Capacitive online monitoring product and method of mixed continuous fiber composite material

A fiber composite material, mixed continuous technology, applied in the direction of material capacitance, material analysis, material analysis through electromagnetic means, etc., can solve the problems of reducing the mechanical properties of components, affecting the mechanical properties of components, and the inability to achieve high-precision monitoring, etc., to achieve stability Mechanical properties, the effect of not reducing the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

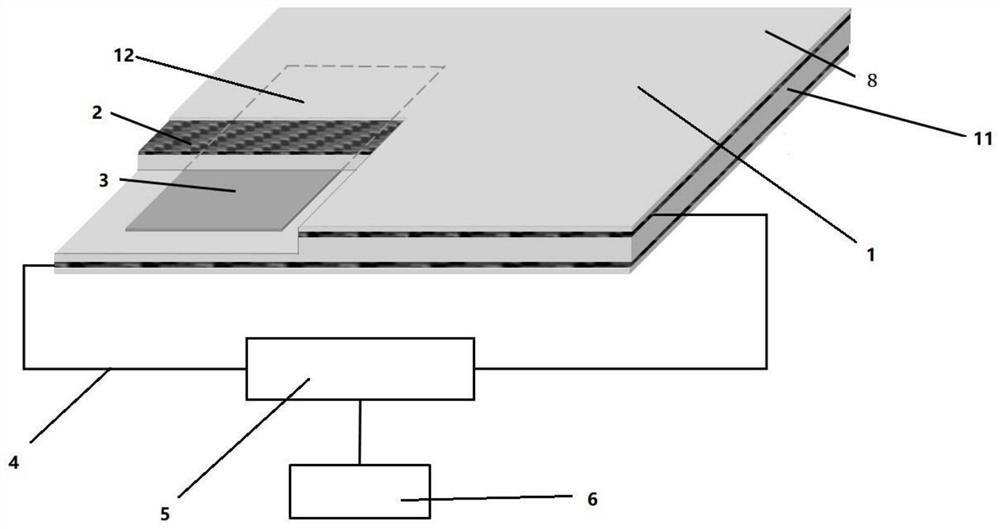

[0053] Such as figure 1 As shown, the present embodiment provides a capacitive on-line monitoring product of mixed continuous fiber composite material. Fiber composite material layer 1, polymer film 3 and conductive continuous fiber composite material layer 2;

[0054] The non-conductive continuous fibers of the non-conductive continuous fiber composite material layer 1 include glass fiber, aramid fiber, basalt fiber, ultra-high molecular weight polyethylene fiber, and also include a specific layer 11, and a specific area 12 is arranged on the specific layer 11, and the specific area A polymer film 3 is arranged inside 12, and a conductive continuous fiber composite material layer 2 is arranged on the upper surface and the lower surface of the specific layer 11;

[0055] The polymer film 3 is a high dielectric flexible polymer film, which includes polyvinylidene fluoride (PVDF) and its copolymers, nylon, polyamide-imide, polyvinyl chloride, polyvinylidene chloride Ethylene, ...

Embodiment 2

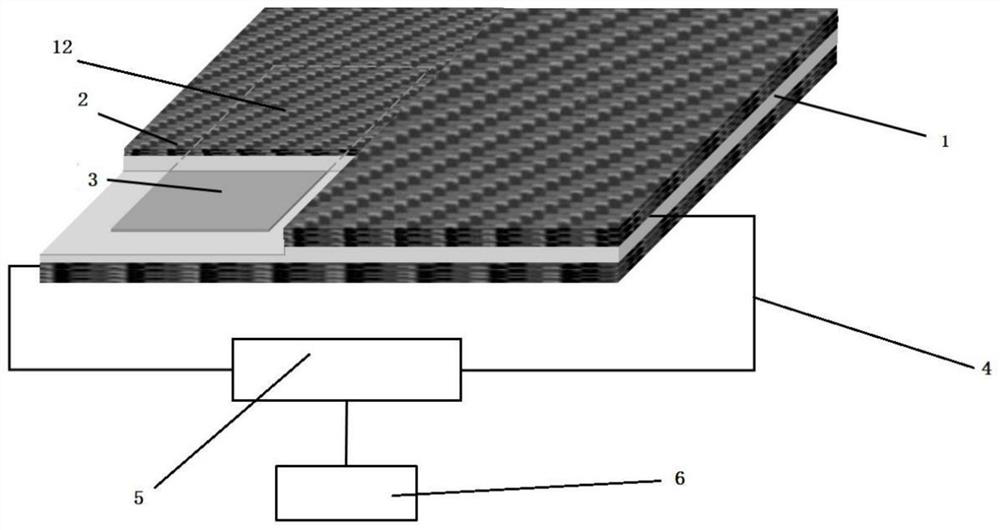

[0086] Such as figure 2 As shown, the present embodiment provides a capacitive on-line monitoring product of a mixed continuous fiber composite material. Composite material layer 1, polymer film 3 and conductive continuous fiber composite material layer 2;

[0087]The non-conductive continuous fibers of the non-conductive continuous fiber composite material layer 1 include glass fiber, aramid fiber, basalt fiber, ultra-high molecular weight polyethylene fiber, and the non-conductive continuous fiber composite material layer is used as a specific layer 11, and a specific layer 11 is arranged on the specific layer 11. Area 12, the polymer film 3 is arranged in the specific area 12, and the conductive continuous fiber composite material layer 2 is arranged on the upper surface and the lower surface of the specific layer 11;

[0088] The polymer film 3 is a high dielectric flexible polymer film, which includes polyvinylidene fluoride (PVDF) and its copolymers, nylon, polyamide-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com