High-bearing composite material parting tooth connecting device based on soft substance

A technology of composite material and composite material plate, which is applied in the direction of rod connection, shrinkage connection, thin plate connection, etc., can solve the problems of uneven force transmission, large bolt force, joint damage and other problems of composite material connection technology, and achieve light weight, Effect of reducing weight and improving fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

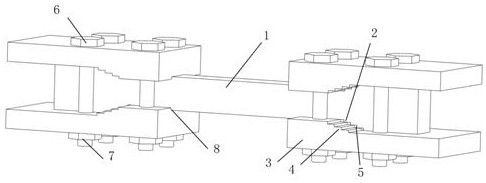

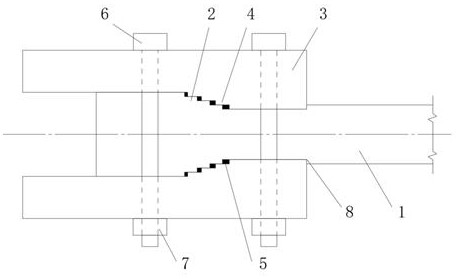

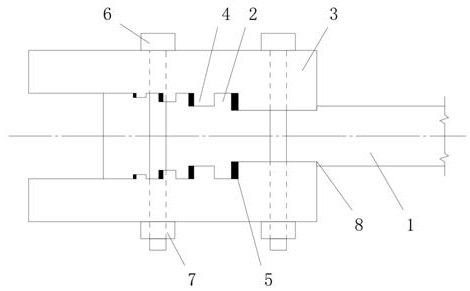

[0033] Such as figure 1 , 2, 3, 4, the present invention is based on the structure of the first embodiment of the high-load-bearing composite material parting tooth connection device based on soft matter, including a composite material plate 1, and the composite material plate 1 is preferably a carbon fiber composite material, which has a higher The strength and hardness meet the requirements of use; the composite material plate 1 is plate-shaped, and the upper side, or lower side, or upper and lower sides of both ends of the composite material are processed into multi-level composite material fractal teeth 2 along the thickness direction, fractal The teeth are stepped or nested with large and small teeth, etc. The upper and lower sides of the two ends of the composite material plate 1 are respectively connected with the metal plate 3, and the connecting surface of the metal plate 3 is processed into a corresponding form of metal teeth 4, that is, metal Teeth 4 and composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com