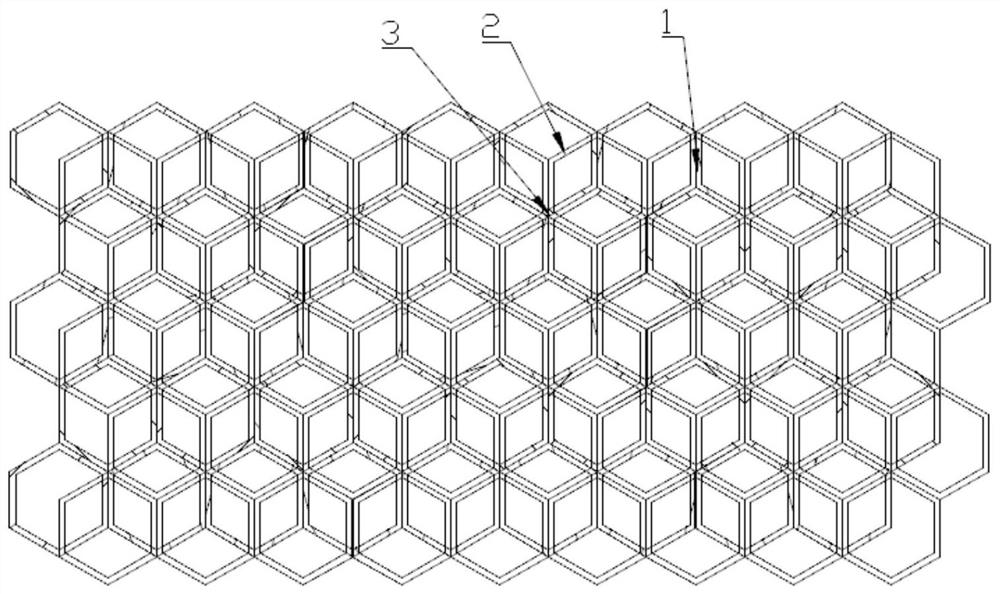

A kind of vacuum insulation material and its preparation method

A vacuum thermal insulation material and thermal insulation technology, applied in heat exchange equipment, chemical instruments and methods, mechanical equipment, etc., can solve problems such as low thermal conductivity, achieve high bonding strength, reduce overall thermal conductivity, and reduce the effect of heat conduction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

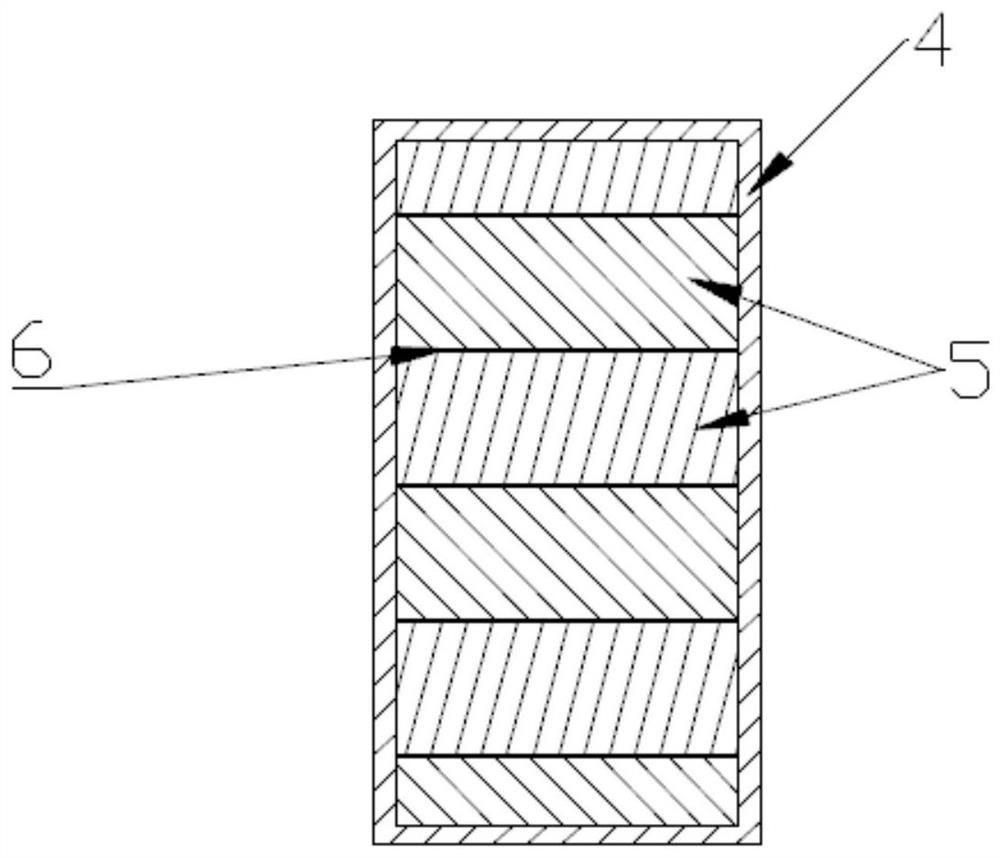

Method used

Image

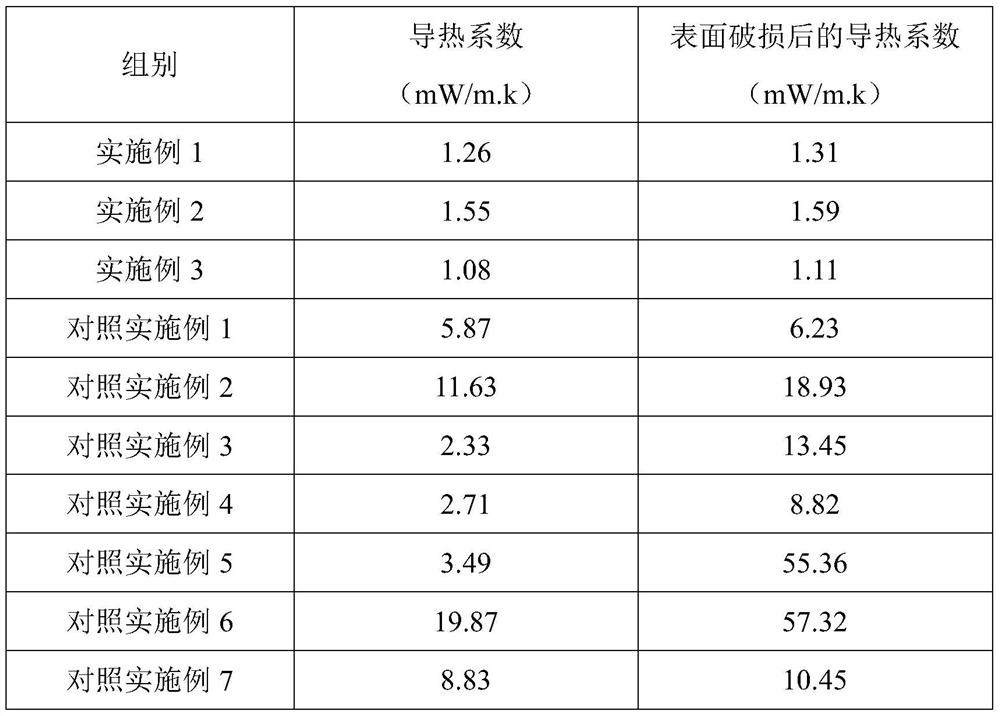

Examples

Embodiment 1

[0035] Example 1: Vacuum insulation panels were prepared as follows:

[0036] (A) Add the silica airgel powder into the epoxy resin according to the mass fraction of silica airgel in the thermal insulation adhesive of 0.1wt%, and stir slowly for later use; the silica airgel The particle size is 0.1-0.3mm, the porosity of the airgel is >90%, the pore size is 30nm, and the bulk density is 0.035g / cm 3 , specific surface area 1100m 2 / g. Due to the low density of silica airgel, too much addition will lead to degumming between the subsequent vacuum column compartments, and the mechanical strength of the airgel is poor, and too much addition will also lead to a decrease in the overall strength of the plate.

[0037] (B) put alkali-free short glass fiber and 4080 fiber into the cotton blender in a weight ratio of 7.5:2.5; the average length of the alkali-free short glass fiber and 4080 fiber is 50mm; enter the carding machine after mixing fiber; then put the mixed fiber into the c...

Embodiment 2

[0042] Example 2: Vacuum insulation panels were prepared as follows:

[0043](A) Add the silica airgel powder into the epoxy resin according to the mass fraction of the silica airgel accounting for the thermal insulation adhesive of 2.5wt%, and stir it slowly for later use; the silica airgel The particle size is 0.1-0.3mm, the porosity of the airgel is >90%, the pore size is 30nm, and the bulk density is 0.035g / cm 3 , specific surface area 1100m 2 / g.

[0044] (B) put alkali-free short glass fiber and 4080 fiber into the cotton blending machine in a weight ratio of 7:2; the average length of the alkali-free short glass fiber and 4080 fiber is 50mm; enter the carding machine after mixing fiber; then put the mixed fiber into the cotton paver according to the thickness of 5mm, 1100g / m 2 Cotton-spread areal density; after drying at 170°C, heat-press molding to obtain the glass fiber core layer.

[0045] (C) Preparation of vacuum column compartment: Lay a layer of copper foil w...

Embodiment 3

[0049] Example 3: Vacuum insulation panels were prepared as follows:

[0050] (A) Add the silica airgel powder into the epoxy resin according to the mass fraction of the silica airgel accounting for the thermal insulation adhesive of 1.3wt%, and stir it slowly for later use; the silica airgel The particle size is 0.1-0.3mm, the porosity of the airgel is >90%, the pore size is 30nm, and the bulk density is 0.035g / cm 3 , specific surface area 1100m 2 / g.

[0051] (B) put alkali-free short glass fiber and 4080 fiber into the cotton blending machine in a weight ratio of 6:4; the average length of the alkali-free short glass fiber and 4080 fiber is 50mm; enter the carding machine after mixing fiber; then put the mixed fiber into the cotton paver according to the thickness of 2mm, 500g / m 2 Cotton-spread areal density; after drying at 170°C, heat-press molding to obtain the glass fiber core layer.

[0052] (C) Preparation of the vacuum column compartment: Lay a layer of copper fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com