Layer drawer type echelon cooling in-situ marinating device and method

An equipment and cascade technology, which is applied in the field of drawer type cascade cooling in-situ halogenation equipment, can solve the problems of unstable quality, large differences in product quality between batches, serious material and energy consumption, etc., to facilitate the extraction and improve the halogenation effect. , enhance the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

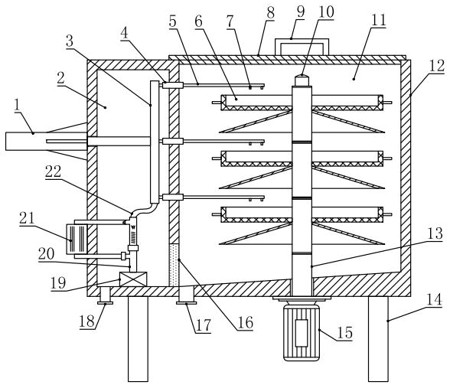

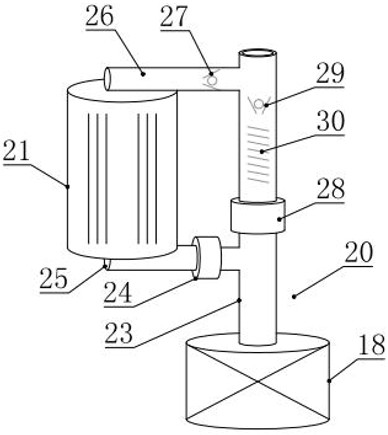

[0025] see Figure 1-4 , in an embodiment of the present invention, a drawer-type cascade cooling in-situ stewing equipment includes a main body 12, the left and right sides of the main body 12 are respectively provided with a first chamber 2 and a second chamber 11, the second The bottom of the chamber 11 is also provided with a heating device, and the top of the equipment main body 12 is also equipped with a case cover 8 for covering the second chamber 11. A handle 9 is installed on the case cover 8, and the bottom of the equipment main body 12 A plurality of supporting legs 14 are also installed, through which the device can be stably supported.

[0026] The middle of the bottom of the second chamber 11 is rotatably installed with a rotating column 13, and the upper end of the rotating column 13 is installed and fixed with a mounting column 10. There are multiple groups of halogen drawer assemblies 6 detachably mounted on the mounting column 10. The main body of the device ...

Embodiment 2

[0038] see Figure 1-4 , in an embodiment of the present invention, a method for stewing in-situ stewing equipment with drawer-type cascade cooling, comprising the following steps:

[0039] Step 1. By controlling the contraction of the telescopic cylinder 1, the whole body composed of the infusion main pipe 3 and the infusion branch pipe 5 is driven to move to the left; then the products that need to be stewed are placed in the stewed drawer assembly 6, and the stewed drawer assemblies 6 are inserted in sequence onto the mounting post 10;

[0040] Step 2: Inject stewed soup into the second chamber 11 to submerge the uppermost stewed drawer assembly 6; then control the heating device at the bottom of the second chamber 11 to heat the stewed soup to 90-95°C for 60-60°C 80 minutes; during the stewing process, the rotating motor 15 is controlled to work at the same time, and the stewed drawer assembly 6 is driven to rotate at a speed of 5-10 r / min, so as to improve the stewed eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com