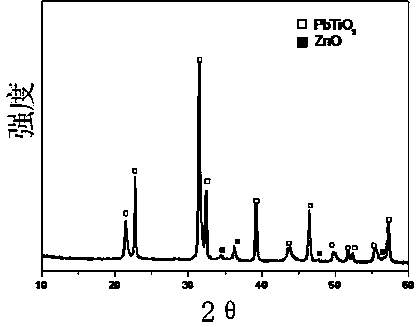

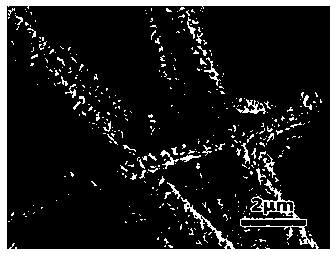

Preparation method of lead titanate/zinc oxide composite nanostructure on flexible substrate

A composite nanostructure and flexible substrate technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as no related reports, and achieve the effects of simple process, good dispersion and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Configure Pb 2+ 20ml of lead nitrate aqueous solution with an ion concentration of 0.25mol / L; dissolving butyl titanate in ethylene glycol methyl ether to make the Ti in the solution 4+ The ion concentration is 0.25mol / L, add ammonia water with a mass concentration of 30% to Ti 4+ Ions are completely precipitated, filtered, washed, and titanium hydroxide precipitates are obtained;

[0021] 2) Prepare 20ml of 1mol / L potassium hydroxide aqueous solution and 40ml of 2g / L polyvinyl alcohol aqueous solution respectively, and combine potassium hydroxide aqueous solution, polyvinyl alcohol aqueous solution, titanium oxyhydroxide precipitation and step 1) lead nitrate aqueous solution together Added to the inner tank of the reactor, Ti 4+ Pb in lead nitrate solution 2+ The molar ratio is 1:1, placed in the reactor, airtight, at 180 o Insulation in the furnace of C, after reacting for 12 hours, be placed in the air and naturally cool down to room temperature, take out the...

Embodiment 2

[0028] 1) Configure Pb 2+ 20ml of lead nitrate aqueous solution with an ion concentration of 0.5mol / L; dissolving butyl titanate in ethylene glycol methyl ether to make the Ti in the solution 4+ Concentration is 0.5mol / L, add the ammoniacal liquor of mass concentration 30% to Ti 4+ The ions are completely precipitated, filtered and washed to obtain the precipitated titanium oxyhydroxide;

[0029]2) Prepare 20ml of 0.5mol / L potassium hydroxide aqueous solution and 40ml of 2g / L polyvinyl alcohol aqueous solution respectively, and deposit potassium hydroxide aqueous solution, polyvinyl alcohol aqueous solution, titanium hydroxide solution and lead nitrate aqueous solution in step 1) Together into the reactor liner, Ti 4+ Pb in lead nitrate solution 2+ The molar ratio is 1:1, placed in the reactor, airtight, at 200 o Insulate in the furnace of C, after reacting for 12 hours, place in the air and naturally cool down to room temperature, take out the reaction product, filter, wa...

Embodiment 3

[0035] 1) Configure Pb 2+ 20ml of lead nitrate aqueous solution with an ion concentration of 1mol / L; dissolving butyl titanate in ethylene glycol methyl ether to make Ti in the solution 4+ The concentration is 1mol / L, add ammonia water with a mass concentration of 30% to Ti 4+ The ions are completely precipitated, filtered and washed to obtain the precipitated titanium oxyhydroxide;

[0036] 2) Prepare 20ml of 2mol / L potassium hydroxide aqueous solution and 40ml of 2g / L polyvinyl alcohol aqueous solution respectively, and combine potassium hydroxide aqueous solution, polyvinyl alcohol aqueous solution, titanium oxyhydroxide precipitation and step 1) lead nitrate aqueous solution together Added to the inner tank of the reactor, Ti 4+ Pb in lead nitrate solution 2+ The molar ratio is 1:1, placed in the reactor, airtight, at 200 o Insulate in the furnace of C, after reacting for 10 hours, place in the air and naturally cool down to room temperature, take out the reaction prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com