Light super-strong aerogel heat insulation coating and preparation method thereof

A technology of thermal insulation coating and aerogel, which is applied in fire-resistant coatings, alkali metal silicate coatings, coatings, etc., to achieve the effect of improving thermal insulation performance, good mechanical performance and excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

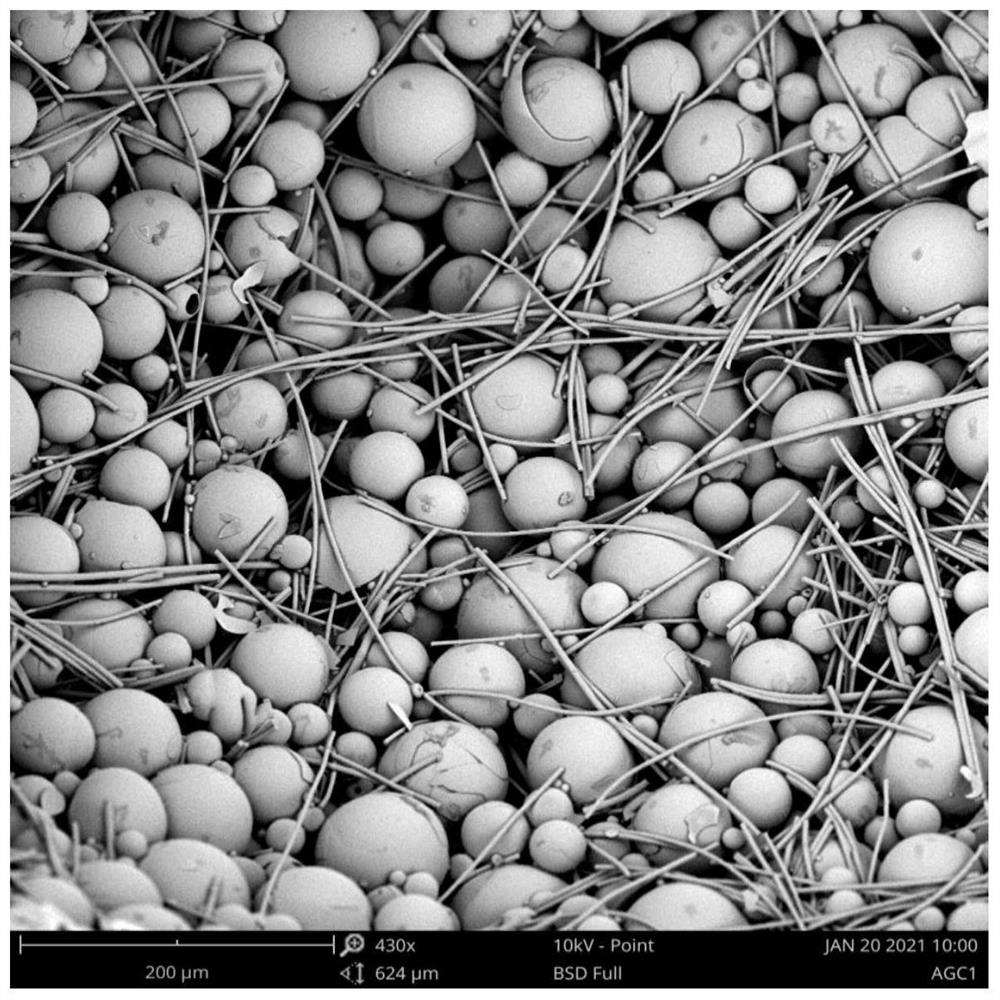

[0041] (1) Take 50 parts of potassium sodium silicate, 100 parts of deionized water and 4 parts of sodium carboxymethylcellulose, place them in a stirring container, stir at a speed of 300rpm for 30min, and after the sodium carboxymethylcellulose is fully dissolved, Add 30 parts of mullite fiber loose cotton (diameter 3-5 μm), and stir at a speed of 500 rpm for 30 minutes to obtain a uniformly dispersed fiber slurry;

[0042] (2) Take 50 parts of deionized water, 3 parts of sodium lauryl sulfate and 0.5 part of dimethylmaleate ammonium salt dispersant, put them in a stirring container, stir at a speed of 100rpm for 10min, and wait until the solvents are fully mixed , adding 5 parts of silica airgel powder (particle size 2-40 μm), stirring at a speed of 300 rpm for 120 min to obtain an aqueous dispersion of silica airgel;

[0043] (3) Add the fiber slurry in step (1) and the water dispersion of silica airgel in step (2) to the stirring vessel, stir at a speed of 500rpm for 30mi...

Embodiment 2

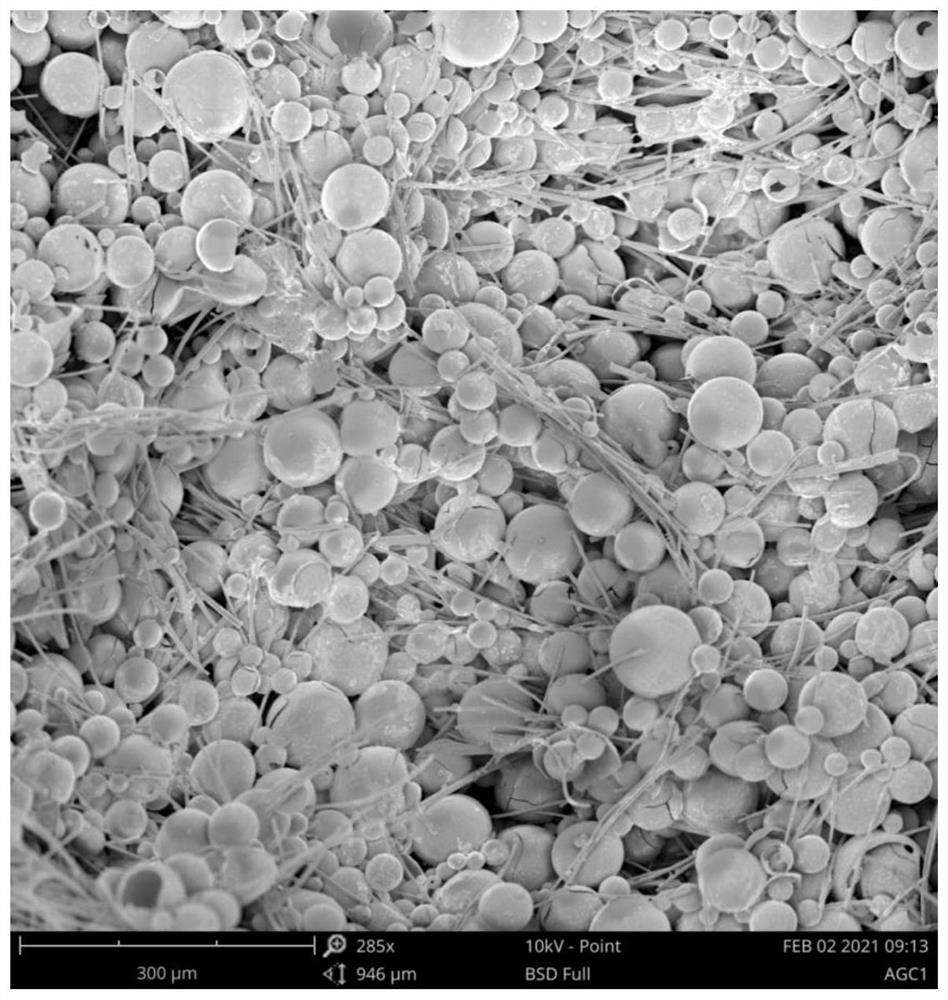

[0047] (1) Take 60 parts of potassium sodium silicate, 50 parts of deionized water and 3 parts of sodium alginate, put them in a stirring container, and stir at a speed of 300 rpm for 30 minutes. After the sodium alginate is fully dissolved, add 50 parts of zirconia fiber Loose cotton (3-8 μm in diameter), stirring at a speed of 500 rpm for 30 minutes to obtain a uniformly dispersed fiber slurry;

[0048] (2) Take 80 parts of deionized water, 4 parts of sodium dodecylbenzenesulfonate and 1 part of dimethylmaleate ammonium salt dispersant, put them in a stirring container, stir at a speed of 300rpm for 10min, and wait until the solvent is fully After mixing, add 8 parts of alumina airgel powder (particle size 2-40 μm), and stir at a speed of 500 rpm for 120 minutes to obtain an aqueous dispersion of alumina airgel;

[0049] (3) Add the fiber slurry in step (1) and the aqueous dispersion of silica airgel in step (2) to the stirring vessel, stir at a speed of 500rpm for 20min, an...

Embodiment 3

[0053] (1) Take 100 parts of potassium sodium silicate, 150 parts of deionized water and 6 parts of attapulgite, put them in a stirring container, and stir at a speed of 300 rpm for 5 minutes. After the attapulgite is fully dispersed, add 10 parts of alumina fiber Loose cotton (diameter 3-4μm), stirring at 800rpm for 30min to obtain evenly dispersed fiber slurry;

[0054] (2) Take 120 parts of deionized water, 10 parts of fatty alcohol sodium sulfate and 2 parts of dimethyl succinate ammonium salt dispersant, put them in a stirring container, and stir at a speed of 100 rpm for 20 minutes. After the solvent is fully mixed, add 15 One part of titanium dioxide airgel powder (2~40 μm in particle size), stirred at a speed of 300 rpm for 120 min to obtain an aqueous dispersion of titanium dioxide airgel;

[0055] (3) Add the fiber slurry in step (1) and the water dispersion of silica airgel in step (2) to the stirring vessel, stir at a speed of 400rpm for 30min, and then , add 50 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com