A low-cost photothermal material based on solar interface evaporation and its preparation method

A low-cost, solar-powered technology, applied in chemical instruments and methods, general water supply conservation, organic chemistry, etc., can solve problems such as complex preparation process, limited water supply, and decreased steam conversion rate, and achieve simple preparation method, high-efficiency evaporation rate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

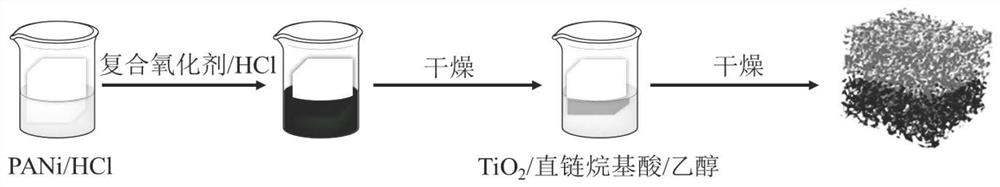

[0027] A preparation method of a low-cost photothermal material (the schematic diagram of the preparation process is shown in figure 1 shown), including the following steps:

[0028] 1) Prepare the solution:

[0029] Take 1 mL of aniline and add it to 20 mL of 1 mol / L hydrochloric acid aqueous solution and sonicate for 20 min. After the sonication is finished, prepare an aniline solution for future use. Take 0.365g of ammonium persulfate (APS, used as an oxidizing agent) and add it into 10mL of 1mol / L hydrochloric acid aqueous solution and sonicate for 20min to prepare an oxidizing agent solution for later use.

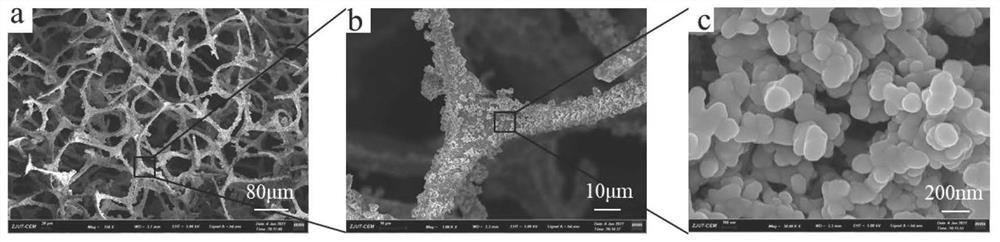

[0030] 2) Growing polyaniline: Prepare melamine foam, which has a cuboid structure with a length of 3 cm, a width of 3 cm, and a height of 2 cm. Add the melamine foam to the aniline solution prepared in step 1), and after soaking for 30 minutes at room temperature, the aniline solution completely enters the lower part of the melamine foam, and the height of the anil...

Embodiment 2

[0051] The preparation method of the low-cost photothermal material of Example 2 is repeated in Example 1, the difference is only that "in the step 1) of Example 2, in preparing the oxidant solution, 0.365g of ammonium persulfate (APS) is replaced with a total mass of 0.365 g of APS with FeCl 3 Mixture, APS and FeCl 3 The mass ratio is 1:1", and other operations are the same as in Example 1, and finally a low-cost photothermal material is obtained.

Embodiment 3

[0053] The preparation method of the low-cost photothermal material of Example 3 is repeated in Example 1, the difference is only that in "step 1) of Example 3, in preparing the oxidizing agent solution, 0.365g of ammonium persulfate (APS) is replaced with a total mass of 0.365 g of APS with FeCl 3 Mixture, APS and FeCl 3 The mass ratio is 1:2", and other operations are the same as in Example 1, and finally a low-cost photothermal material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Evaporation rate | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com