Composite photothermal conversion material based on shaddock peel as well as preparation and application of composite photothermal conversion material

A technology of grapefruit peel and composite light, applied in the field of solar thermal conversion, can solve the problems of high cost and complicated preparation process, and achieve the effects of ultra-low cost, wide material sources, and improved photothermal conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of grapefruit peel composite photothermal conversion material is prepared by the following steps:

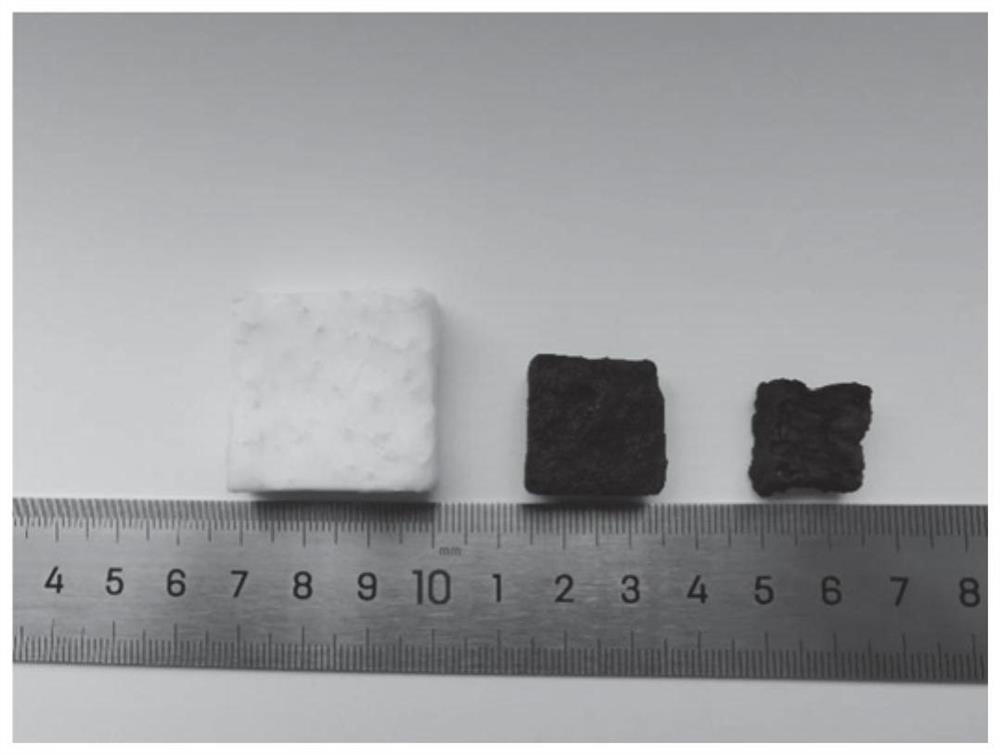

[0038] (1) Take the fresh pomelo peel, cut off the yellow skin and keep the white pomelo sac, the size of the pomelo sac is 3*3*1 (cm);

[0039] (2) Mix pomelo capsules with manganese carbonate and water (concentrations of manganese carbonate aqueous solution are 0, 10, 15, 20mg / ml, use 40ml), and shake for 5h to obtain pomelo capsules adsorbed with manganese carbonate. Manganese pomelo sacs were dried (for example, at 80°C for 10 hours), and the completely dried pomelo sacs adsorbed with manganese carbonate were carbonized. The carbonization treatment conditions were: under nitrogen atmosphere, the heating rate was 5°C / min, After 2 hours of heat preservation, four different grapefruit peel composite photothermal conversion materials were obtained; when the concentration of manganese carbonate aqueous solution was 15 mg / ml, the corresponding grapefruit pee...

Embodiment 2

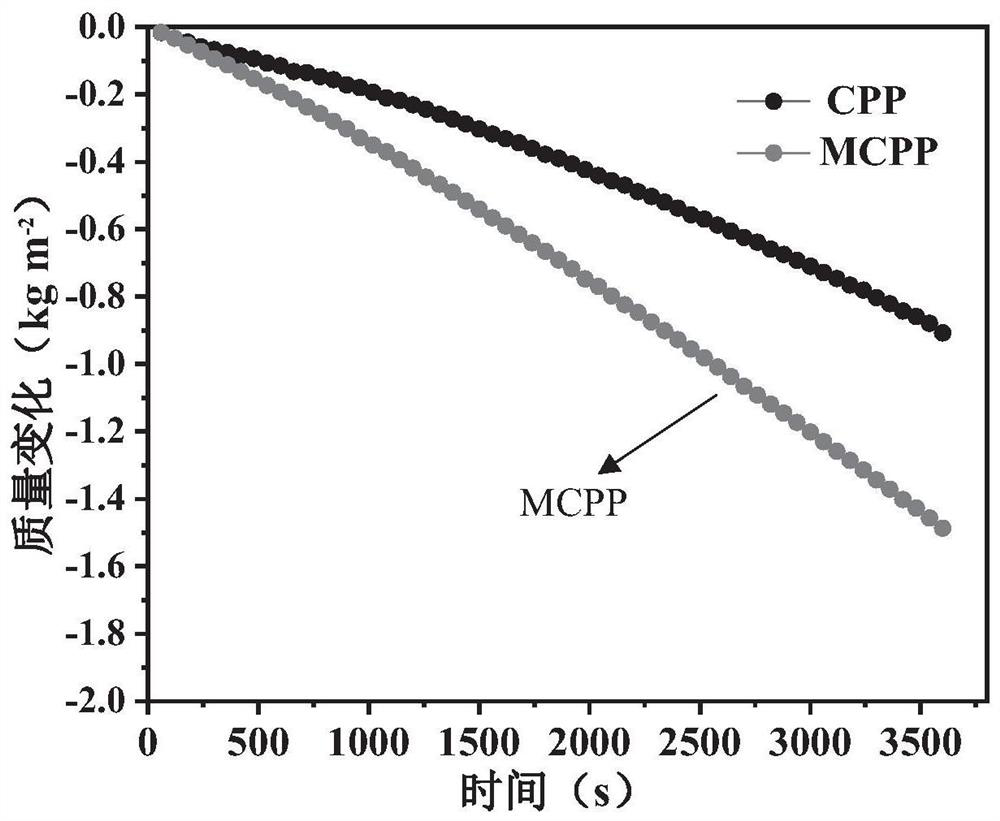

[0041] Example 2, test of distilled water evaporation rate of grapefruit peel composite photothermal conversion material

[0042](1) Place the grapefruit peel composite light-to-heat conversion material (MCPP prepared by 15 mg / ml manganese carbonate) in Example 1 in a foam with a diameter of 2.2 cm that has been cut and a through hole of 2*2 cm in the middle, The light-to-heat conversion material is placed in the through hole of the foam, and it is placed in a container filled with water, and the area of the water surface in the container is greater than or equal to the area of the foam cross section (for example: the foam cross section area is 99% of the water surface area ), and the photothermal conversion material is in direct contact with the water surface. The function of the foam is to avoid the evaporation of water other than the non-grapefruit skin composite light-to-heat conversion material, resulting in a high evaporation rate. Using a solar simulator equipped w...

Embodiment 3

[0046] (1) Fabrication of evaporation device for grapefruit peel composite light-to-heat conversion material

[0047] Schematic diagram of the evaporator Figure 5 As shown, it includes a water storage device 1, a light-to-heat conversion material 5, a water absorbing device and a heat insulating material 3; the water absorbing device includes a water absorbing paper 4 and a water absorbing rod 2, and the heat insulating material 3 is located above the water surface in the water storing device 1, specifically at The open end of the water storage device (seal the open end), the water-absorbing paper 4 is arranged on the upper surface of the heat insulating material 3 (heat-insulating foam, polystyrene foam), the light-to-heat conversion material 5 is placed on the water-absorbing paper 4, and the water-absorbing rod 2 Insert the insulation material 3, one end into the water, and the other end in contact with the absorbent paper 4. The photothermal conversion material is the ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com