Ce-Mn-based solid solution catalyst and preparation method and application thereof

A solid solution, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as high energy consumption, unfavorable large-scale application, and rising catalyst preparation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a preparation method of a Ce-Mn-based solid solution catalyst, comprising the following steps:

[0035] Mixing the mixed solution of soluble cerium salt and potassium permanganate with soluble manganese salt, adjusting the pH value to be greater than 7, performing redox reaction and aging in sequence, and calcining the obtained solid to obtain the Ce-Mn-based solid solution catalyst;

[0036] The holding temperature of the calcination is 400-600°C, and the time is <8h.

[0037] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0038] In the present invention, the mixed solution of soluble cerium salt and potassium permanganate is mixed with soluble manganese salt, the pH is adjusted to be alkaline, and after redox reaction and aging are carried out in sequence, the obtained solid is calcined to obtain the Ce-Mn-based solid solution cataly...

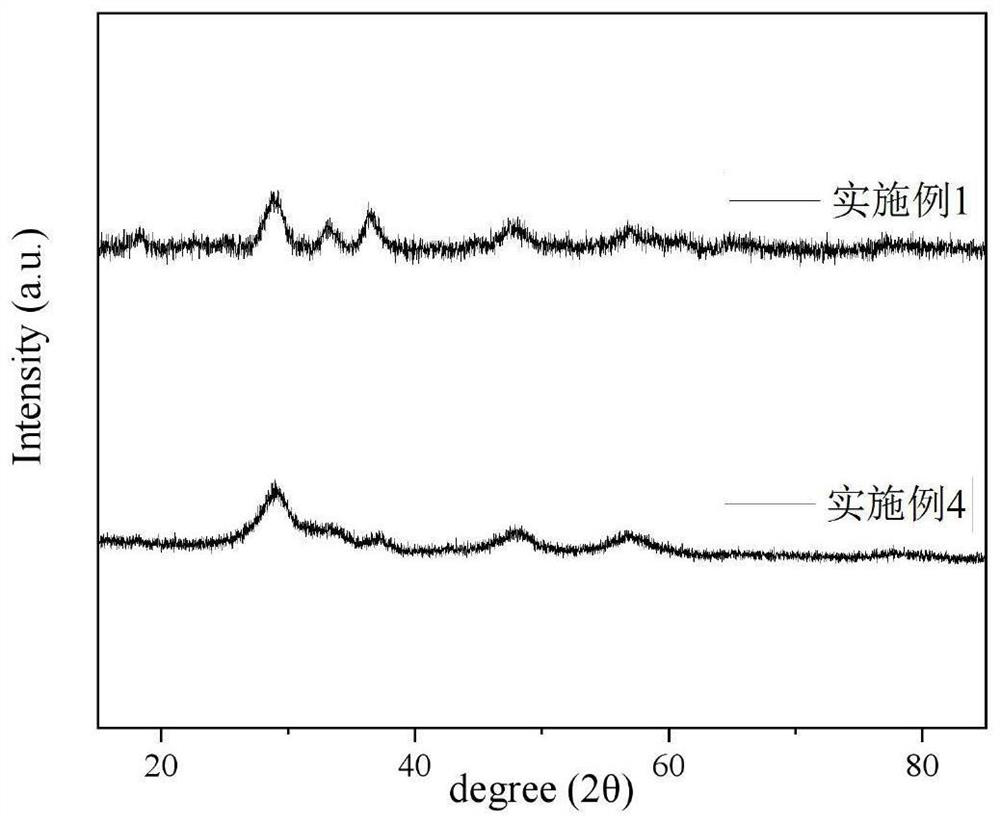

Embodiment 1

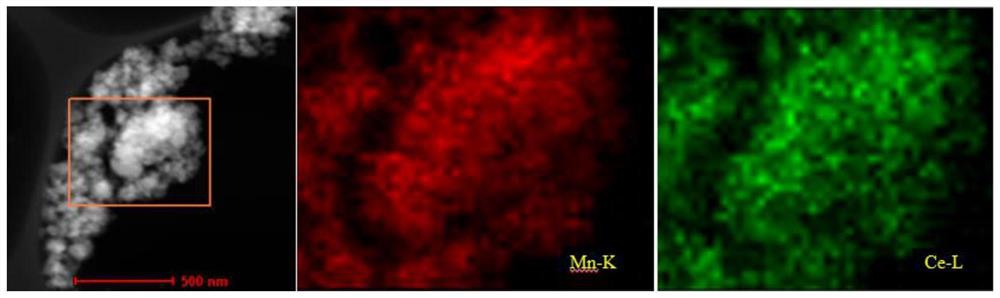

[0074] Under stirring conditions, at 50 °C, 50 mL of cerium nitrate solution with a concentration of 0.2 mol / L and 70 mL of potassium permanganate solution with a concentration of 0.02 mol / L were mixed and stirred for 10 min, and then 1.40 mL of a mass concentration of 50 was added dropwise. % manganese nitrate (0.006mol), after stirring for 5min, quickly add 20mL of cobalt nitrate solution with a concentration of 0.25mol / L to it, adjust the pH value to 10.5 with 0.8mol / L potassium hydroxide solution, stir for 2h, age 2h, filter and wash to neutrality in sequence; dry at 110°C for 12h, then calcinate at 400°C for 6h in an air atmosphere with a heating rate of 2°C / min to obtain the Ce-Mn-based solid solution catalyst (with a specific surface area of 105 m 2 / g, the average pore size is 14nm, the molar ratio of cerium element, manganese element and copper element is 2:4:1, Mn 3+ The molar ratio to manganese is 0.65, Ce 3+ The molar ratio of cerium and cerium is 0.15, O ads / ...

Embodiment 2

[0076] Under stirring conditions, at 60 ° C, 30 mL of cerium nitrate solution with a concentration of 0.33 mol / L and 90 mL of potassium permanganate solution with a concentration of 0.044 mol / L were mixed and stirred for 5 minutes, and then 1.40 mL of a mass concentration of 50 was added dropwise. % manganese nitrate, after stirring for 10min, adjust the pH value to 9 with 2mol / L potassium hydroxide solution, stir for 2.5h, age for 2h, filter and wash to neutrality in sequence; In the atmosphere, calcined at 400 °C for 6 h (firstly increased to 200 °C at a heating rate of 5 °C / min, and then increased to 400 °C at a heating rate of 2 °C / min) to obtain the Ce-Mn-based solid solution catalyst (specific surface area: 133m 2 / g, the average pore size is 11nm, the molar ratio of cerium and manganese is 1:1, Mn 3+ The molar ratio to manganese is 0.65, Ce 3+ The molar ratio of cerium and cerium is 0.15, O ads / O latt is 0.53).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com