Method for laying concrete cushion and steel pipe in jacking pipe

A technology of concrete cushion and pipe jacking, which is used in pipeline laying and maintenance, pipe/pipe joint/pipe fittings, machinery and equipment, etc., can solve the problems of difficulty in taking out guide rails, low concrete efficiency, and difficulty in guaranteeing, so as to reduce the overall construction time. , to avoid the effect of inability to take out and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] Such as Figure 1 to Figure 8 Shown, a kind of method for laying concrete cushion and steel pipe in pipe jacking, comprises steps:

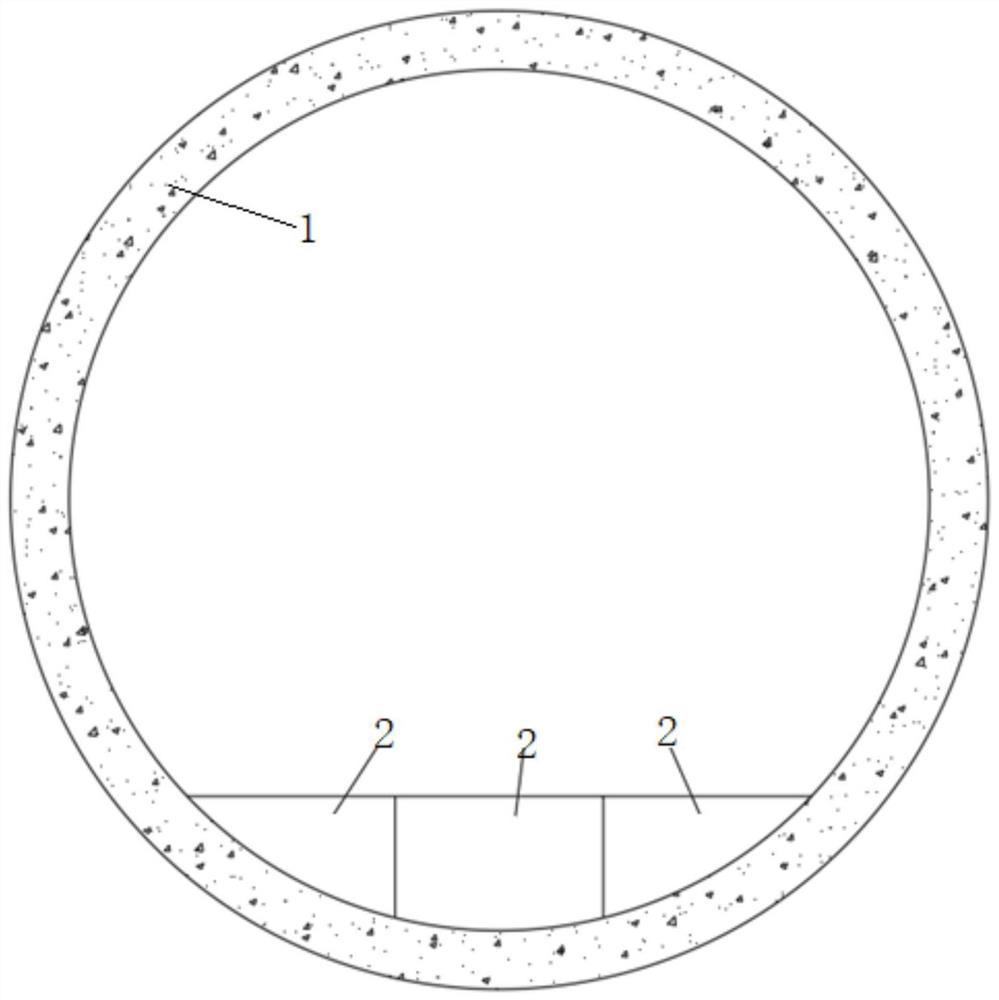

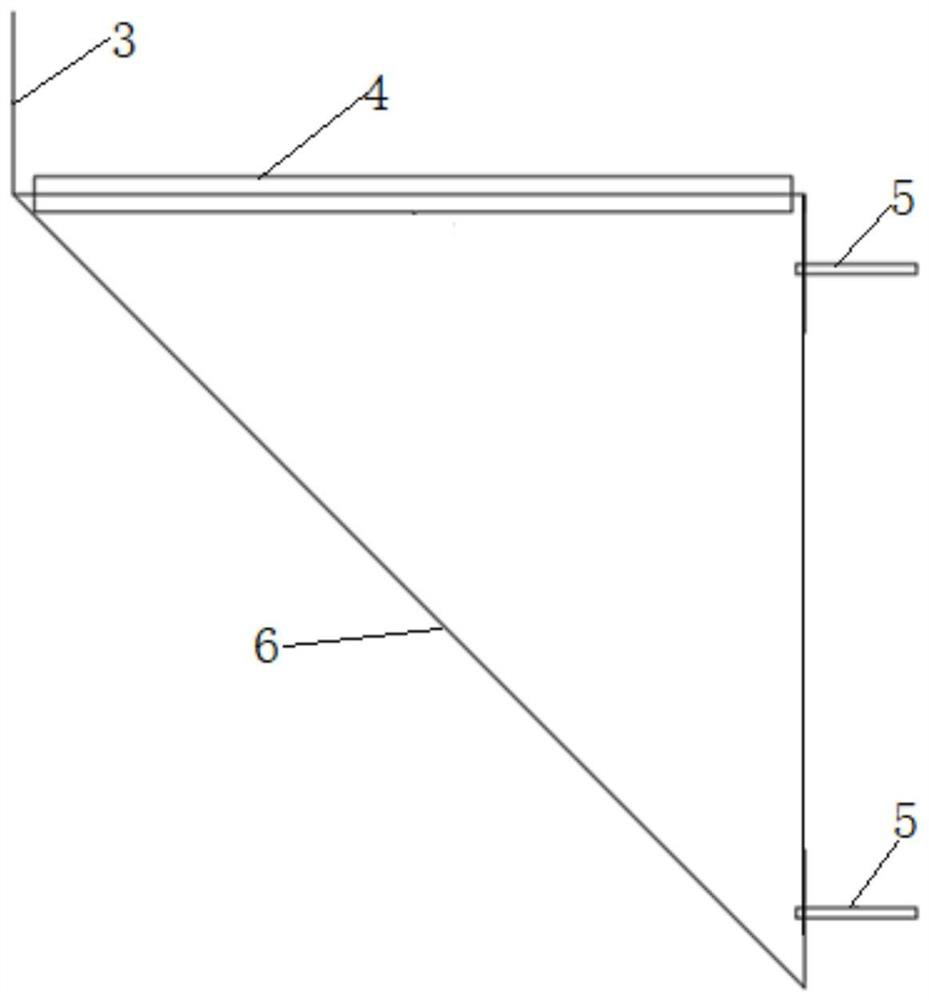

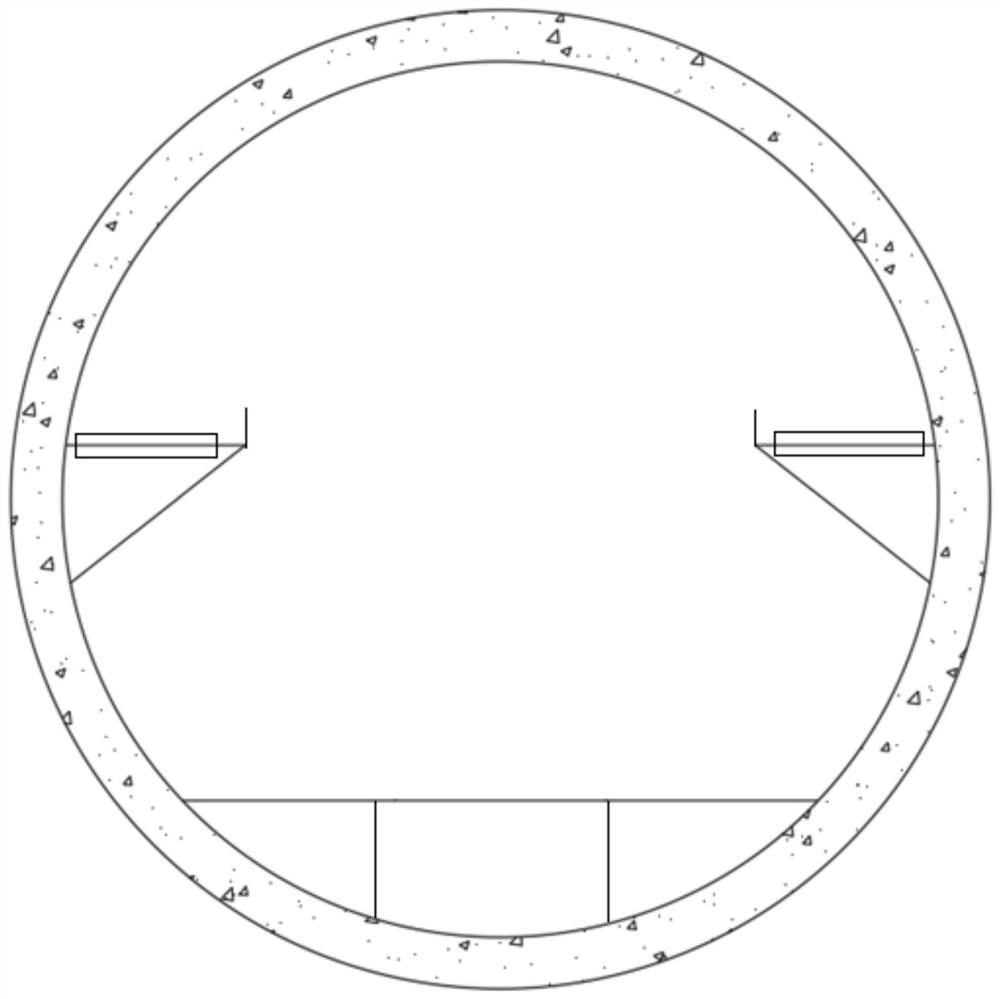

[0026] S1, such as figure 1 As shown, divide the concrete pad into several units and make prefabricated blocks 2, such as image 3 with Figure 4 As shown, the supporting roller 4 is installed along the line in the jacking pipe 1, the conveyor belt 7 is installed along the supporting roller 4 and the power device of the conveyor belt is installed in the originating shaft, and the prefabricated block 2 is transported along the line from the originating shaft to the jacking pipe 1 through the conveyor belt 7 After assembling the prefabricated block 2 into a concrete cushion, remove the support roller 4 and the conveyor belt 7 and transfer them to the next jacking pipe 1 to continue the construction of the concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com