Novel high-flux positively charged nanofiltration membrane and preparation method thereof

A positively charged, high-flux technology, applied in the field of membrane separation, can solve the problems of positively charged nanofiltration membrane preparation time and low water flux, and achieve the effects of low preparation cost, stable performance, and increased porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

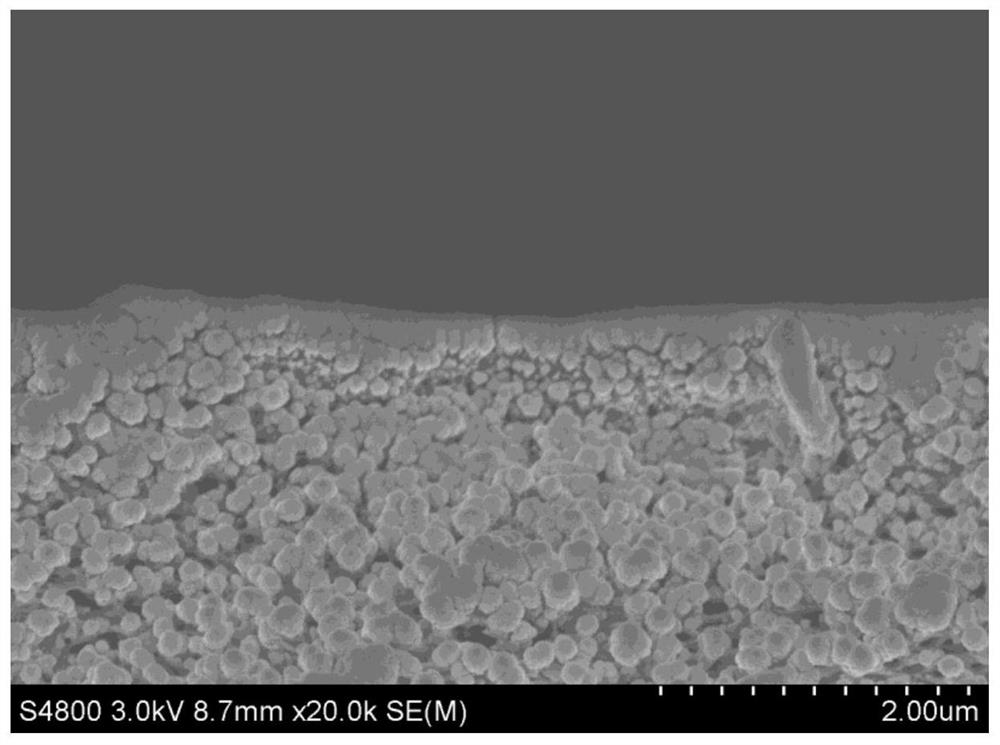

Image

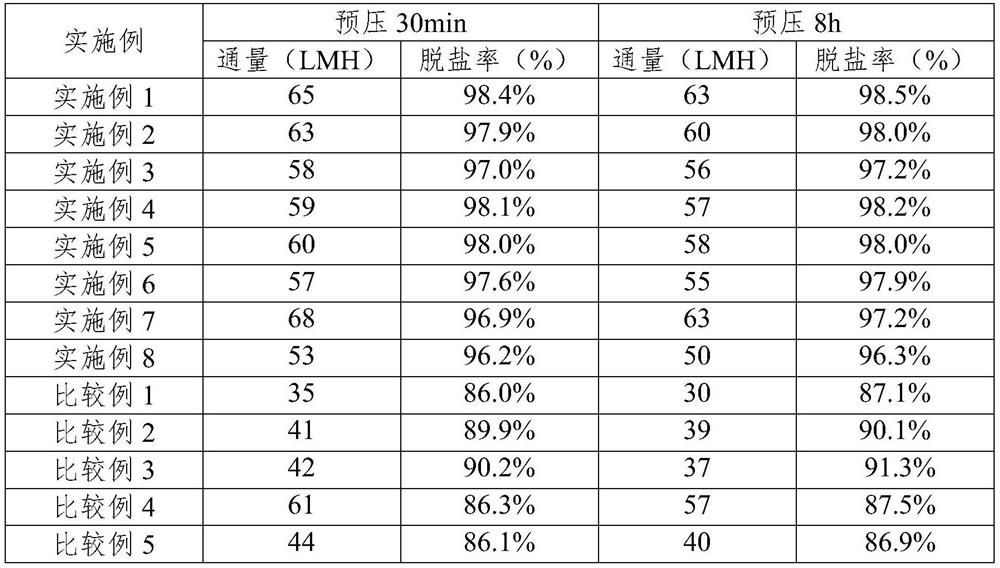

Examples

preparation example Construction

[0051] The novel high-flux positively charged nanofiltration membrane of the present invention is obtained by a novel high-flux positively charged nanofiltration membrane preparation method, the preparation method comprising the following steps:

[0052] S1: Prepare the aqueous phase solution: add surfactant and proton acceptor to the aqueous solution containing the hydrophilic group polyamine monomer, mix well; the hydrophilic group polyamine monomer is 2,4-diamino -6-phenyl-1,3,5-triazine, 1,3-bis(aminomethyl)cyclohexane, tris(hydroxymethyl)aminomethane, N-aminophthalimide and 2, At least one of 4-dimethoxybenzylamine; the mass concentration of the hydrophilic polyamine monomer in the aqueous phase solution is 0.5%-5%; the mass concentration of the proton accepting agent in the aqueous phase solution is 1 %-5%; the mass concentration of the surfactant in the aqueous phase solution is 0.1%-5%; preferably 0.1%-3%;

[0053] S2: Immerse the porous support layer in the water pha...

Embodiment 1

[0061] A novel high-flux positively charged nanofiltration membrane preparation method:

[0062] S1: Configure the aqueous phase solution: add trisodium phosphate and sodium lauryl sulfate to the aqueous solution of N-aminophthalimide, and mix well; N-aminophthalimide in the aqueous phase solution The mass concentration of trisodium phosphate is 0.5%, the mass concentration of trisodium phosphate is 3%, and the mass concentration of sodium lauryl sulfate is 3%;

[0063] S2: Immerse the porous support ultrafiltration bottom membrane in the water phase solution of S1 for 60s, remove the excess water phase solution on the surface of the porous support ultrafiltration bottom membrane with a roller; then immerse the porous support layer in the oil phase solution containing acid chloride monomer for 20s Interface reaction, take out and drain the excess oil phase solution on the surface of the membrane, continue to heat treatment at a temperature of 90 °C for 4 minutes, and spray a v...

Embodiment 2

[0065] A novel high-flux positively charged nanofiltration membrane preparation method:

[0066] The mass concentration of sodium lauryl sulfate in step S1 is 0.1%;

[0067] All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com