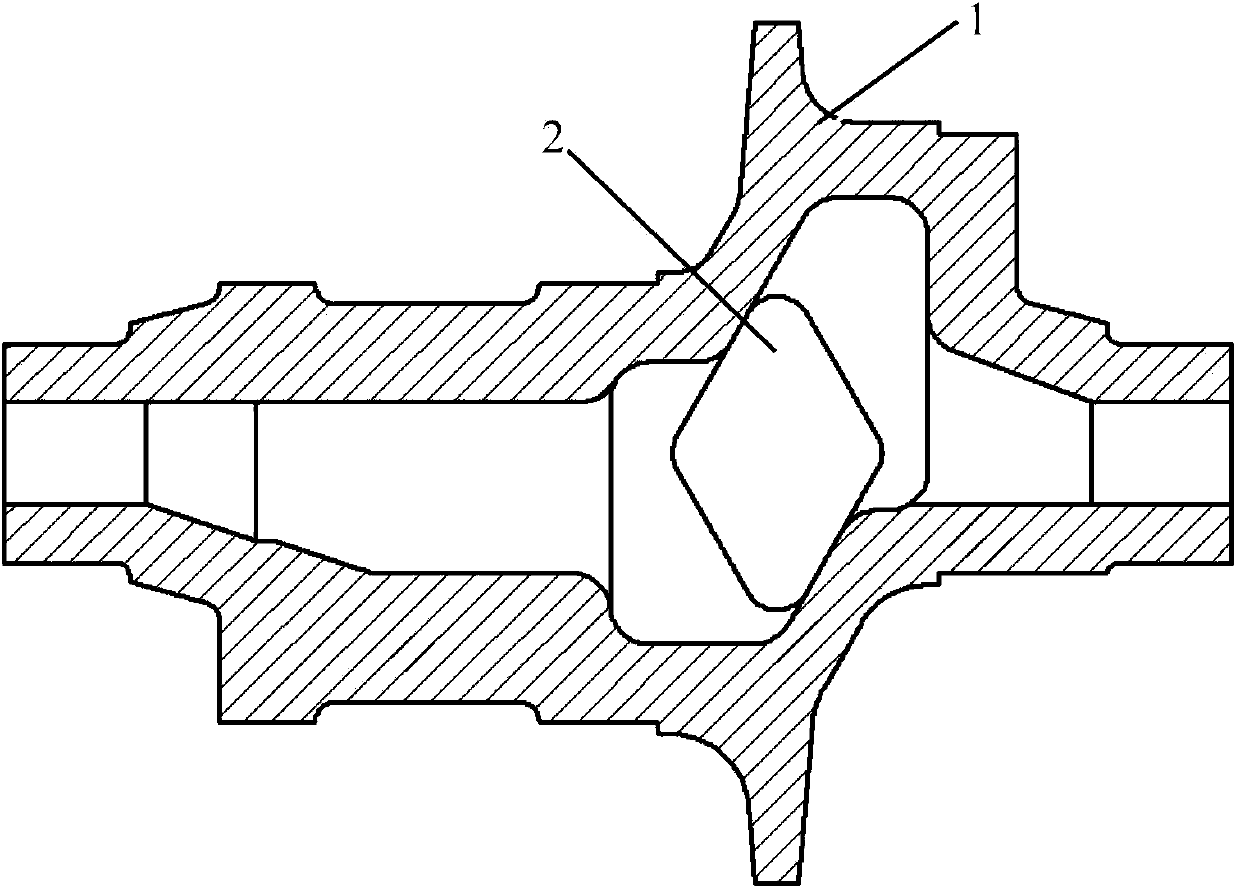

Casting method of hollow crankshaft of slurry pump

A hollow crankshaft and mud pump technology, which is applied to casting molding equipment, molds, mold components, etc., can solve the problems of crankshaft eccentricity, uneven wall thickness of floating core, unreasonable riser setting, shrinkage and other problems, and achieves Improve the quality of castings, improve the qualified rate of flaw detection, and prevent the sand core from breaking or deforming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Made F-1300 mud pump crankshaft, drawing number AH130101-02080001, produced a batch of serial numbers 12463, 12579, 12473, 12520, 12492, a total of 5 pieces, flaw detection report number: BOMCOJ69-MT-NA055-1301, flaw detection result: qualified.

[0059] The same production sequence number is 12384, 12476, a total of 2 pieces, flaw detection report number: BOMCOJ69-MT-NA025-1302, flaw detection result: qualified;

[0060] The production sequence number is 12557, 12537, a total of 2 pieces, flaw detection report number: BOMCOJ69-MT-NA030-1302, flaw detection result: qualified;

[0061] The production sequence number is 12531, 12555, a total of 2 pieces, flaw detection report number: BOMCOJ69-MT-NA031-1302, flaw detection result: qualified.

[0062] During the trial production process, the qualification rate of the crankshaft reached over 98%, which ensured the quality of the key main bearing parts of the mud pump.

[0063] The hollow crankshaft produced by the method of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com