Expansive soil road cutting side slope reinforced soil back-pressure seepage-preventive supporting structure and construction method thereof

A technology of supporting structure and construction method, applied in basic structure engineering, excavation, construction, etc., can solve the problems of not meeting the requirements of the construction period, the rigidity of the protective structure can not meet the stability requirements of expansive soil, and it is only suitable for saving engineering cost. , the effect of shortening the construction period and reducing the transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

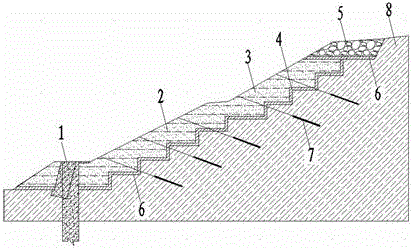

[0031] Expansive soil cutting high slope reinforced soil back pressure anti-seepage flexible slope protection structure, including: expansive soil cutting side slope 4 and slope toe supporting structure 1. The slope toe supporting structure 1 can be a gravity-type cutting wall, between piles Retaining walls and pile-slab walls. After the excavation of the slope surface is completed, a layer of geomembrane material is laid along the excavation surface, and the reinforced soil is backfilled after the paving is leveled. The reinforced material is a geogrid. When backfilling to 0.5m away from the top of the slope, use mortar and rubble to build the counter-pressure anti-seepage structure 5 of the top of the slope, and at the same time construct the slope protection structure.

Embodiment 2

[0033] The concrete steps for the construction method of the reinforced soil anti-seepage support structure of the expansive soil cutting slope are as follows: ①The site is leveled. Measure the top of the cut and remove the surface soil that needs to be excavated; ②When the construction equipment enters the site, the expansive soil slope must be excavated in the dry season. In order to ensure that the slope is not washed by rain and avoid prolonged exposure, rapid construction methods must be adopted , Centralized excavation with a collection of construction machines; ③Excavation step by step from the slope to the foot of the slope according to the design slope rate, and use different sizes of steps according to the different slope rate, the slope rate is 1:2.0, and the step width 4.0 meters, 2.0 meters high, slope ratio 1:1.75, steps width 3.5 meters, height 2.0 meters, slope ratio 1:1.5, steps width 3.0 meters, height 2.0 meters. Assuming that the expansive soil has a steep l...

Embodiment 3

[0035] Such as figure 1 The reinforced soil anti-pressure anti-seepage support structure shown, after the side slope is excavated once and formed, the slope toe supporting structure 1 and the slope protection structure (geogrid reinforced material 2, backfilled reinforced soil 3, Geomembrane 6, anchor rod 7), which greatly shortens the construction period and avoids prolonged exposure of expansive soil. Among them, the geogrid reinforcement material 2 is laid horizontally every 0.6m, and the composite geomembrane 6 is laid along the excavation surface and spread evenly to ensure a 0.5m overlap. The width and height of the excavated steps are determined according to the design slope rate, and the over-excavation depth is determined according to the depth of the expansive soil's acute atmospheric influence. The mortar and rubble counter-pressure anti-seepage structure 5 is set on the top of the slope to prevent the infiltration of surface water and keep the expansive soil of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com