Preparation method of terpolymer dispersing agent and application of terpolymer dispersing agent in preparation of liquid disperse dye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

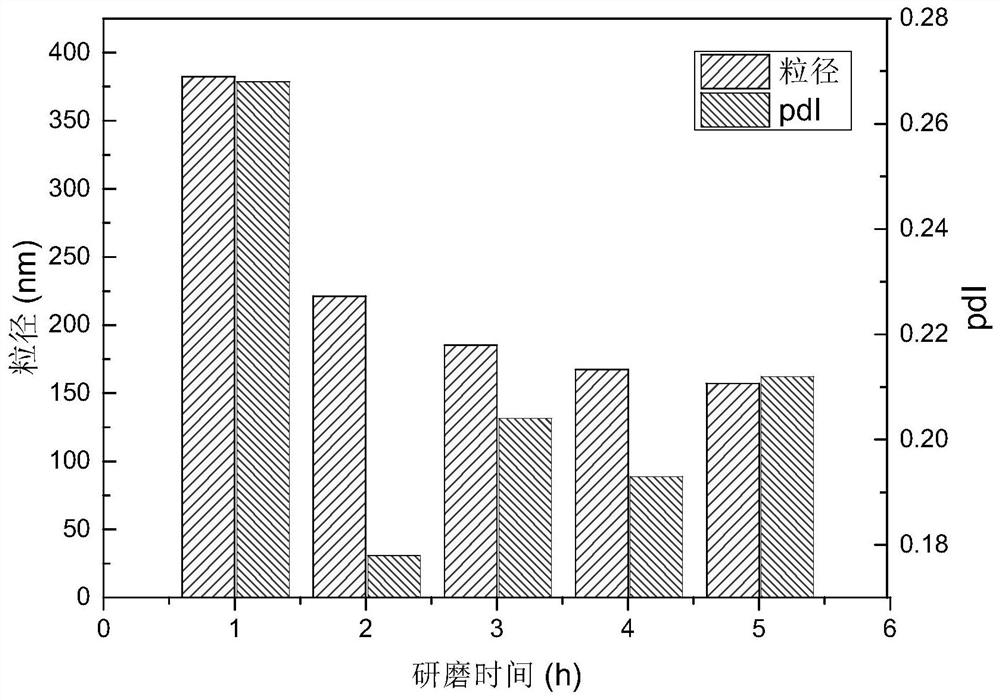

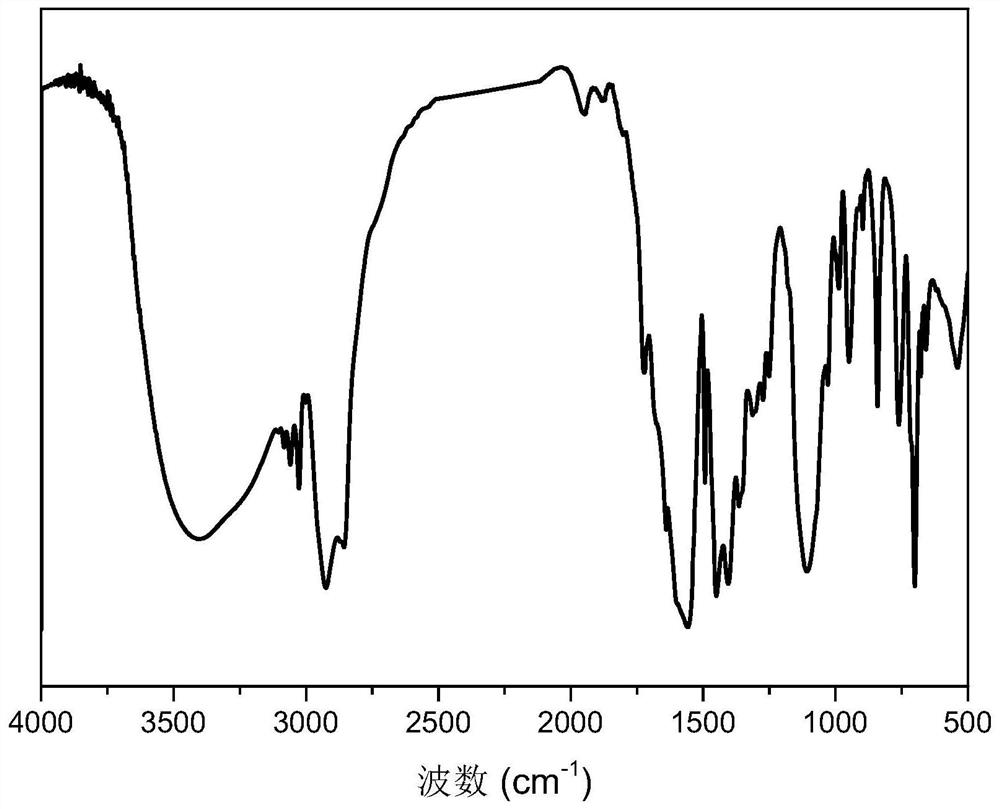

Method used

Image

Examples

Embodiment 1

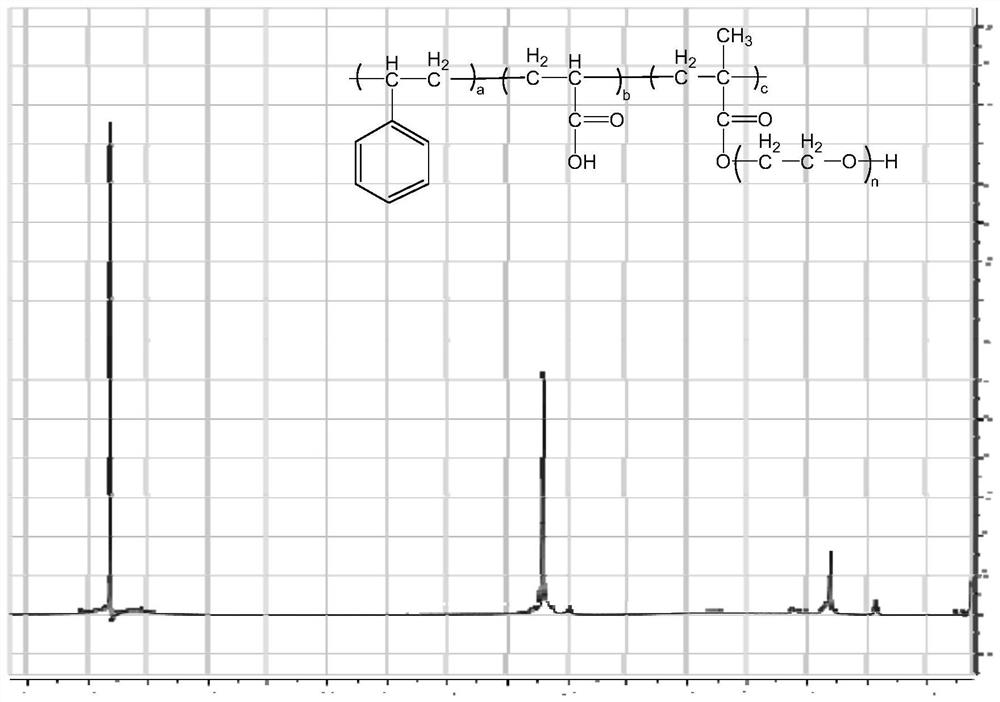

[0030] (1) Synthesis of polymer dispersant:

[0031]

[0032] Among them, n is 15.

[0033] Weigh three monomers of styrene, acrylic acid and methoxypolyethylene glycol methacrylate, dissolve them in isopropanol, mix them evenly, add them into the reaction flask and stir at a certain stirring rate, and fill the reaction flask with Nitrogen for 20 minutes to remove oxygen in the reaction device; dissolve the initiator in acetone, when the temperature rises to 60°C, add the initiator solution dropwise through a micro-injection pump and control the dropping time for 1 hour; when the initiator is added dropwise, Insulate and react at 80°C for 7 hours; after the reaction, cool down and add 30% sodium hydroxide solution dropwise to the reaction system to adjust the pH value of the system to about 7.5-8.0; discharge the solvent through a rotary evaporator under reduced pressure , and the product was washed with ether and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com