ATO-coated cesium-tungsten bronze composite nano-powder and preparation method thereof

A technology for coating cesium tungsten bronze and cesium tungsten bronze, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as insufficient stability of cesium tungsten bronze, achieve excellent chemical stability, excellent dispersion, control easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

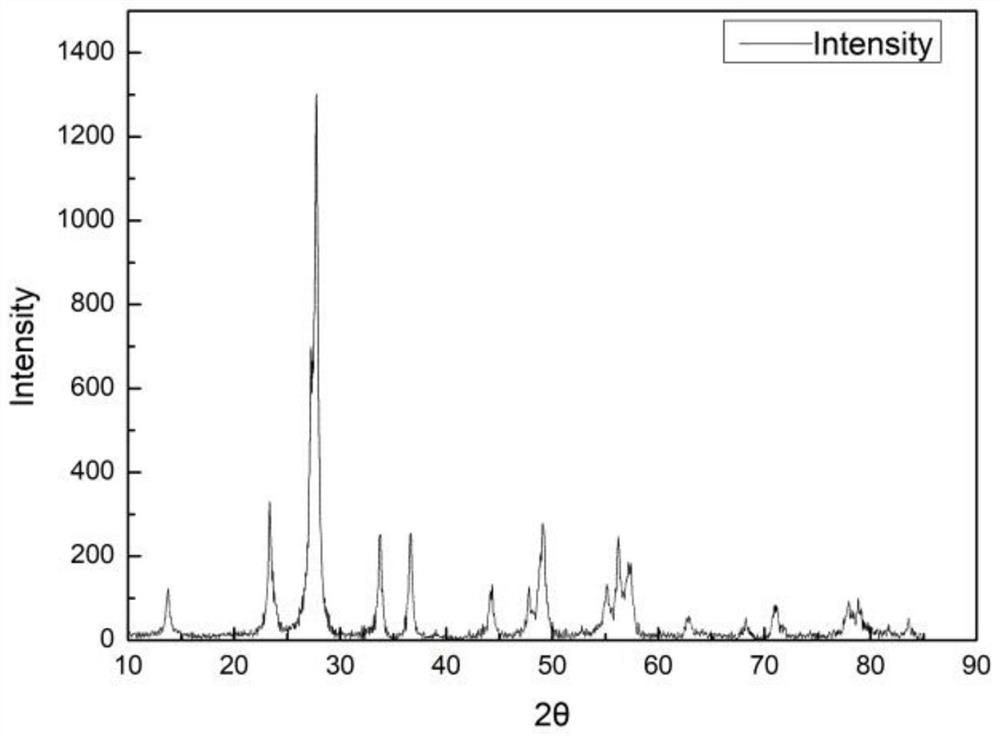

[0078] 1.5mmol WCl 6 Dissolve in 40ml of absolute ethanol, and stir magnetically at room temperature for 10min to obtain a yellow solution. In a separate beaker, mix 0.5 mmol CsOH·H 2O was dispersed in 20ml absolute ethanol. Add the obtained cesium hydroxide alcoholic solution and 12ml of glacial acetic acid into the tungsten hexachloride alcoholic solution to obtain a yellow solution. The solution was poured into a hydrothermal reaction kettle, and after the temperature was raised to 220° C., the reaction was carried out for 12 hours. After the reaction is finished, the precursor solution is taken out after the reactor is cooled to room temperature. The resulting precursor solution was washed three times with deionized water and absolute ethanol, and centrifuged several times; dried in an oven at 60°C for 12 hours to obtain dark blue nano-Cs 0.33 WO 3 Powder sample, the particle size is 110-130nm.

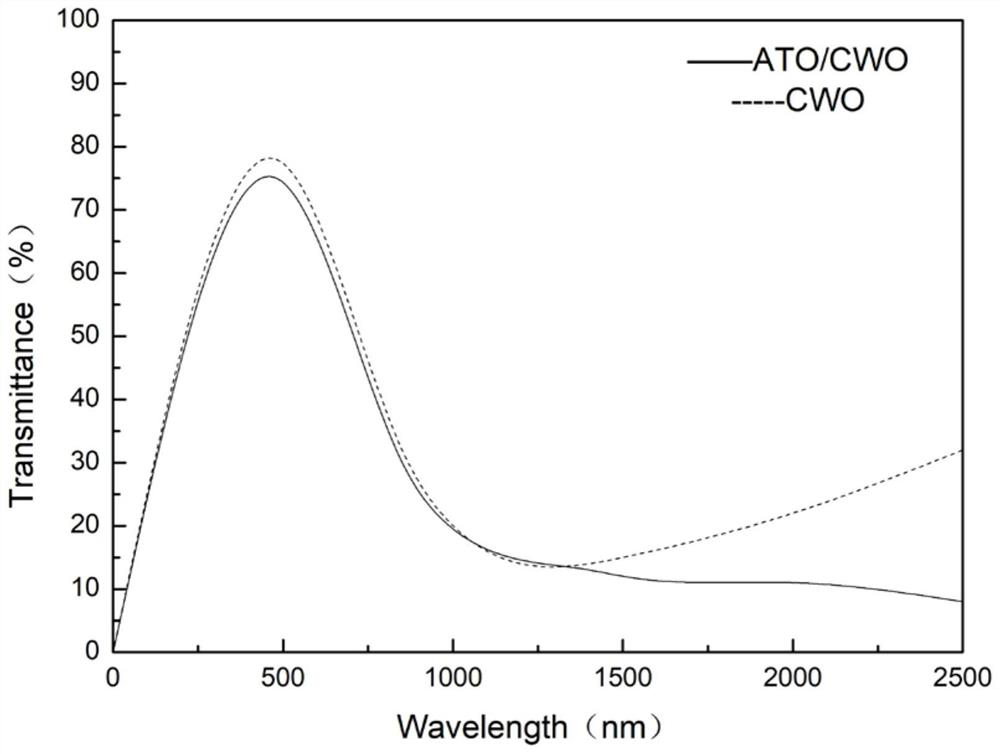

[0079] Disperse 2 g of the cesium tungsten bronze powder in absolute et...

Embodiment 2

[0084] 1.5mmolWCl 6 Dissolve in 40ml of absolute ethanol, and stir magnetically at room temperature for 10min to obtain a yellow solution. In a separate beaker, mix 0.25mmoCsOH·H 2 O was dispersed in 20ml absolute ethanol. Add the obtained cesium hydroxide alcoholic solution and 12ml of glacial acetic acid into the tungsten hexachloride alcoholic solution to obtain a yellow solution. The solution was poured into a hydrothermal reaction kettle, and the temperature was raised to 240° C., and reacted for 10 h. After the reaction is finished, the precursor solution is taken out after the reactor is cooled to room temperature. The resulting precursor solution was washed three times with deionized water and absolute ethanol, and centrifuged several times; dried in an oven at 60°C for 12 hours to obtain dark blue nano-Cs 0.17 WO 3 Powder sample, the particle size is 110-130nm.

[0085] Disperse 2 g of the cesium tungsten bronze powder in absolute ethanol, add polyethylene glyco...

Embodiment 3

[0089] 1.5mmol WCl 6 Dissolve in 40ml of absolute ethanol, and stir magnetically at room temperature for 10min to obtain a yellow solution. In a separate beaker, mix 0.375 mmol CsOH·H 2 O was dispersed in 20ml absolute ethanol. Add the obtained cesium hydroxide alcoholic solution and 12ml of glacial acetic acid into the tungsten hexachloride alcoholic solution to obtain a yellow solution. The solution was poured into a hydrothermal reaction kettle, and the temperature was raised to 240° C., and reacted for 10 h. After the reaction is finished, the precursor solution is taken out after the reactor is cooled to room temperature. The resulting precursor solution was washed three times with deionized water and absolute ethanol, and centrifuged several times; dried in an oven at 60°C for 12 hours to obtain dark blue nano-Cs 0.25 WO 3 Powder sample, the particle size is 110-130nm.

[0090] Disperse 2 g of the cesium tungsten bronze powder in absolute ethanol, add a dispersant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com