Low-volatility high-performance environment-friendly insulating resin and preparation method thereof

An insulating resin and environmentally friendly technology, which is applied in the field of low-volatile high-performance environmentally-friendly insulating resin and its preparation, can solve the problems of low volatile content and high volatile content of insulating impregnated resin, so as to reduce volatilization, reduce VOC content, and improve The effect of reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

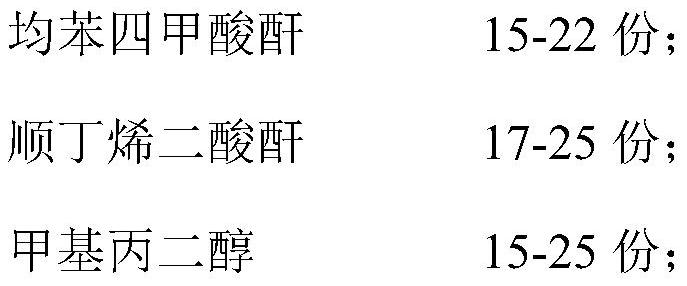

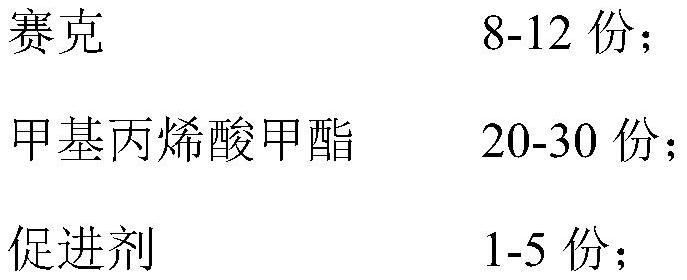

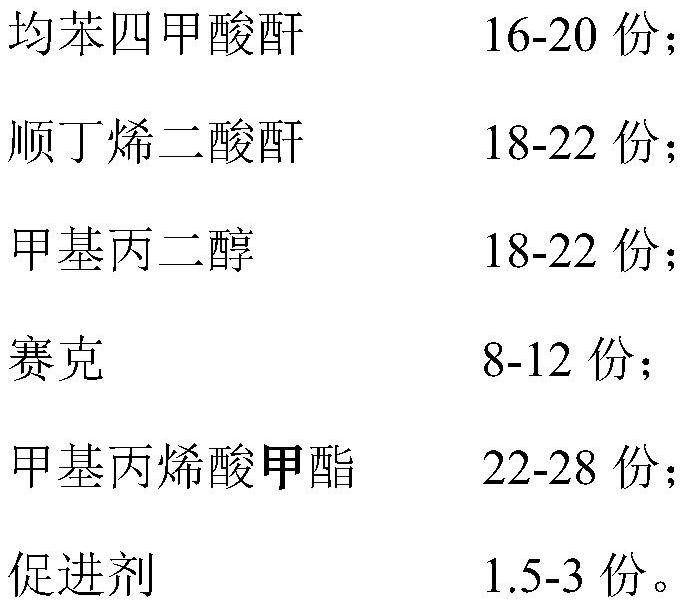

[0030] The composition of the raw materials for the preparation of the insulating resin (0840-D) in this example is as follows (parts by weight):

[0031]

[0032] The preparation process of the insulating resin (0840-D) is:

[0033] (1) After feeding nitrogen in the reaction vessel, drop into pyromellitic anhydride, maleic anhydride, methylpropanediol and Cyclo in proportion successively;

[0034] (2) Heating the mixed material after feeding in the reaction vessel in step (1), heating to 160-175°C to start the esterification reaction, and then gradually warming up to 200-210°C for heat preservation reaction;

[0035] (3) During the heat preservation reaction in step (2), when the acid value reaches 30 mgKOH / g, cool down to below 130° C., then add methyl methacrylate and accelerator (cobalt acetylacetonate (Ⅲ)) to the reaction vessel and Mix evenly and obtain component A after filling;

[0036] (4) Mix component A and component B (dicumyl peroxide DCP) in a weight ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com