Method for depositing diamond-like carbon film on surface of inner wall of metal cylinder (or tube) with large length-diameter ratio

A technology of diamond thin film and large aspect ratio, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the difficulty of reaction gas transportation, difficult deposition of DLC diamond-like film material, and difficulty in plasma formation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

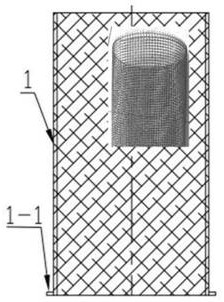

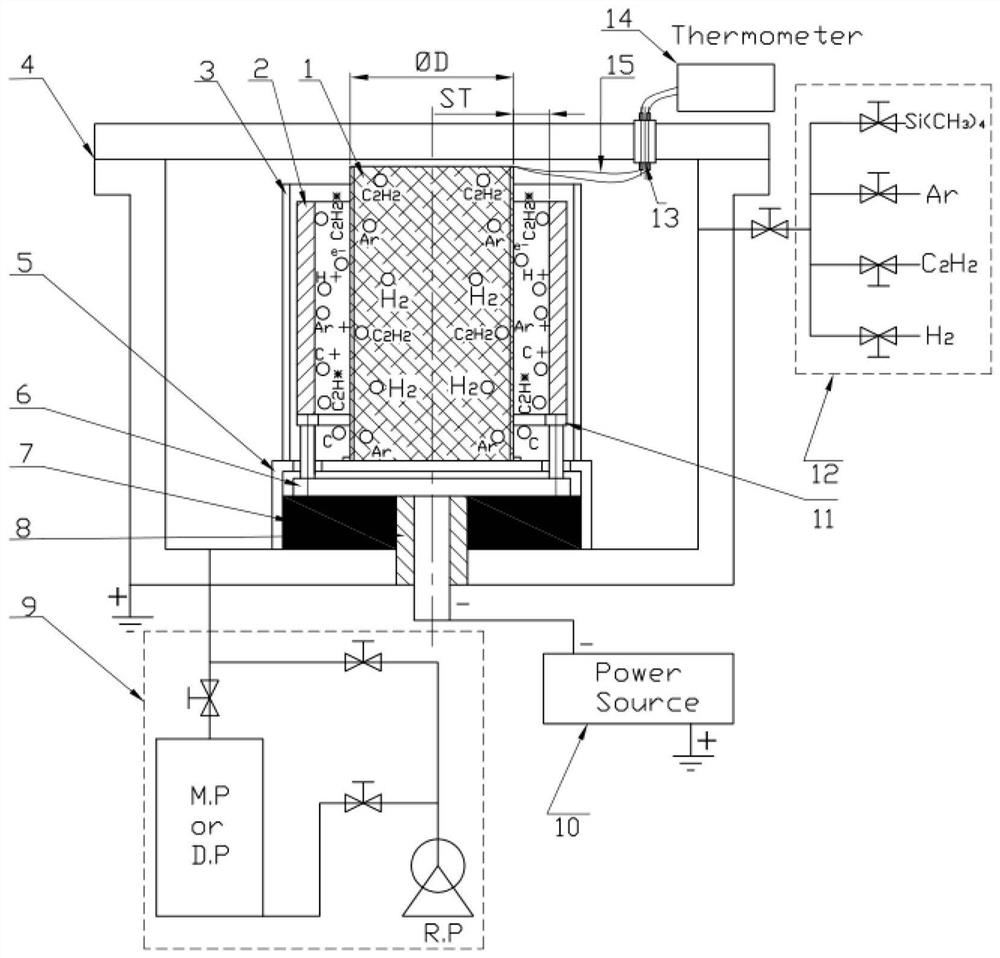

[0034] see figure 1 and figure 2 Embodiment 1 of the present invention provides a method for depositing a DLC diamond-like carbon film material on the inner wall surface of a metal cylinder (or tube) with a large aspect ratio. The detailed steps of the method are as follows:

[0035] a. First, polish the inner wall of the metal-plated cylinder (or tube) 2 to make the surface roughness reach Ra0.8, then put it into an ultrasonic cleaning tank, clean it with acetone for 10 minutes, and blow it dry with clean dry air after taking it out;

[0036] b, the wire mesh anode cylinder 1 is fixed on the anode cover 5, the metal-plated cylinder (or tube) 2 is placed on the conductive ring 11, and the anode is installed on the periphery of the metal-plated cylinder (or tube) 2 and the conductive ring 11 cylinder 3, and fix the anode cylinder 3 on the anode cover 5, connect the thermocouple 15 to the upper end of the screen anode cylinder 1, and connect the thermocouple 15 to the vacuum e...

Embodiment 2

[0041] Embodiment two: basically the same as embodiment one, the difference is:

[0042] In this example, the distance between the anode cover 5 and the conductive ring 11 is 30mm, and the distance from the top end of the metallized cylinder 2 to the anode cover 5 is 135mm, so the total length of the screen anode cylinder 1 made is 165mm . The diameter of the inner wall of the metal-plated cylinder 2 is Φ80mm, and the inner wall of the metal-plated cylinder 2 is spaced 15mm from the outer circumference of the wire mesh anode cylinder 1, so the wire mesh anode cylinder 1 is a hollow wire mesh cylinder with an outer diameter of Φ50mm.

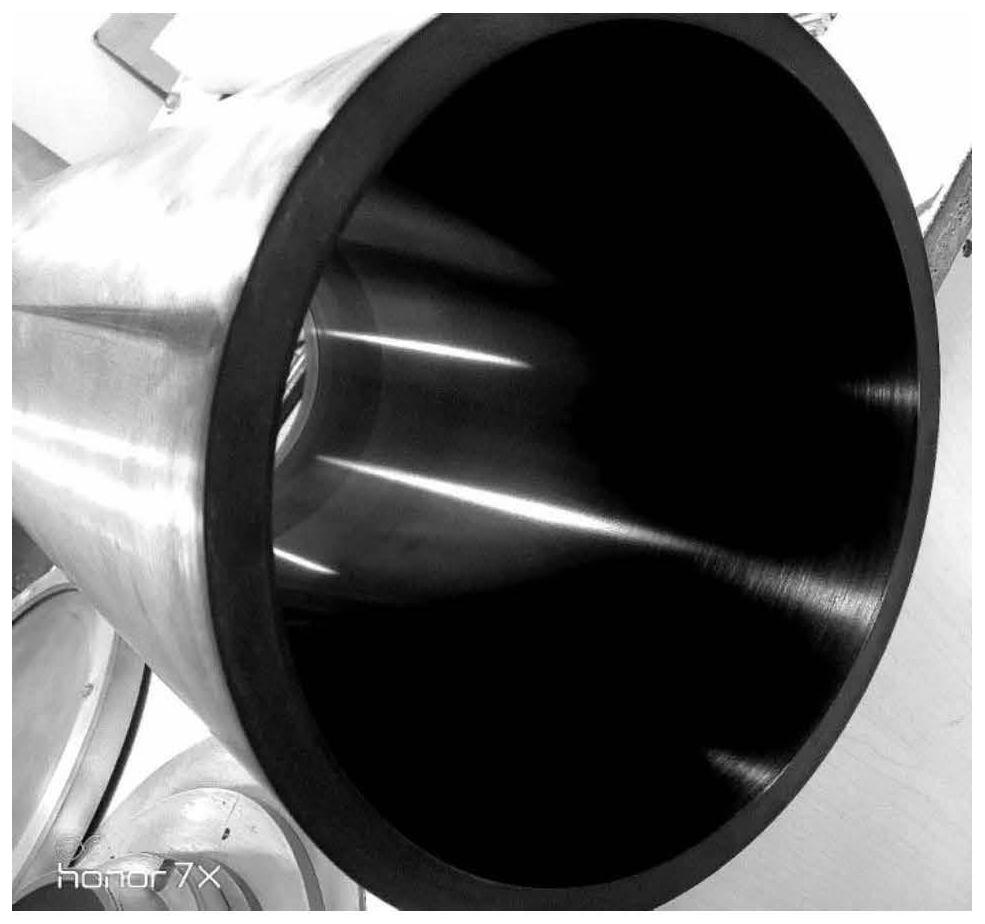

[0043] The resulting product is attached Figure 6 , 7 Among them, the inner wall of the SUS304 stainless steel cylinder with an inner diameter of 80mm and a length of 100mm has obtained a continuous surface diamond-like film with high interface strength. The film deposition is black, and the surface is smooth and dense. in the attached Figu...

Embodiment 3

[0044] Embodiment three: basically the same as embodiment one, the difference is:

[0045] In this example, the distance between the anode cover 5 and the conductive ring 11 is 30mm, and the distance from the top end of the metallized cylinder 2 to the anode cover 5 is 640mm, so the total length of the screen anode cylinder 1 made is 670mm . The diameter of the inner wall of the metal-plated cylinder 2 is Φ150mm, and the inner wall of the metal-plated cylinder 2 is spaced 20mm from the outer circumference of the wire mesh anode cylinder 1, so the wire mesh anode cylinder 1 is a hollow wire mesh cylinder with an outer diameter of Φ110mm.

[0046] The resulting product is attached Figure 9 , 10 Among them, the inner wall of the ductile iron cylinder with an inner diameter of 150mm and a length of 600mm has obtained a continuous surface diamond-like film with high interface strength. The film deposition is black, and the surface is smooth and dense. in the attached Figure 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com