A metal nanoframe with an array structure and its preparation method and application

A metal nano and array structure technology, applied in metal processing equipment, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of not fully utilizing plasmonic metals, restricting large-scale application of nanostructures, Complex structural synthesis and other issues, to achieve the effect of enriching catalytic active sites, good plasmon effect, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The metal nanoframe has a purity of 99% and an absorbance of 2. The preparation method of metal nano frame solution comprises the following steps:

[0029] (1) Add 1 mL of gold nano-bipyramid 1 solution to 10 mL, 0.08 mol / L cetyltrimethylammonium chloride solution, and then add 125 μL, 0.1 mol / L ascorbic acid solution and 250 μL, 0.01 mol / L ascorbic acid solution to it. L AgNO 3 solution, shake the mixed solution evenly, put it in an oven at 60°C, and react for 5 hours to obtain silver nanorods;

[0030] (2) Centrifuge the silver nanorods obtained in step (1) at 5000rpm for 10min, then disperse them in 4mL, 0.05mol / L cetyltrimethylammonium bromide solution, add 1mL, 0.1mol / L L of ascorbic acid solution and 1mL, 0.2mol / L NaOH solution, at room temperature, slowly add 1.6mL, 0.1mmol / L chloropalladium acid reaction solution dropwise at a rate of 20μL / min, and react for 2h;

[0031] (3) Centrifuge the sample obtained in step (2) at 6000rpm for 10min, then disperse it int...

Embodiment 1

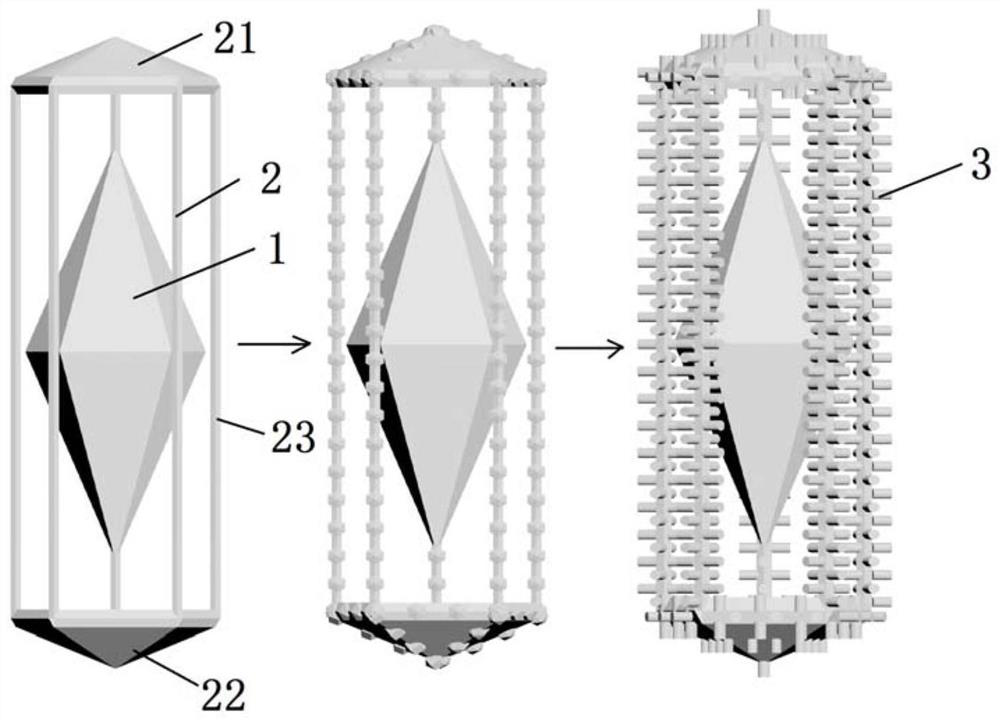

[0034] Such as figure 1 , a method for preparing a metal nanoframe of an array structure 3, comprising the following steps:

[0035] (a) Add 1mL metal nanoframe solution to 10mL, 10mmol / L surfactant cetylpyridinium chloride solution, then add 90μL, 1mmol / L chloropalladium acid solution and 90μL, 10mmol / L ascorbic acid solution;

[0036] (b) Shake the solution obtained in step a, and react in an oven at 65° C. for 0.5 h to obtain the metal nanoframe of palladium array structure 3 .

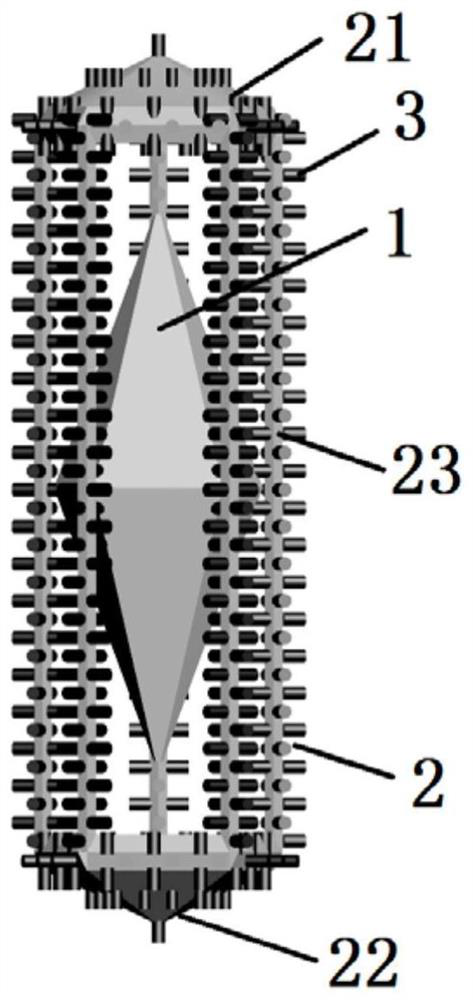

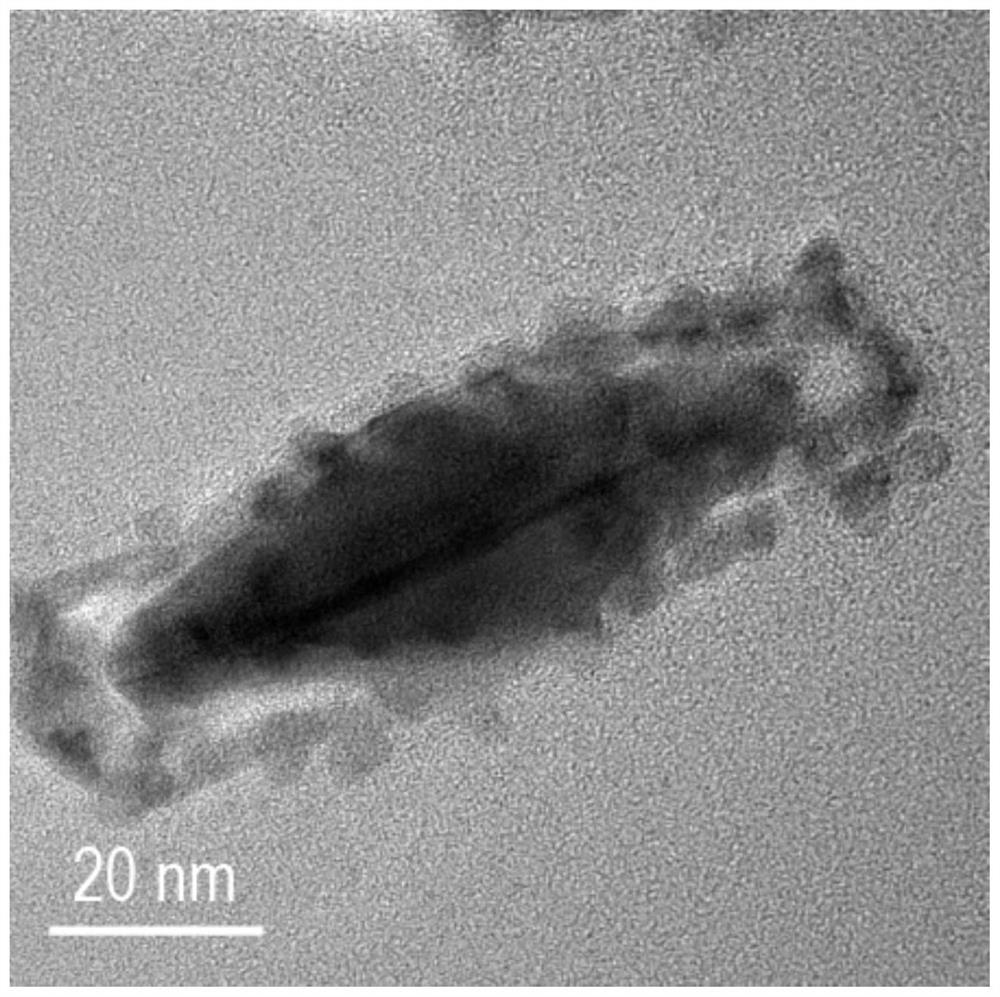

[0037] Such as figure 2 , the metal nano frame that the present embodiment makes comprises gold nano bicone 1 and outer layer frame body 2, and outer layer frame body 2 is the gold-silver alloy that is made up of silver atom and gold atom, and evenly distributes palladium on the outer layer frame body 2 Array structure3. Outer layer frame body 2 comprises point one 21, point two 22 and connecting rod 23, and point one 21, point two 22 are regular pentagonal pyramids and are arranged symmetrical...

Embodiment 2

[0041] A method for preparing a metal nanoframe of an array structure 3, comprising the following steps:

[0042] (a) Add 1mL metal nanoframe solution to 10mL, 1mmol / L surfactant cetylpyridinium chloride solution, then add 90μL, 5mmol / L chloroplatinic acid solution and 90μL, 30mmol / L ascorbic acid solution;

[0043] (b) Shake the solution obtained in step a, and react in an oven at 30° C. for 17 hours to obtain the metal nanoframe of the platinum array structure 3 .

[0044]The metal nanoframe prepared in this embodiment includes a gold nanobicone 1 and an outer frame 2, the outer frame 2 is a gold-silver alloy, and a single platinum array structure 3 with a length of 5 nm is evenly distributed on the outer frame 2 . Outer layer frame body 2 comprises point one 21, point two 22 and connecting rod 23, and point one 21, point two 22 are regular pentagonal pyramids and are arranged symmetrically about connecting rod 23, and connecting rod 23 is connected with point one respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com