A kind of preparation method of camellia oil crude oil and tea soap organic liquid

A technology of camellia and oil hair, applied in the direction of biochemical equipment and methods, edible oil/fat, microorganisms, etc., can solve the problems of increasing the content of benzo hazards, solvent residues, increasing production costs, etc., and achieves a simple and easy-to-operate preparation method , save production cost and time, overcome the effect of complex processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

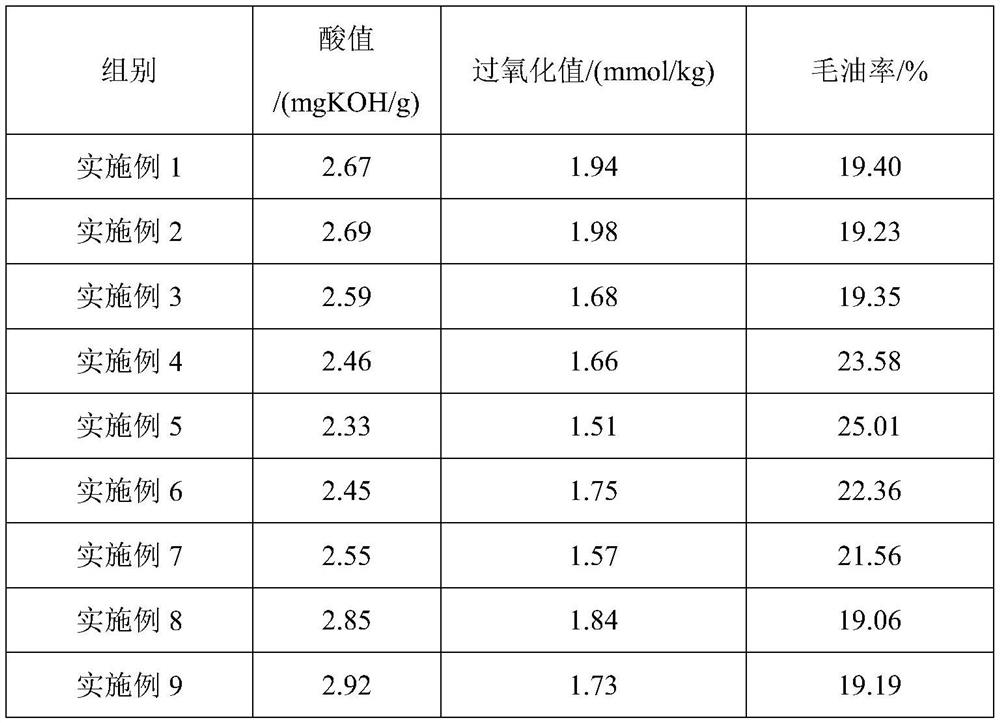

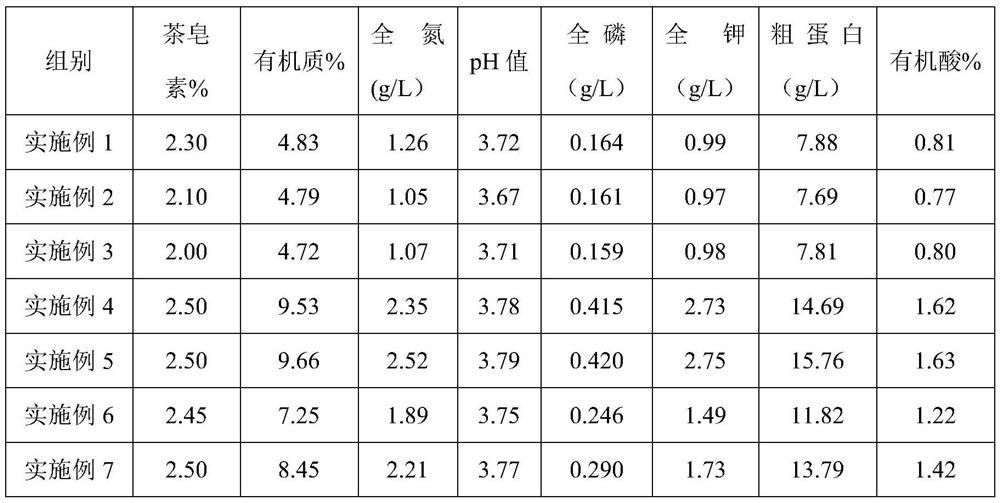

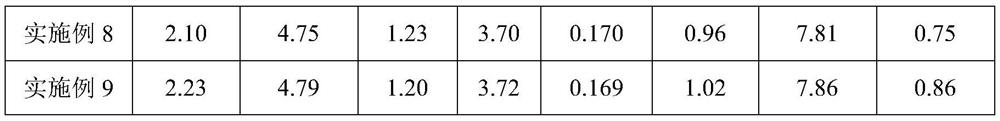

Examples

Embodiment 1

[0027] The preparation of camellia oil crude oil and tea soap organic liquid comprises the following steps:

[0028] (1) after drying the picked camellia seeds at low temperature (35°C), after storing at 0°C for 14 days, husk them to obtain camellia seed kernels; the obtained camellia seed kernels are put into a beating machine and pulverized;

[0029] (2) putting the pulverized camellia seed kernels in step (1) into 30 ° C warm water and soaking, wherein the weight ratio of the camellia seed kernels and warm water is 1: 4, after soaking for 1h, grind into slurries less than 100 meshes with a stone mill;

[0030] (3) filter the obtained slurry in step (2) with a 120-mesh filter cloth, then wash the slurry twice with normal temperature water, and the obtained filter residue is used as camellia cake feed, with a moisture content of 4.8wt% and a crude fat content of 15.1wt% , the crude protein content is 8.08wt%, the crude ash content is 2.7wt%, and the crude fiber content is 18....

Embodiment 2

[0034] The preparation of camellia oil crude oil, the steps are as follows:

[0035] (1) after the plucked camellia seeds are dried at low temperature, stored at 8°C for 320 days, shelled to obtain camellia seed kernels; the obtained camellia seed kernels are put into a beating machine and pulverized;

[0036] (2) Put the pulverized camellia seed kernels in step (1) into warm water at 25°C for soaking, wherein the weight ratio of the camellia seed kernels to the warm water is 1:3.5, after soaking for 1.5h, grind it into a slurry of less than 100 meshes with a stone mill ;

[0037] (3) filter the obtained slurry in step (2) with a 120-mesh filter cloth, then wash the slurry twice with normal temperature water, and the obtained filter residue is used as camellia cake feed, with a moisture content of 4.5wt% and a crude fat content of 16.0wt% , the crude protein content was 8.2 wt%, the crude ash content was 2.6 wt%, and the crude fiber content was 18.1 wt%. The obtained filtrate...

Embodiment 3

[0040] The preparation of camellia oil crude oil includes the following steps:

[0041] (1) after the plucked camellia seeds are dried at low temperature, stored at normal temperature (25° C.) for 320 days, shelled to obtain camellia seed kernels; the obtained camellia seed kernels are put into a beater and pulverized;

[0042] (2) putting the pulverized camellia seed kernel in step (1) into 35 ℃ of warm water and soaking, wherein the weight ratio of camellia seed kernel and warm water is 1: 4.5, after soaking for 1h, grind to be less than 100 mesh slurries with a stone mill;

[0043](3) filter the obtained slurry in step (2) with a 120-mesh filter cloth, then wash the slurry twice with normal temperature water, and the obtained filter residue is used as camellia cake feed, with a moisture content of 3.8wt% and a crude fat content of 15.9wt% , the crude protein content was 7.95wt%, the crude ash content was 2.1wt%, and the crude fiber content was 17.8wt%. The obtained filtrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com