Anti-deposition device and method for inlet manifold in slurry high-pressure reciprocating pump

A collection pipe and reciprocating pump technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of large return flow, piston liquid column cut-off, complex components, etc., and achieve easy rotation angle Controlling, reducing the resistance of circulatory motion, reducing the effect of output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

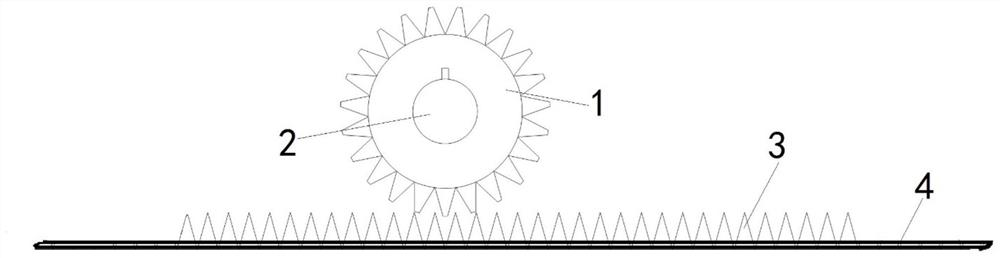

[0045] Such as Figure 6 As shown, the present invention provides an anti-sedimentation device for the inlet manifold of a high-pressure reciprocating pump in a slurry state. In order to avoid the sedimentation and blockage of solid particles in the inlet manifold of a reciprocating pump in a slurry state, the design structure of the slurry state pump is studied in depth, so that in the slurry state A 160° rotating device is provided in the pump inlet manifold to avoid the deposition of solid particles at the lowest end of the pump inlet manifold 14 to reduce the risk of manifold blockage.

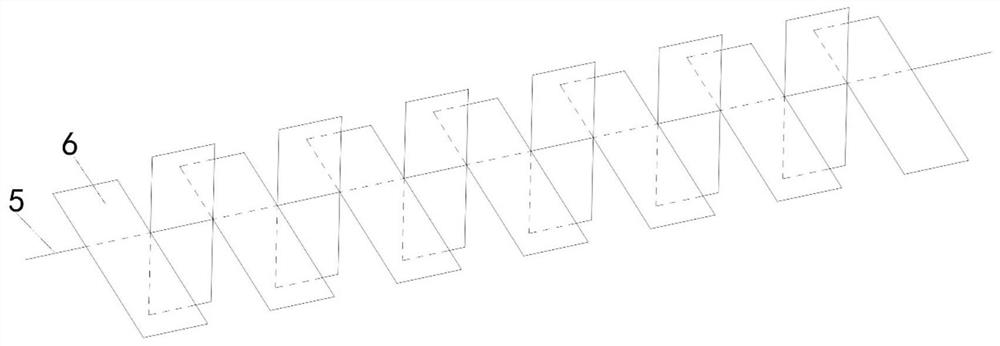

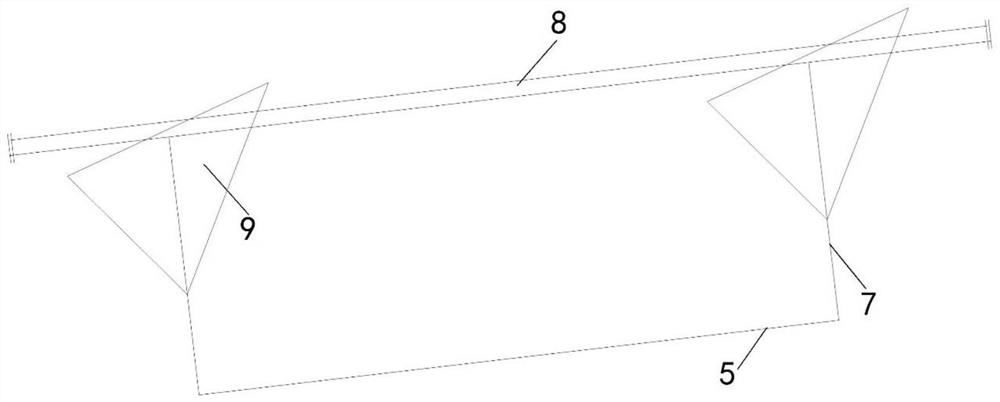

[0046] Such as figure 1 and figure 2 As shown, in this embodiment, the anti-deposition device includes a scraper connecting rod 5, which is arranged in the inner cavity of the inlet manifold 14, and several scraper blades 6 are connected along the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com