Eucommia ulmoides leaf pretreatment method for extracting pinoresinol diglucoside from eucommia ulmoides leaves

A technology of pinoresinol diglucoside and eucommia leaves, which is applied in the field of pretreatment before plant extraction, and can solve the problems of drug efficacy loss, easy loss of leaf active ingredients, leaf deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] In this embodiment, the specific processing scheme is mainly introduced.

[0079] First, the pretreatment of Eucommia leaves:

[0080] (1) Eucommia leaves were collected from the courtyard of Xi'an Lantai Pharmaceutical Co., Ltd. in Shaanxi Province. The picking month was October. Fresh leaves with a clean surface, no wormholes, and no dryness were selected, rinsed with tap water, and stored in a freezer.

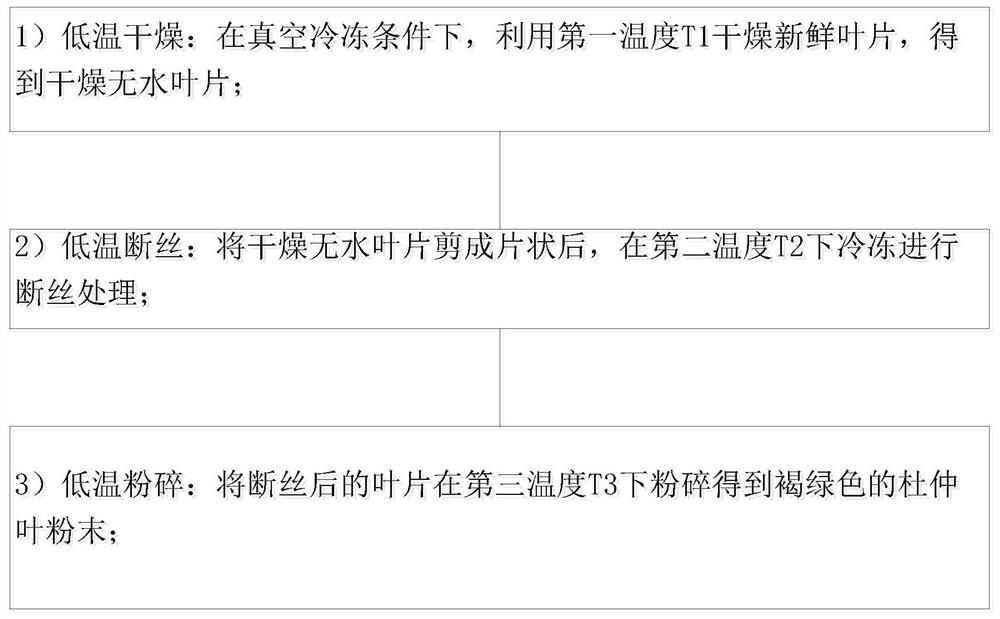

[0081] (2) Using a small vacuum freeze dryer (LGJ-18NS), dry the washed leaves at -80°C under vacuum conditions for 48 hours to obtain dry, anhydrous leaves.

[0082] (3) Cut the leaves into pieces (the particle size is about 2-3cm 2) , Freeze at -15°C for 1 h for wire breakage.

[0083] (4) Put the broken leaves into a vibrating cell-grade ultrafine pulverizer with temperature control, and pulverize at 4°C for 1 hour to obtain a brown-green powder, which is stored in a brown glass bottle away from light.

[0084] Secondly, the extraction of Eucommia leaves:

[0...

Embodiment 2

[0110] The Eucommia leaf powder in Example 1 was used as a sample, and the extraction and identification were continued.

[0111] Extraction of active ingredients from Eucommia leaves:

[0112] (1) Weigh 10.0036g of eucommia leaf powder, add ethanol solution with a mass fraction of 65%, the ratio of solid to liquid is 15mL:1g, adjust the pH of the extract to 7.4, place it in an ultrasonic cleaner, set the temperature to 70°C, and extract The time is 1.5h, and the dregs are removed by suction filtration while it is hot.

[0113] (2) Add an ethanol solution with a mass fraction of 65% to the dregs, the ratio of solid to liquid is 15mL:1g, adjust the pH of the extract to 9.1, place it in an ultrasonic cleaner, set the temperature to 70°C, and extract for 1.0h , Remove the dregs by suction filtration while hot.

[0114] (3) The two filtrates were combined, concentrated under reduced pressure to 30 mL, centrifuged for 10 min at a centrifugation speed of 8000 r / min, and the supern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com