Low-density high-strength damage-resistant aluminum-lithium alloy hot-rolled plate and preparation method thereof

An aluminum-lithium alloy, low-density technology, applied in the field of low-density, high-strength, damage-resistant aluminum-lithium alloy hot-rolled sheets and its preparation, can solve the problems of low yield strength, low density, high density, etc., and achieve safe process operation and low cost , The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

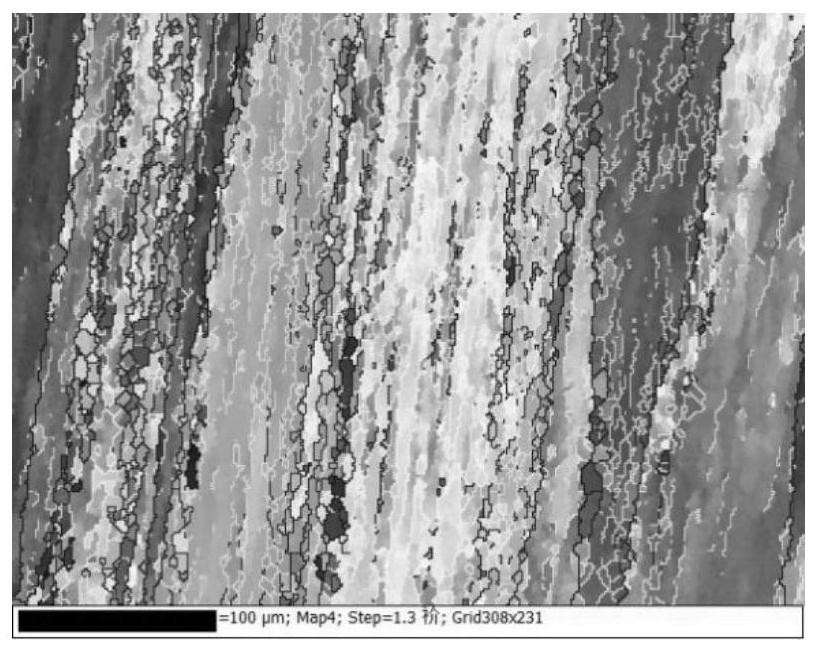

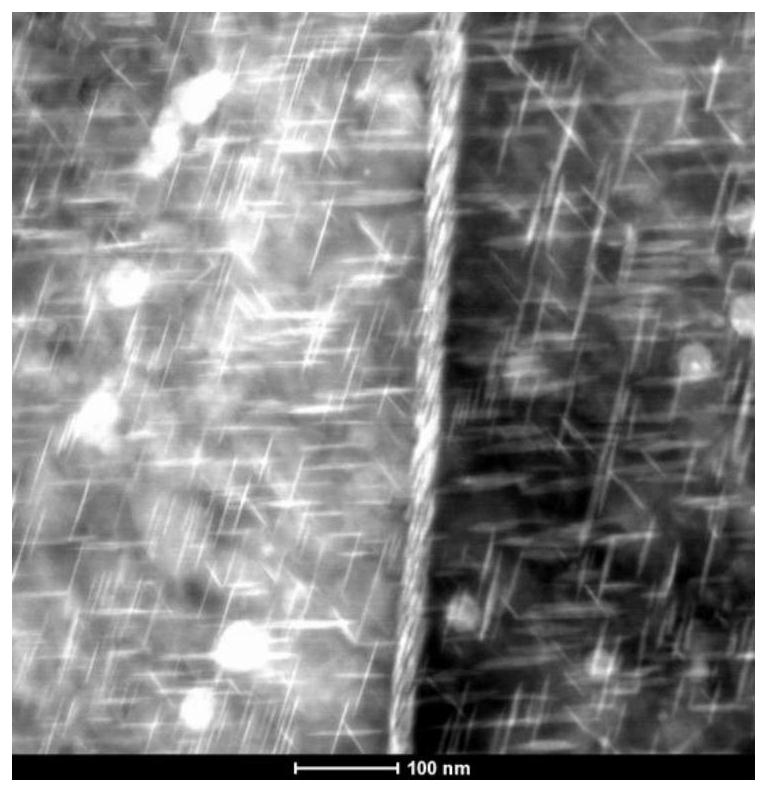

Image

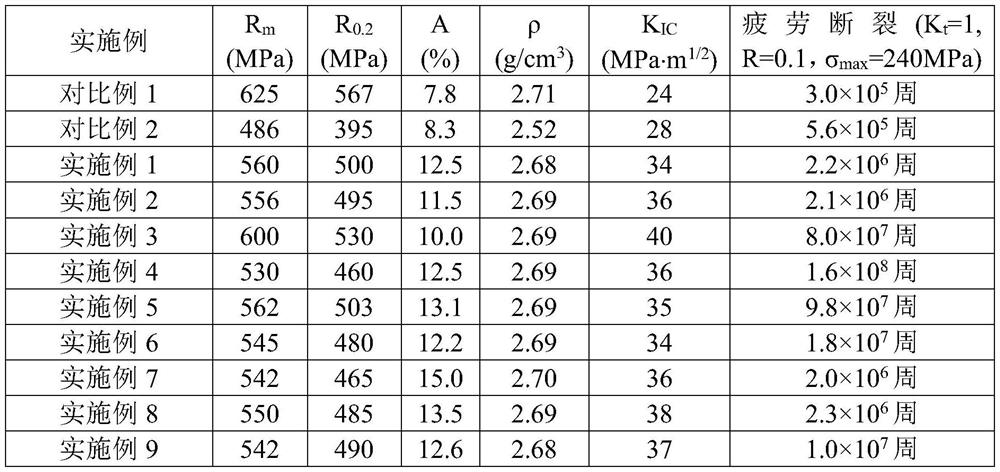

Examples

Embodiment 1

[0036] A low-density, high-strength, damage-resistant aluminum-lithium alloy hot-rolled plate, in terms of mass percentage, the final chemical composition of the alloy consists of the following components: Cu3.6%, Li1.1%, Mg0.5%, Ag0.3% , Zn0.26%, Zr0.1%, Mn0.3%, Fe0.05%, Si0.05%, the balance is Al, wherein Fe and Si elements are brought by raw materials and operating tools when preparing alloys, as Unavoidable impurity elements.

[0037] The preparation method of the above-mentioned lithium alloy hot-rolled plate comprises the following steps:

[0038] 1) Smelting: According to the designed aluminum-lithium alloy composition distribution ratio, the raw materials are added in the form of pure aluminum, pure lithium, pure magnesium, pure silver, pure zinc, Al-10Mn, Al-4Zr alloy, Al-50Cu alloy, in the vacuum Smelting in a smelting furnace, followed by casting to obtain ingots.

[0039] 2) Three-stage annealing: first raise the temperature of the cast ingot to 300°C, hold for 8...

Embodiment 2

[0045] A low-density, high-strength, damage-resistant aluminum-lithium alloy hot-rolled plate, the final chemical composition of the alloy consists of the following components in terms of mass percentage: Cu3.9%, Li1.1%, Mg0.76%, Ag0.3% , Zn0.34%, Zr0.1%, Mn0.27%, Fe0.04%, Si0.05%, the balance is Al, wherein Fe and Si elements are brought by raw materials and operating tools when preparing alloys, as Unavoidable impurity elements.

[0046] The preparation method of the above-mentioned lithium alloy hot-rolled plate comprises the following steps:

[0047] 1) Smelting: According to the designed aluminum-lithium alloy composition distribution ratio, the raw materials are added in the form of pure aluminum, pure lithium, pure magnesium, pure silver, pure zinc, Al-10Mn, Al-4Zr alloy, Al-50Cu alloy, in the vacuum Smelting in a smelting furnace, followed by casting to obtain ingots.

[0048] 2) Three-stage annealing: first raise the temperature of the cast ingot to 350°C, hold for ...

Embodiment 3

[0054] A low-density, high-strength, damage-resistant aluminum-lithium alloy hot-rolled plate, the final chemical composition of the alloy consists of the following components in terms of mass percentage: Cu3.8%, Li1.0%, Mg0.9%, Ag0.25% , Zn0.25%, Zr0.15%, Mn0.2%, Fe0.05%, Si0.04%, the balance is Al, wherein Fe and Si elements are brought by raw materials and operating tools when preparing alloys, as Unavoidable impurity elements.

[0055] The preparation method of the above-mentioned lithium alloy hot-rolled plate comprises the following steps:

[0056] 1) Smelting: According to the designed aluminum-lithium alloy composition distribution ratio, the raw materials are added in the form of pure aluminum, pure lithium, pure magnesium, pure silver, pure zinc, Al-10Mn, Al-4Zr alloy, Al-50Cu alloy, in the vacuum Smelting in a smelting furnace, followed by casting to obtain ingots.

[0057] 2) Three-stage annealing: first raise the temperature of the ingot to 380°C, hold for 3 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com