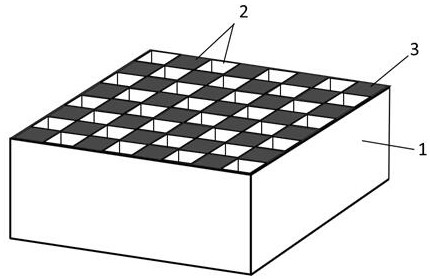

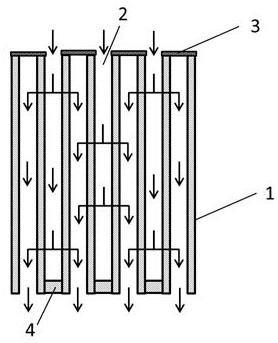

Wall flow type honeycomb formaldehyde-removing air conditioner filter element

A honeycomb and wall-flow technology, which is applied in the direction of dispersed particle filtration, gas treatment, membrane technology, etc., can solve the problems that the coating adsorption and durability are difficult to guarantee, so as to improve the utilization rate of materials, increase the adsorption rate, reduce the The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) 200 g of ceramic fibers with a diameter of about 3 μm and a length of 200 μm have a specific surface area of 510 m 2 ZSM-5 molecular sieve / g, content is 280 g of alkaline silica sol of 30%, polystyrene emulsion 30 g, scallop powder 20 g, 90 ml of water are mixed, then adopt stirrer to stir for 30 minutes, practice in the vacuum mud mixer Mud for 10 minutes to obtain a uniform air-free mud.

[0033] (2) Use a hydraulic press and a honeycomb mold to extrude the mud into a crude honeycomb wet billet with a cross-section of 100mm×100mm square, and cut it into a 100mm×100mm×100mm square honeycomb wet billet by a wet billet cutting machine. The honeycomb hole is 2.5 mm × 2.5 mm square, and the hole wall thickness is 1.5 mm.

[0034] (3) The honeycomb wet billet was air-dried indoors for 36 h, then dried in an oven at 120 °C for 12 h, and then calcined at 550 °C for 6 h in a roaster to form an activated honeycomb filter material (honeycomb body).

[0035] (4) Adhere th...

Embodiment 2

[0037] (1) 220 g of ceramic fibers with a diameter of about 2 μm and a length of 500 μm have a specific surface area of 1240 m 2 The gac powder of / g, content is 260 g of neutral silica sol of 30%, polystyrene emulsion 40g, scallop powder 20 g, add to 110ml water and mix, then adopt stirrer to stir 20 minutes, practice mud in the vacuum mud mixer After 20 minutes, a uniform air-free mud was obtained.

[0038] (2) Use a hydraulic press and a honeycomb mold to extrude the mud into a crude honeycomb wet billet with a cross-section of 100mm×100mm square, and cut it into a rectangular honeycomb wet billet of 100mm×100mm×80mm by a wet billet cutting machine. The honeycomb hole is 1.5 mm × 1.5 mm square, and the hole wall thickness is 1 mm.

[0039] (3) Then put the honeycomb wet billet in the room to dry naturally for 26 hours, then bake it in a muffle furnace at 120°C for 6 hours, and seal and bake it at 550°C for 6 hours to form an activated honeycomb filter material (honeycomb...

Embodiment 3

[0042] (1) 200g of ceramic fibers with a diameter of about 5μm and a length of 400mm, 580g of ceramic fibers with a specific surface area of 60m 2 Manganese oxide per gram, 88g of aluminum sol, 20g of acrylic acid emulsion, and 20g of scallop powder were added to 190ml of water and mixed, then stirred for 20 minutes with a mixer, and 20 minutes of mud was practiced in a vacuum mud mixer to obtain a uniform air-free mud. .

[0043](2) Use a hydraulic press and a honeycomb mold to extrude the mud into a honeycomb wet billet with a cross-section of 150mm×150mm square, and cut it into a 150mm×150mm×100mm rectangular honeycomb wet billet by a wet billet cutting machine. The honeycomb hole is 2.5 mm × 2.5 mm square, and the hole wall thickness is 1.5 mm.

[0044] (3) Then put the honeycomb wet billet in the room to dry naturally for 12 hours, then bake it in a muffle furnace at 120°C for 6 hours, and seal and bake it at 550°C for 6 hours to form an activated honeycomb filter mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole wall thickness | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com