Method for adjusting formula of circulating water scale and corrosion inhibitor on basis of calcium-alkali ratio of make-up water

A technology of scale and corrosion inhibitor, scale inhibitor, applied in chemical instruments and methods, water/sludge/sewage treatment, natural water treatment, etc. , to achieve the effect of enhancing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

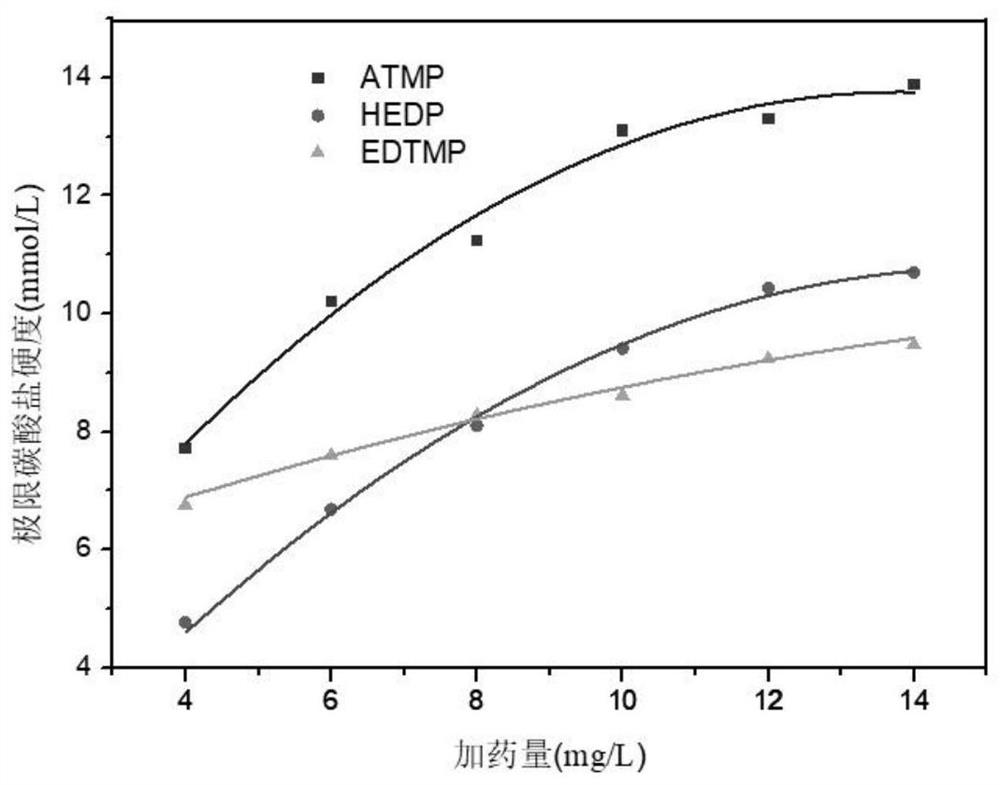

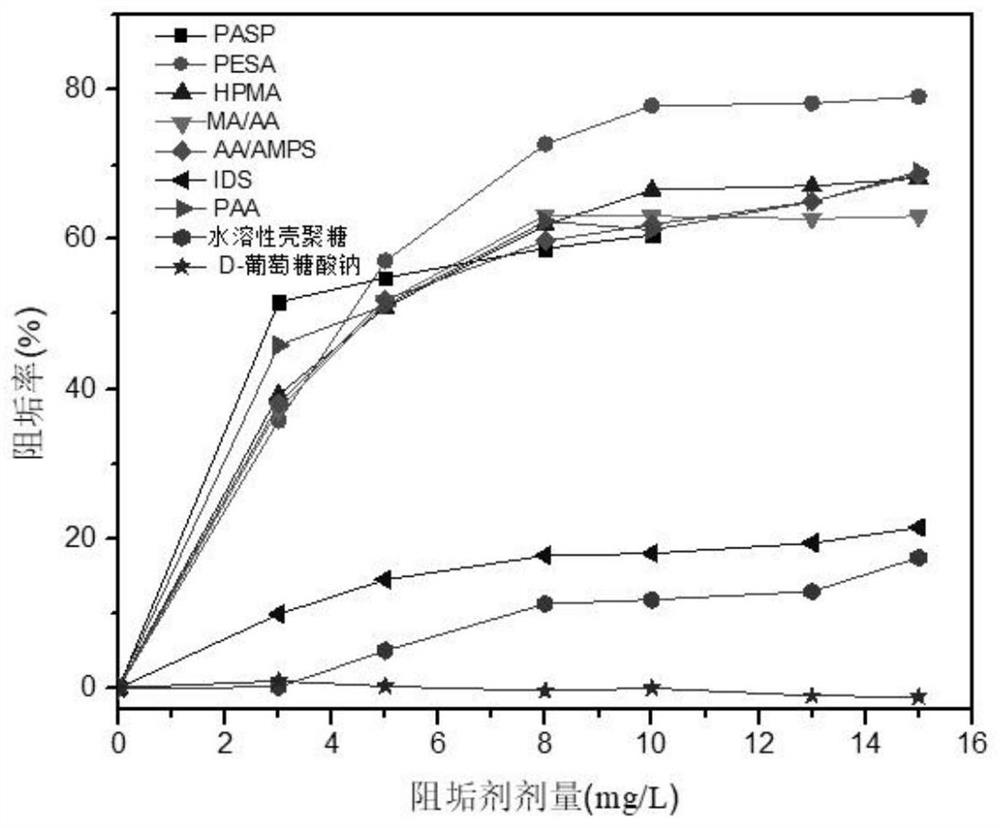

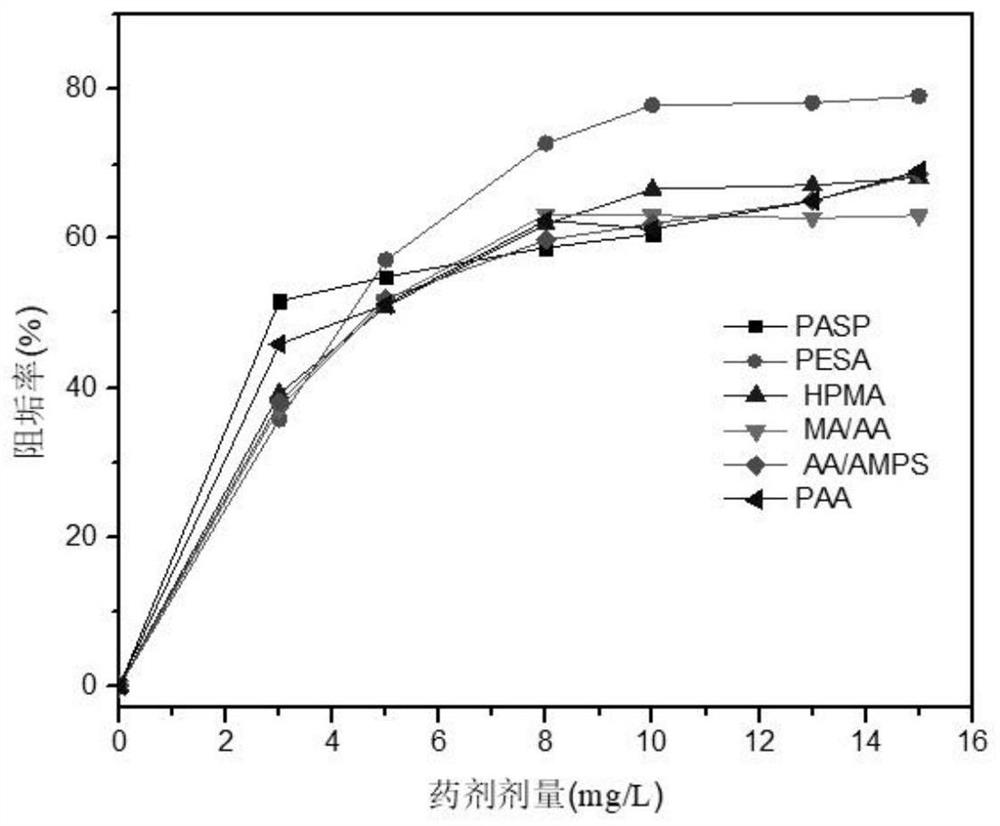

[0029] The screening of embodiment 1 antiscalant monomer

[0030] The scale inhibitor information used in the present invention is shown in Table 1.

[0031] Table 1 Antiscalant information

[0032] serial number name abbreviation form Solid content 1 Amino trimethylene phosphonic acid ATMP liquid 50% 2 Hydroxyethylene diphosphate HEDP liquid 50% 3 Ethylenediaminetetramethylenephosphonic acid EDTMP liquid 18-20% 4 sodium polyaspartate PASP liquid 40% 5 polyepoxysuccinic acid PESA liquid 40% 6 Hydrolyzed Polymaleic Anhydride HPMA liquid 48% 7 Maleic acid-acrylic acid copolymer MA / AA liquid 48% 8 Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer AA / AMPS liquid 30% 9 Tetrasodium iminodisuccinate IDS liquid 33-35% 10 Polyacrylic acid PAAA liquid 30% 11 Water Soluble Chitosan / solid 100% 12 Sodium D-gluconate / solid 99% ...

Embodiment 2

[0038] The screening of embodiment 2 antiscalant formula

[0039] A, B, C, and D represent organic phosphine antiscalant monomer ATMP, dispersed antiscalant monomer MA / AA, dispersed antiscalant monomer AA / AMPS, and dispersed antiscalant monomer PASP , the scheme is as follows:

[0040] (1) Determine the boundary of each antiscalant ratio (mixture component, that is, the ratio of a single antiscalant to the total amount of antiscalant), as shown in Table 2.

[0041] Table 2 The ratio range of each antiscalant

[0042]

[0043] (2) Mixing homogeneity test using simplex center of gravity design, as shown in Table 3.

[0044] Table 3 Experimental design table

[0045] Numbering A B C D 1 1 0 0 0 2 0 1 0 0 3 0 0 1 0 4 0 0 0 1 5 0.5 0.5 0 0 6 0.5 0 0.5 0 7 0.5 0 0 0.5 8 0 0.5 0.5 0 9 0 0.5 0 0.5 10 0 0 0.5 0.5 11 0.33 0.33 0.33 0 12 0.33 0.33 0 0.33 13 0.33 0 0.33...

Embodiment 3

[0121] The adjustment method of embodiment 3 antiscalant formula

[0122] Adjust the formula of scale and corrosion inhibitors for circulating water based on the calcium-alkaline ratio of supplemented water. The supplementary water of a certain power plant has two water sources: surface water and urban reclaimed water. Since the amount of urban reclaimed water is not fixed, the proportion of surface water and urban reclaimed water in the replenishment water varies greatly from day to day. The analysis of supplementary water quality is shown in Table 17.

[0123] Table 17 Water quality analysis of a power plant make-up water

[0124] Test items surface water Reclaimed water treatment system effluent Turbidity (NTU) 0.97 1.42 Conductivity (μS / cm) 698 1121 pH 8.0 8.1 Alkalinity of phenolphthalein (mmol / L) 0 0 Total Alkalinity (mmol / L) 2.76 2.15 Ca 2+ (as CaCO 3 Count) (mg / L)

98 350 Total hardness (as CaCO 3 Count...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com