Device for reducing background leakage rate of large vacuum chamber at high temperature

A vacuum chamber and high-vacuum technology, applied to measuring devices, using liquid/vacuum degree for liquid tightness measurement, and detecting the appearance of fluid at the leakage point, etc., can solve the problem of difficulty in reducing the leakage rate, high maintenance and repair costs, and low maintenance costs. Problems such as bottom leakage rate and system sensitivity are poor, so as to achieve the effect of increasing gas compression ratio, improving detection sensitivity, and improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

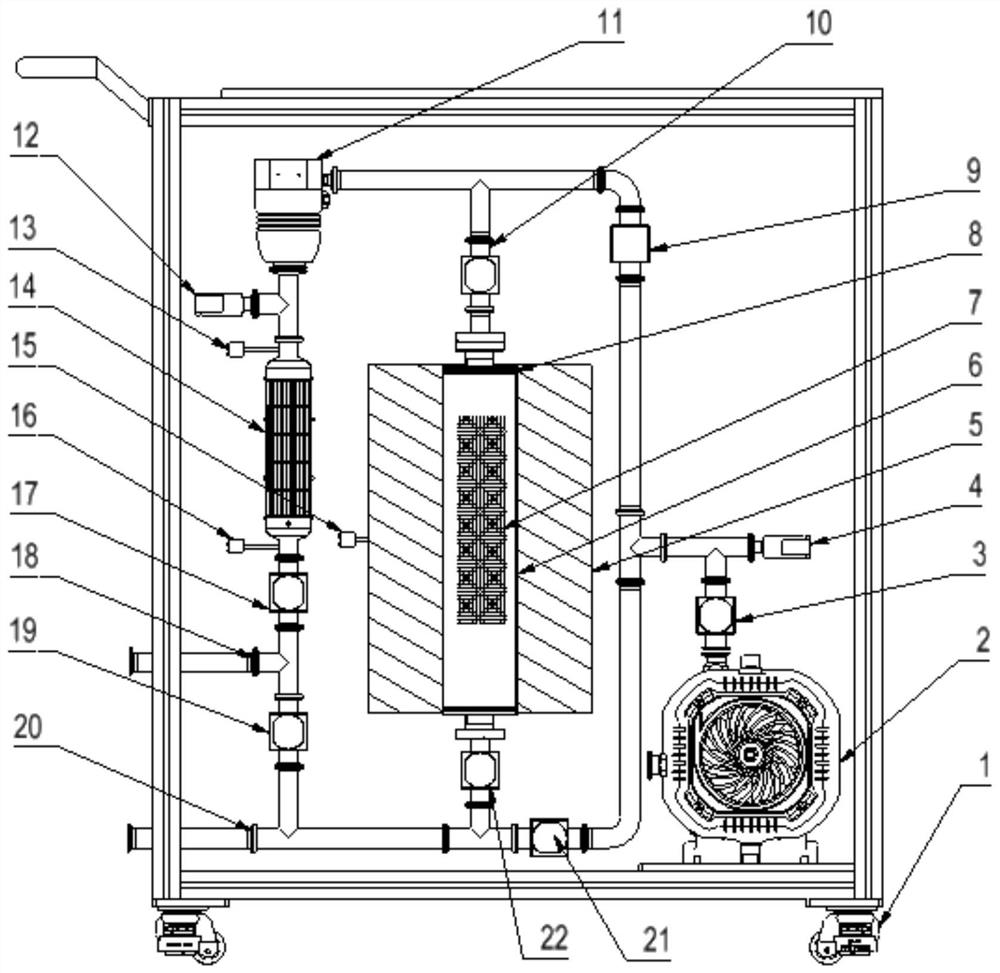

[0025] A device for reducing the background leak rate of a large vacuum chamber at high temperature provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as figure 1 As shown, the present invention provides a device for reducing the background leakage rate of a large vacuum chamber at high temperature, including a dry pump 2, a reaction furnace 5, a heating wire 6, a getter material 7, a molecular pump 11, and a liquid nitrogen heat exchanger 14 ,

[0027] The dry pump 2, the reaction furnace 5, the heating wire 6, the getter material 7, the molecular pump 11, and the liquid nitrogen heat exchanger 14 are installed inside the box body, and the dry pump 2 is fixedly installed at the bottom of the box body, and is connected with High vacuum flapper valve A3, high vacuum flapper valve A3 is connected with the three-way pipeline, one end of the three-way pipeline is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com