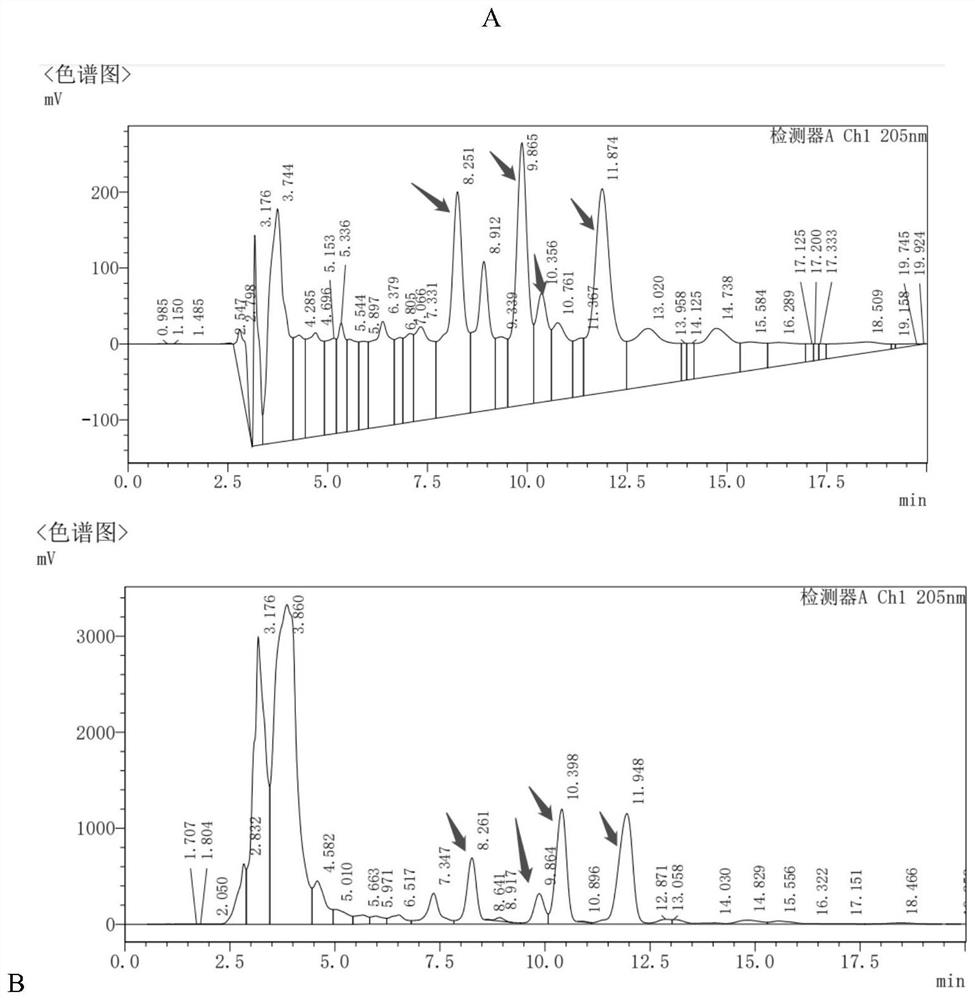

[0054] 1. Detection of surfactin production: Take FHYB201030 bacteria liquid in the logarithmic phase, add it to the fermentation medium according to the inoculum amount of 5%, ferment at 40°C for 72 hours, use CPC-BTB colorimetric method to detect, and finally determine the concentration of surfactin in the fermentation liquid as 10.91g / L. Adopt HPLC to measure output, the result is as follows figure 2 As shown, the yield of surfactin was 11.2g / L, and the purity of extracted surfactin was 98.82%.

[0055] 2. Determination of genetic stability of mutagenized strains:

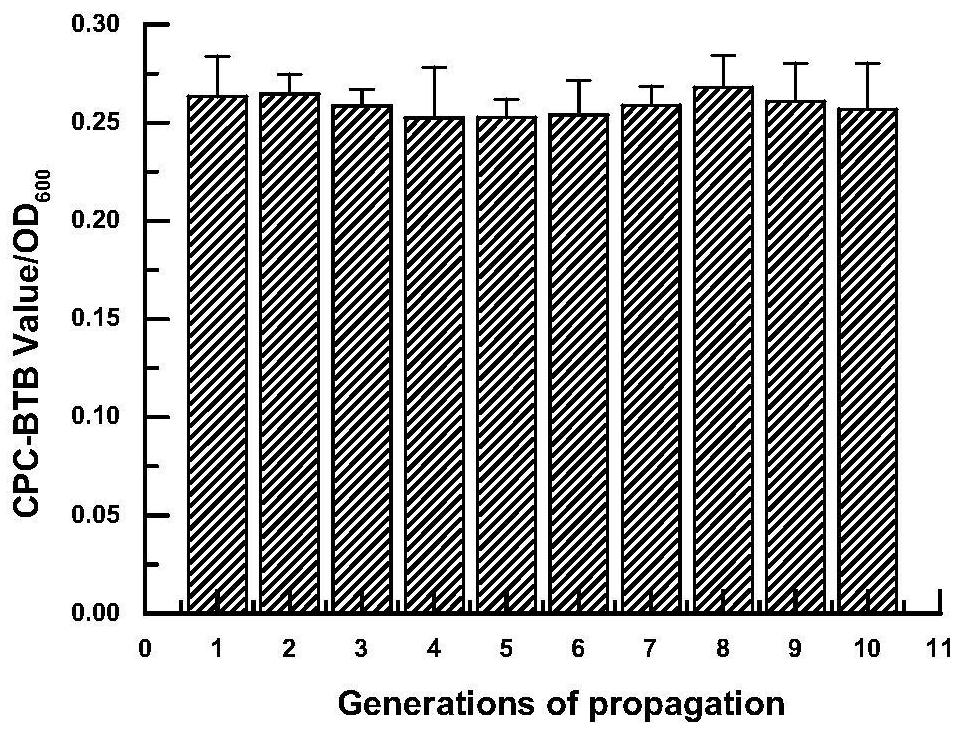

[0056] The high-yielding mutant strains screened by mutagenesis were subcultured on slant, and subcultured once every 24 hours for a total of 10 generations. The mutagenized strains were picked for each generation and fermented in shake flasks for 3 days. The passage of the strains was detected by the CPC-BTB colorimet...

Embodiment 3

[0074] Example 3 This example provides the fermentation method of the mutagenized strain of the present invention

[0075] The fermentation medium of the mutagenic strain of the present invention is: beef extract 3g / L, peptone 10g / L, NaCl 5g / L, maltose 15g / L, sorbitol 10g / L, yeast extract 40g / L, casein 30g / L, Lactose 35g / L, lactic acid 5mmol / L, glutamic acid 1g / L, MnSO4 1.5mmol / L, medium pH 7.0.

[0076] The fermentation conditions of the mutagenic strain of the present invention are as follows: the temperature is 40° C., the rotating speed is 250 rpm, and the liquid filling volume is 50%.

[0077] Fermentation method: inoculate the seed solution obtained from the mutagenized strain into the above-mentioned fermentation medium at an inoculation amount of 5%, and cultivate for 3 days according to the above-mentioned fermentation conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com