Aramid nanofiber-based composite aerogel and preparation method thereof

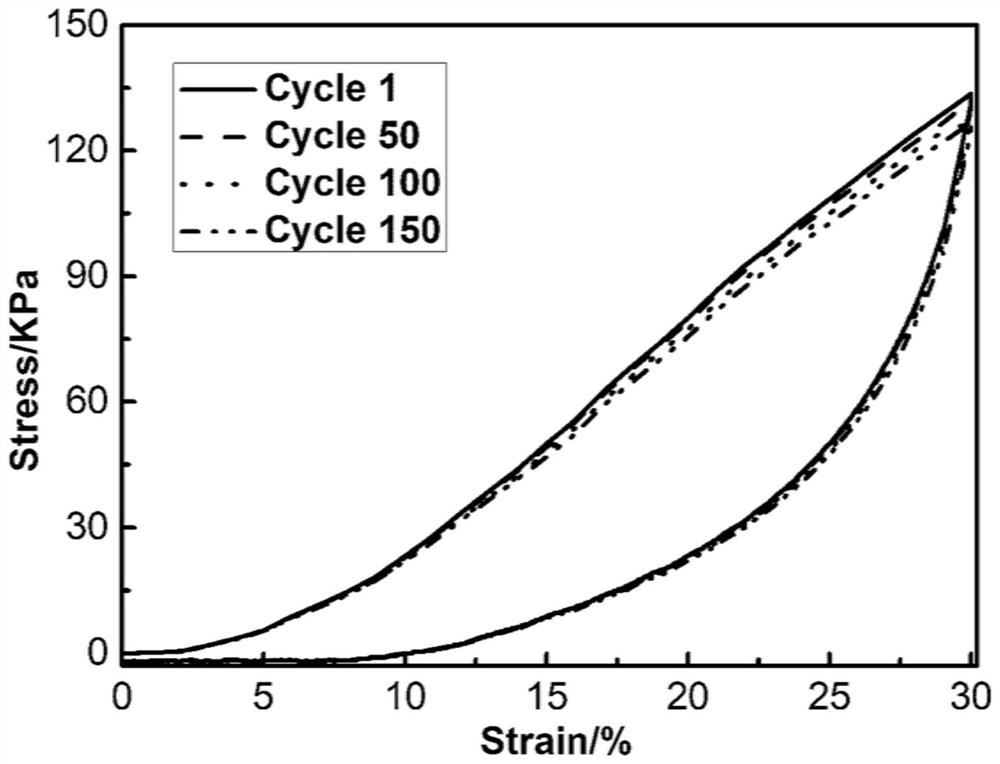

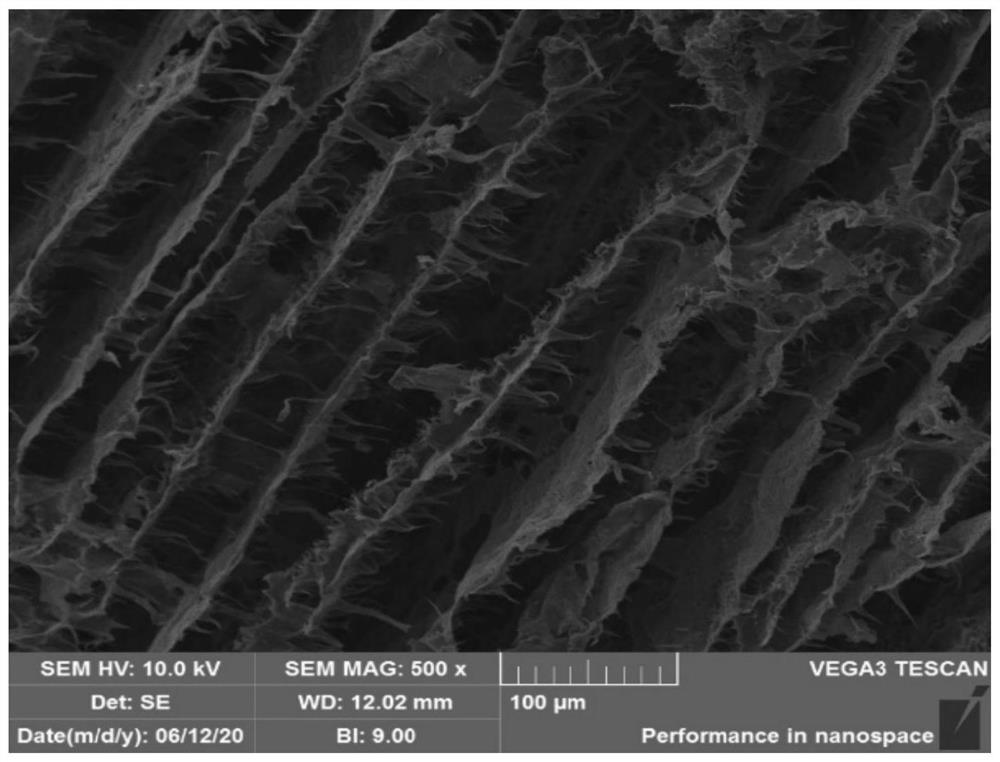

A composite airgel and nanofiber technology, which is applied in the field of aramid nanofiber-based composite aerogel and its preparation, can solve the problems of aramid nanofiber aerogels such as easy shrinkage, poor structural regularity, and difficult to stabilize performance. Achieve good compression cycle and mechanical properties, low thermal conductivity, and avoid shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing an aramid nanofiber-based composite airgel, comprising the following steps:

[0027] Step 1, preparing aramid nanofiber suspension; wherein, the preparation process of aramid nanofiber suspension is as follows:

[0028] Put aramid, dimethyl sulfoxide, potassium hydroxide and water in a container, stir and disperse to obtain aramid nanofibers; mix aramid nanofibers with water to obtain aramid nanofiber suspensions; preferably, aramid The fiber adopts polyparaphenylene terephthalamide.

[0029] Step 2, mixing the aramid nanofiber suspension with the polymer solution to obtain a mixed slurry; in the mixed slurry, the mass concentration of the aramid nanofiber suspension is 0.05%-5%; the quality of the polymer solution is aramid fiber 0.5%-30% of the nanofiber mass; wherein, the polymer solution is one of PVA solution, starch solution, chitosan solution and sodium alginate solution;

[0030] Step 3, freeze-drying the mixed slu...

Embodiment 1

[0033] This embodiment 1 provides a method for preparing an aramid nanofiber-based composite airgel, comprising the following steps:

[0034] Step 1, preparation of aramid nanofiber suspension

[0035] Put aramid, dimethyl sulfoxide, potassium hydroxide and water in a container, stir and disperse to obtain aramid nanofibers; mix aramid nanofibers with water to obtain aramid nanofiber suspension; aramid is made of poly P-phenylene terephthalamide; displacement of dimethyl sulfoxide in aramid nanofiber suspension by deionized water.

[0036] Step 2, preparation of polymer solution

[0037] Mix polyvinyl alcohol and deionized water and stir evenly to obtain a polyvinyl alcohol solution; wherein, the mass percentage of the polyvinyl alcohol solution is 10%.

[0038] Step 3, prepare mixed slurry

[0039] The aramid nanofiber suspension is mixed with the polyvinyl alcohol solution to obtain a mixed slurry; in the mixed slurry, the mass concentration of the aramid nanofiber suspen...

Embodiment 2

[0045] This embodiment 2 provides a kind of preparation method of aramid nanofiber-based composite airgel, comprising the following steps:

[0046] Step 1, preparation of aramid nanofiber suspension

[0047] Put aramid, dimethyl sulfoxide, potassium hydroxide and water in a container, stir and disperse to obtain aramid nanofibers; mix aramid nanofibers with water to obtain aramid nanofiber suspension; aramid is made of poly P-phenylene terephthalamide; displacement of dimethyl sulfoxide in aramid nanofiber suspension by deionized water.

[0048] Step 2, preparation of polymer solution

[0049] The chitosan is mixed with deionized water and stirred evenly to obtain a chitosan solution; wherein, the mass percentage of the chitosan solution is 5%.

[0050] Step 3, prepare mixed slurry

[0051] The aramid nanofiber suspension is mixed with the chitosan solution to obtain a mixed slurry; in the mixed slurry, the mass concentration of the aramid nanofiber suspension is 0.05%; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com