Clutch type treatment process for textile waste gas

A treatment process, a clutch-type technology, applied in the field of textile waste gas clutch-type treatment process, can solve the problems of accelerating the speed of filter clogging, affecting the efficiency of textile waste gas emission, clogging of filter plates, etc., to achieve accelerated permeability, accelerated recovery, The effect of permeability recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

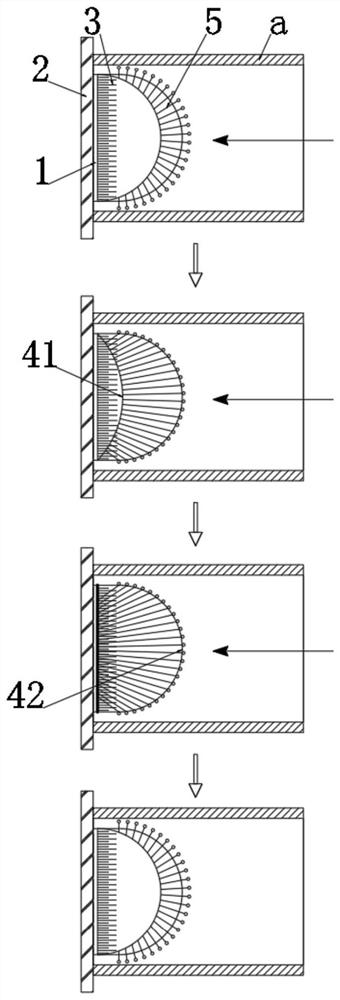

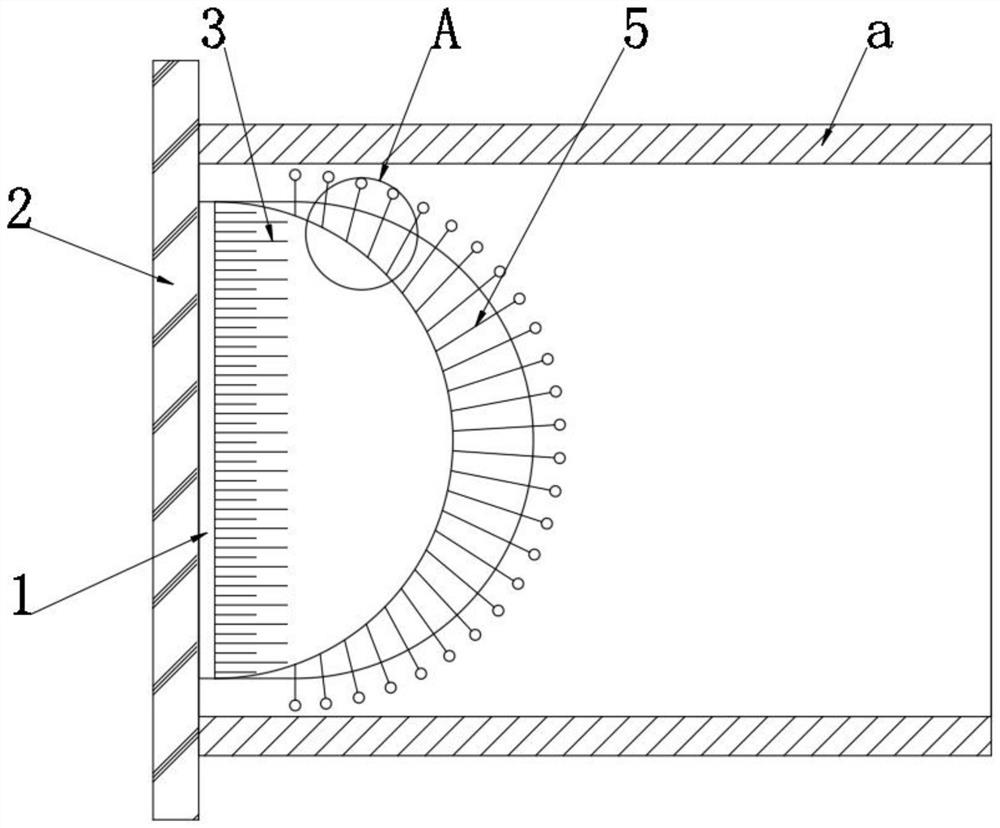

[0049] see figure 1 , a in the figure represents the exhaust pipe, a textile waste gas clutch type treatment process, including the following steps:

[0050] S1. First, connect the double-layer dynamic filter pocket to the exhaust pipe with threads;

[0051] S2. Lead the exhaust gas into the exhaust pipe, so that the exhaust gas passes through the double-layer dynamic filter bag, so as to intercept the fiber impurities in the exhaust gas;

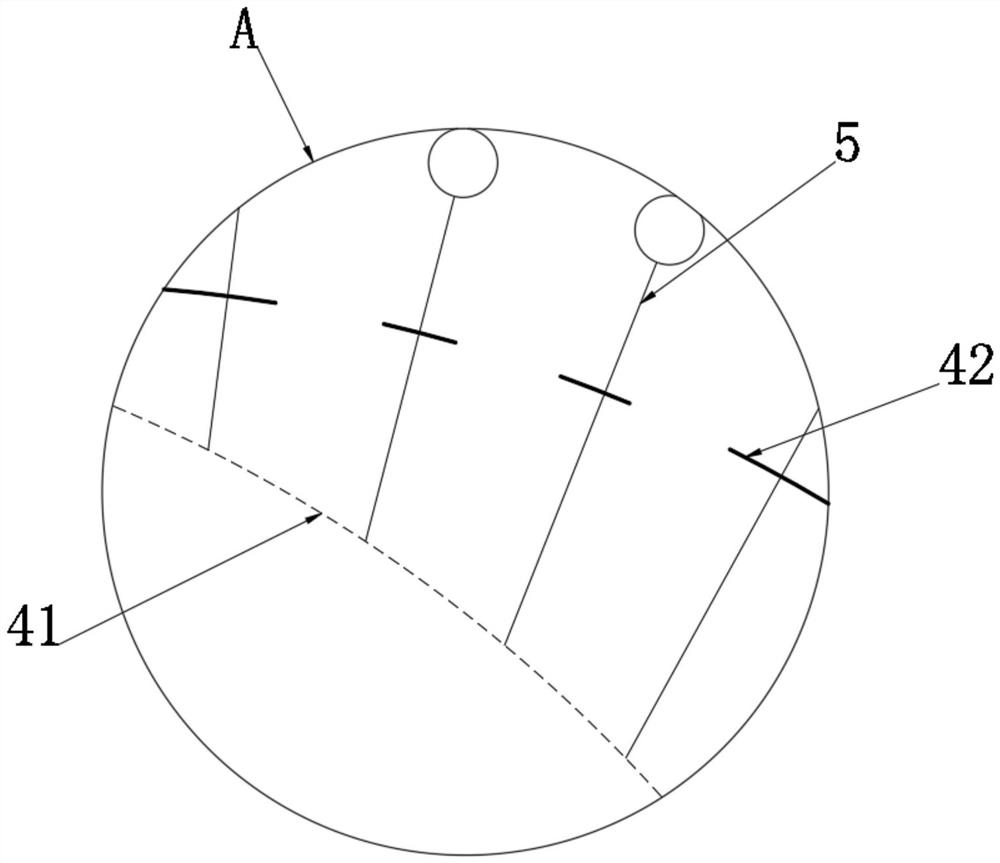

[0052] S3. With the prolongation of exhaust gas treatment time, the permeability of the double-layer dynamic filter bag becomes worse. Under the impact of exhaust gas, the inner layer net bag 41 gradually moves along the direction of exhaust gas running, and is separated from the outer layer net bag 42, making the soft The soft insertion rod 5 of the insertion rod moves on the outer net bag 42, effectively loosening the impurities intercepted on the outer net bag 42;

[0053] S4, continue to feed exhaust gas, push the inner layer net bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com