Crystallizer

A crystallizer and graphite technology, applied in the field of copper and copper alloy strip billet horizontal continuous casting equipment, can solve the problems of uneven thermal load movement direction, uneven surface and casting lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

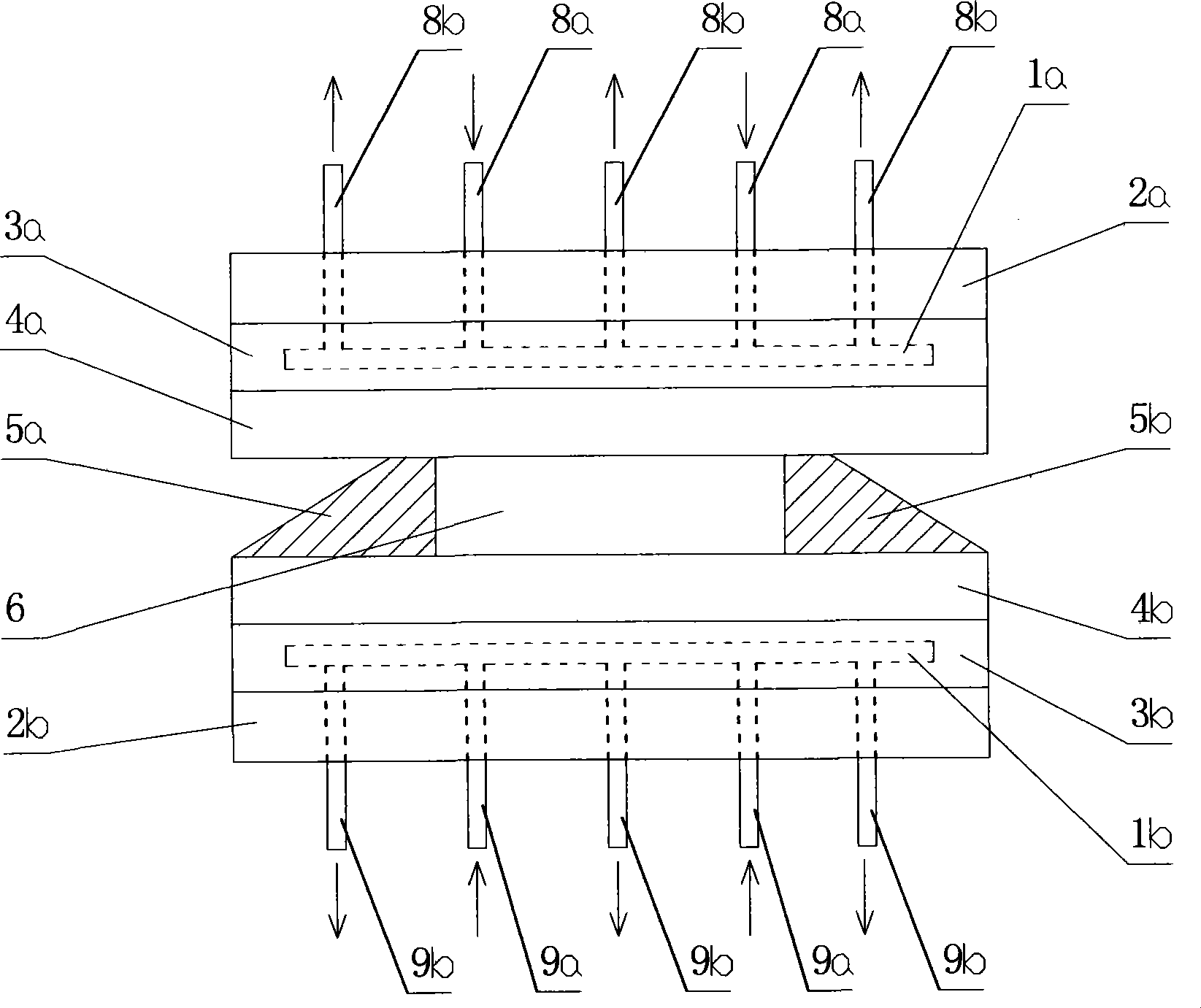

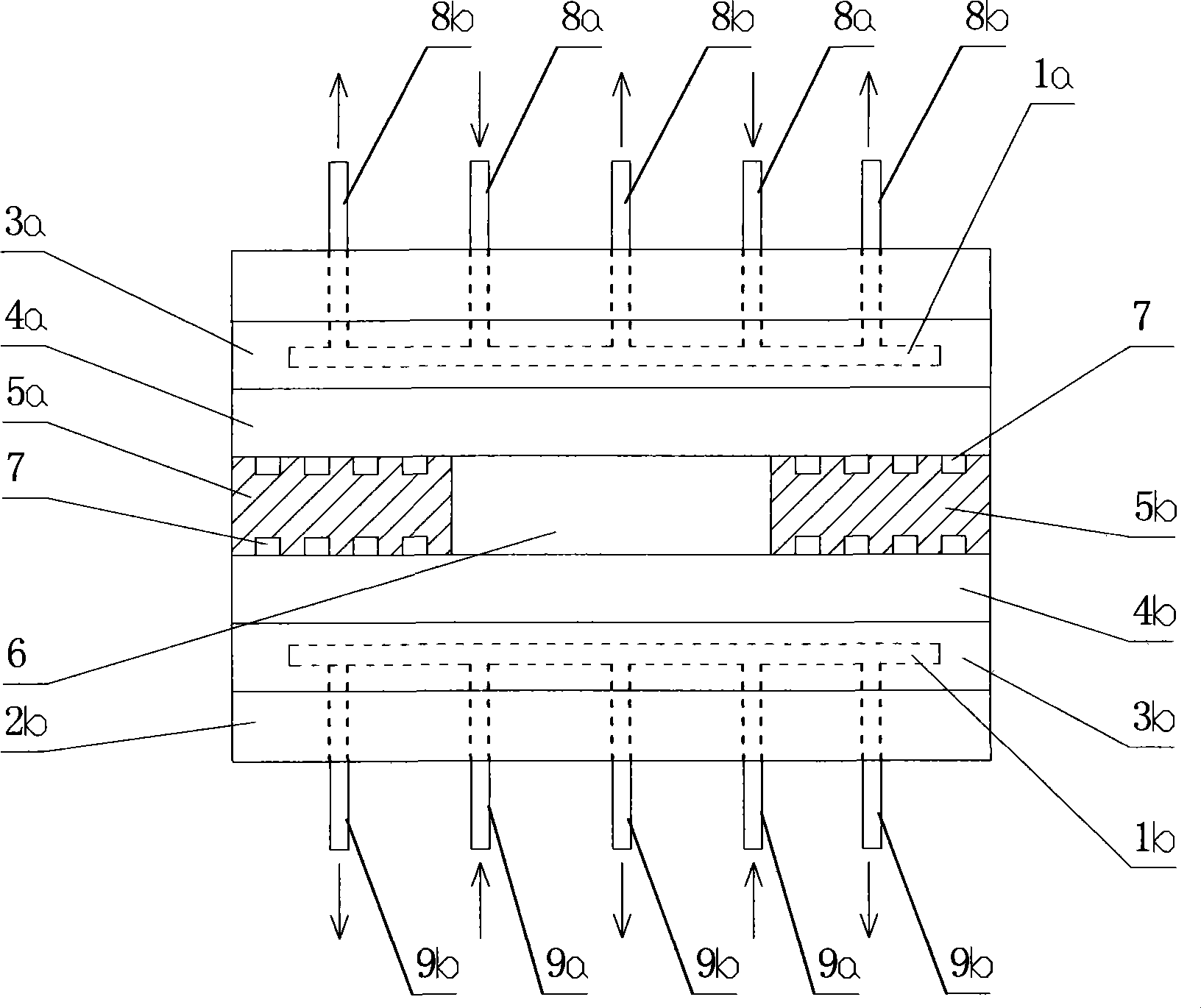

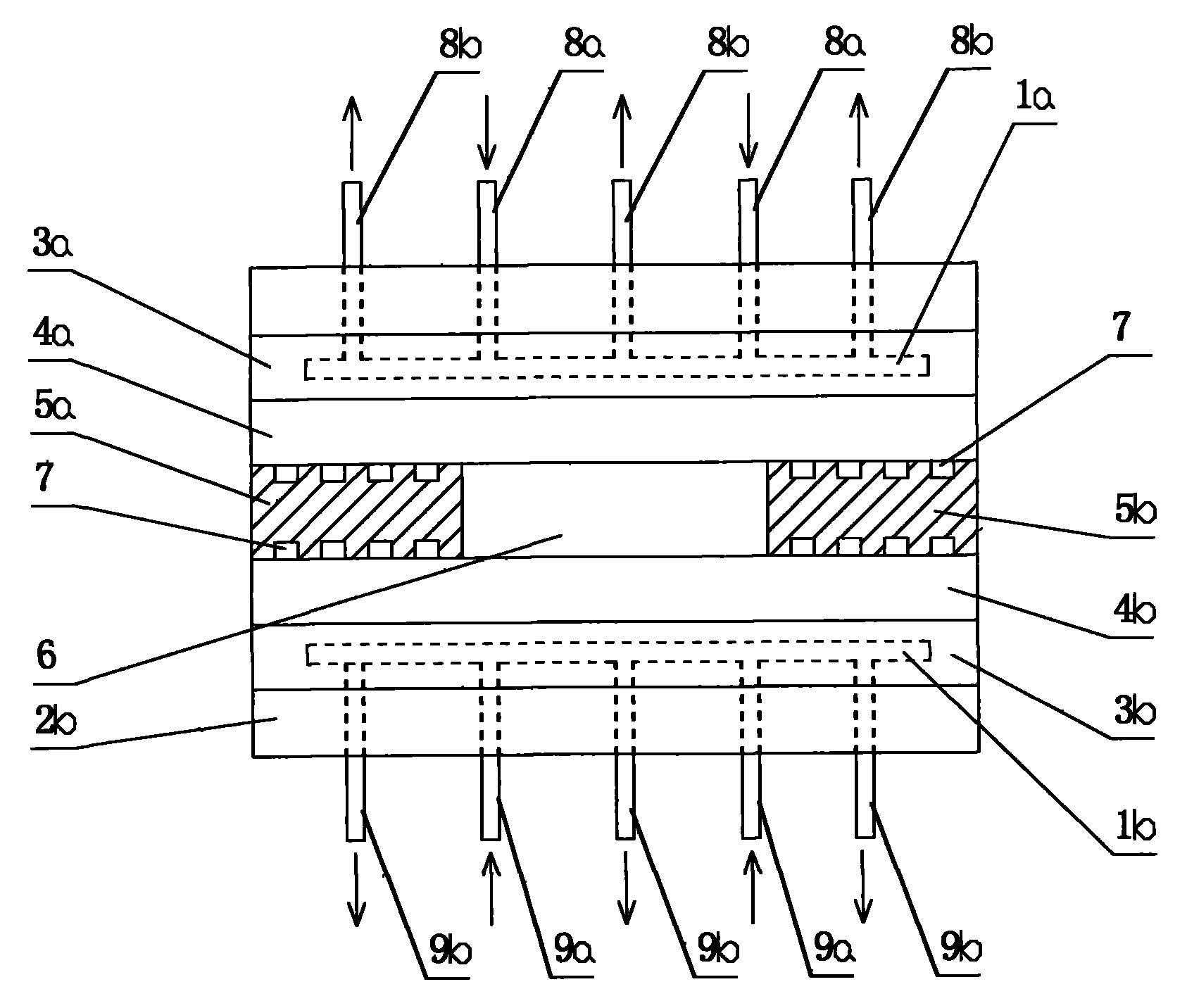

[0014] Such as figure 1 As shown, the crystallizer of the present invention includes an upper graphite plate 4a, a lower graphite plate 4b, a left graphite side strip 5a, a right graphite side strip 5b, an upper copper plate 3a and a lower copper plate with an upper cooling pipeline 1a and a lower cooling pipeline 1b respectively 3b. Wherein the left graphite side bar 5a, the right graphite side bar 5b are installed between the upper graphite plate 4a, the lower graphite plate 4b, and between the upper graphite plate 4a, the lower graphite plate 4b, the left graphite side bar 5a, the right graphite side bar 5b A cavity 6 is formed, and liquid copper water is injected into the cavity 6 for cooling. The upper copper plate 3a is installed above the upper graphite plate 4a, and the lower copper plate 3b is installed under the lower graphite plate 4b, which is the structure of the existing crystallizer.

[0015] The improvement of this case is: the cross-sections of the left grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com