High-power heat dissipation circuit structure

A circuit structure, high-power technology, used in power amplifiers, amplifiers, electrical components, etc., can solve the problems of high-power chip heat dissipation that cannot be effectively solved, reduce reliability, and increase system volume, optimize heat dissipation characteristics, reduce System cost, the effect of improving integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

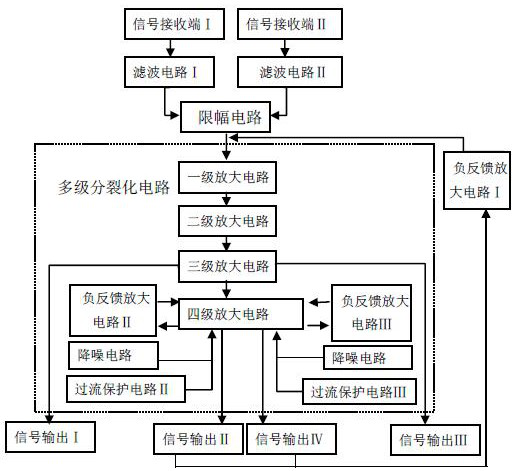

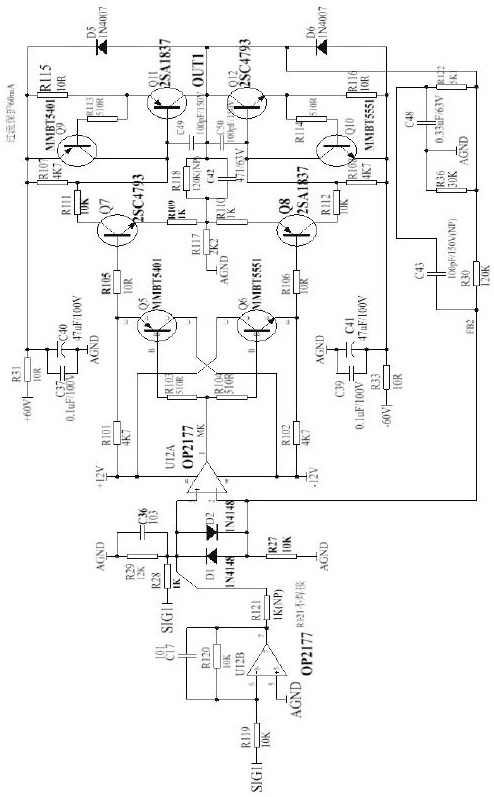

[0039] A high-power heat dissipation circuit structure of the present invention, its circuit structure comprises from front to back: a preprocessing part of an input signal, a power amplification part of a signal and a signal output part, and the preprocessing part of an input signal includes a signal receiving end, a filter circuit , a limiter circuit, the limiter circuit is composed of two reverse diodes D1 and diode D2 connected in parallel, such as figure 1 shown.

[0040] There are two signal receiving ends, and the two signals respectively pass through their own filter circuits and enter the power amplification part of the signal through the limiting circuit;

[0041] The power amplifying part of the signal includes a high-power operational amplifier circuit, negative feedback circuits I, II, and III.

[0042] The high-power operational amplifier circuit is realized by a multi-stage serialization circuit:

[0043] After the input signal passes through the preprocessing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com