Binder-free preparation method for preparing composite carbon-based fertilizer by using biogas residues

A technology of compound carbon and biochar base fertilizer, applied in urea compound fertilizer, application, potash fertilizer and other directions, can solve the problems of non-binder biochar base fertilizer not easy to form, low utilization rate of chemical fertilizer, low hardness, etc. Sustained development, lower production cost, good compression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

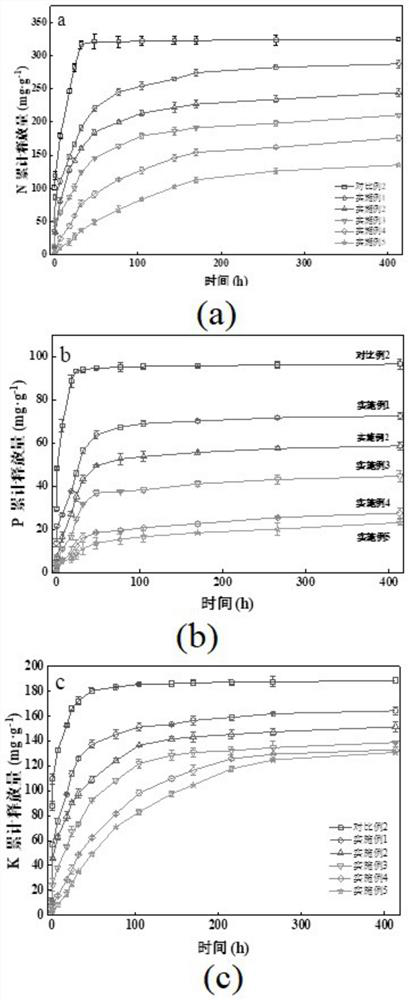

[0044] Embodiment 1-5 adopts the preparation method as described below to prepare:

[0045] Pretreatment: Collect biogas residue after solid-liquid separation, air-dry and pulverize to obtain dry biogas residue powder;

[0046] High-temperature pyrolysis: transfer the dried biogas residue powder obtained from pretreatment into a muffle furnace, and perform pyrolysis for a period of time under the conditions of pyrolysis temperature to obtain biogas residue biochar materials;

[0047] Preparation of biogas residue carbon-based compound fertilizer: The biogas residue biochar material obtained by high-temperature pyrolysis is uniformly mixed with urea, diammonium hydrogen phosphate, potassium chloride and distilled water in a certain proportion to prepare a composite biogas residue biochar-based fertilizer.

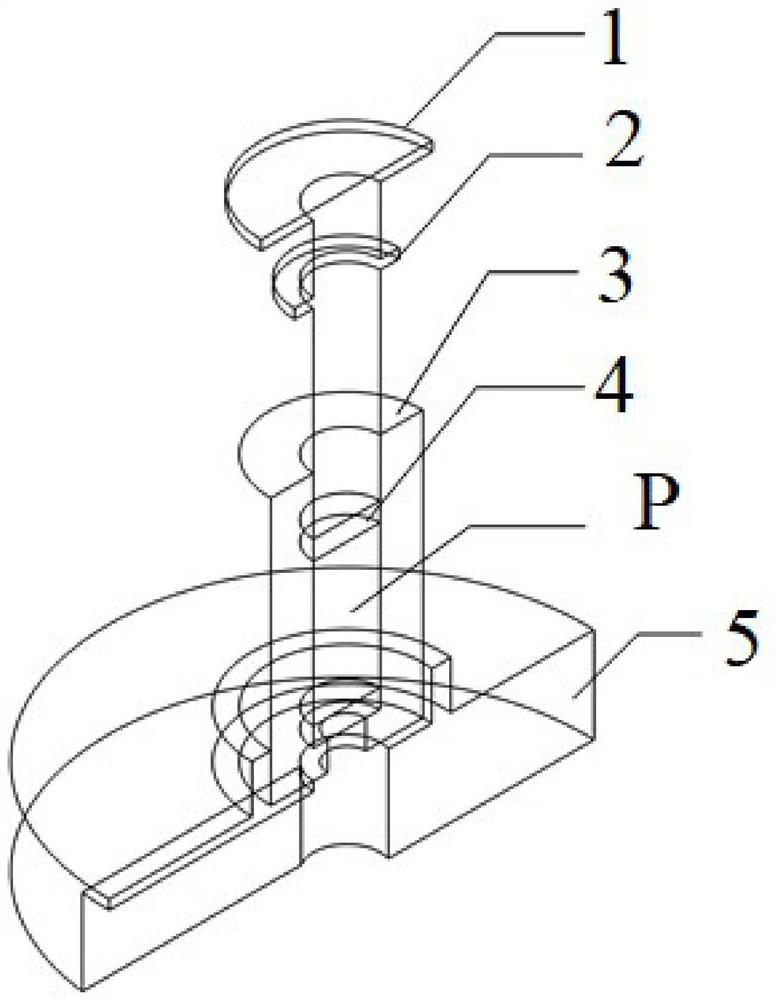

[0048] Granulation preparation: the prepared composite biochar residue biochar-based fertilizer is placed in an extrusion granulator, and granulated under certain compressio...

Embodiment 1

[0062] Biogas residue carbon-based compound fertilizer: 35 parts of biogas residue biochar, 28 parts of urea, 20 parts of diammonium hydrogen phosphate, 20 parts of potassium chloride, 7.5 parts of distilled water, and uniformly mixed to prepare a composite biogas residue biochar-based fertilizer.

[0063] Granulation preparation: put the prepared biogas residue carbon-based compound fertilizer in an extrusion granulator with a sleeve diameter of 7mm, and granulate under the conditions of a compression speed of 50mm / min and a pressure of 7.5Mpa to obtain a granular form Composite biochar residue biochar fertilizer.

[0064] Granular drying: The prepared granular composite biochar-based fertilizer was dried at 25°C for 8 hours.

Embodiment 2

[0066] Biogas residue carbon-based compound fertilizer: 40 parts of biogas residue biochar, 30 parts of urea, 22 parts of diammonium hydrogen phosphate, 22 parts of potassium chloride, 5 parts of distilled water, and uniformly mixed to prepare a composite biogas residue biochar-based fertilizer.

[0067] Granulation preparation: put the prepared biogas residue carbon-based compound fertilizer in an extrusion granulator with a sleeve diameter of 7mm, and granulate under the conditions of a compression speed of 60mm / min and a pressure of 7.5Mpa to obtain a granule Composite biochar residue biochar fertilizer.

[0068] Granular drying: The prepared granular composite biochar-based fertilizer was dried at 65°C for 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com