Hollow glass based on single-component solventless hot melt adhesive and processing method thereof

A hot-melt adhesive and solvent-free technology, applied in the field of hot-melt adhesives, can solve the problems of easy condensation, heavy weight, and high cost, and achieve the effects of improving barrier performance, reducing overall quality, and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

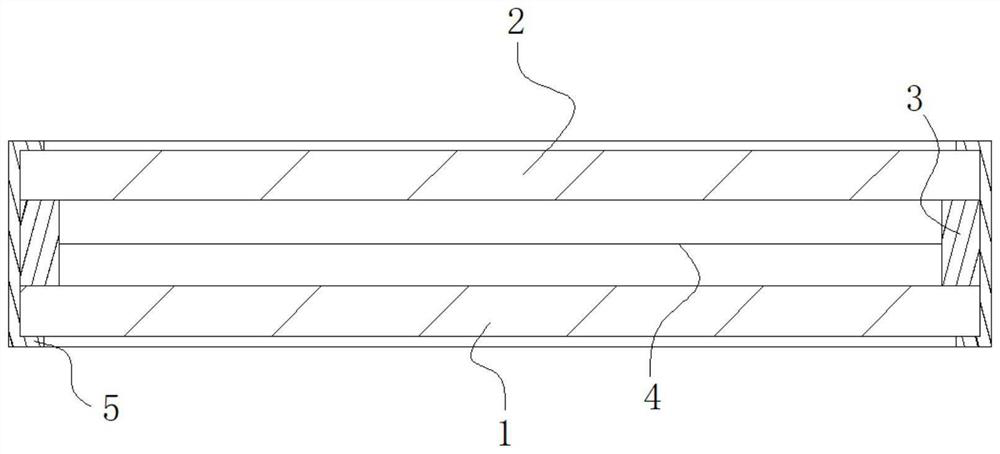

[0033] Example 1: A kind of insulating glass based on one-component solvent-free hot melt adhesive, refer to the attached figure 1 , comprising an inner glass 1, an outer glass 2, a spacer 3, a film spacer 4 and an edge-sealing metal film 5, and the spacer 3 is encapsulated on the periphery of the inner glass 1 and the outer glass 2 by hot-melt adhesive In between, the surroundings of the film spacer 4 are respectively bonded to the inner side of the corresponding spacer 3 by hot melt adhesive, and the film spacer separates the space between the inner glass 1 and the outer glass 2, and the sealing The edge metal film 5 is bonded to the spacer 3 by hot melt adhesive and covers the inner glass 1 and the outer glass 2 on both sides;

[0034] Wherein, the film material interlayer 4 is a light-transmitting film material, which has good weather resistance, high light transmittance, and functions such as filtering ultraviolet rays; the film material interlayer 4 is arranged with seve...

Embodiment 2

[0048] Embodiment 2: A kind of insulating glass based on one-component solvent-free hot melt adhesive, refer to the attached figure 1 , comprising an inner glass 1, an outer glass 2, a spacer 3, a film spacer 4 and an edge-sealing metal film 5, and the spacer 3 is encapsulated on the periphery of the inner glass 1 and the outer glass 2 by hot-melt adhesive In between, the surroundings of the film spacer 4 are respectively bonded to the inner side of the corresponding spacer 3 by hot melt adhesive, and the film spacer separates the space between the inner glass 1 and the outer glass 2, and the sealing The edge metal film 5 is bonded to the spacer 3 by hot melt adhesive and covers the inner glass 1 and the outer glass 2 on both sides;

[0049] Wherein, the film material interlayer 4 is a light-transmitting film material; the film material interlayer 4 is arranged with several layers along the direction perpendicular to the inner glass; between the inner glass 1 and the outer gla...

Embodiment 3

[0063] Embodiment 3: a kind of processing method of insulating glass based on one-component solvent-free hot-melt adhesive, is characterized in that, comprises the following steps:

[0064] S1: Before assembling insulating glass in a dry environment, use an adhesion promoter (Lian Technology Primer Coating Agent) to coat the inner glass 1, outer glass 2, spacer strip 3, and edge-banding metal film 5 bonding surface;

[0065] S2: Apply hot melt adhesive heated to 110-160°C on one side of the spacer 3, and press it to the edge of the inner glass 1;

[0066] S3: After the spacer 3 and the inner glass 1 are firmly bonded, apply hot melt adhesive on the film interlayer 4, and press it onto the inner wall of the corresponding spacer 3, select the number of film interlayer 4 as required, and laid out sequentially;

[0067] S4: Apply hot melt adhesive heated to 110-160°C on the other side of the spacer 3, and press and fix the outer glass 2 onto the spacer 3 to align with the inner g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com