Fracturing preposed authigenic acid system and fracture reduction method thereof

A self-generating acid and system technology, applied in chemical instruments and methods, mining fluids, earth drilling and production, etc., can solve problems such as hydraulic fracturing failure, abnormal reservoir fracture pressure, pipe string corrosion, etc., and achieve uniform reduction of fracture pressure, Easy transportation, little corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

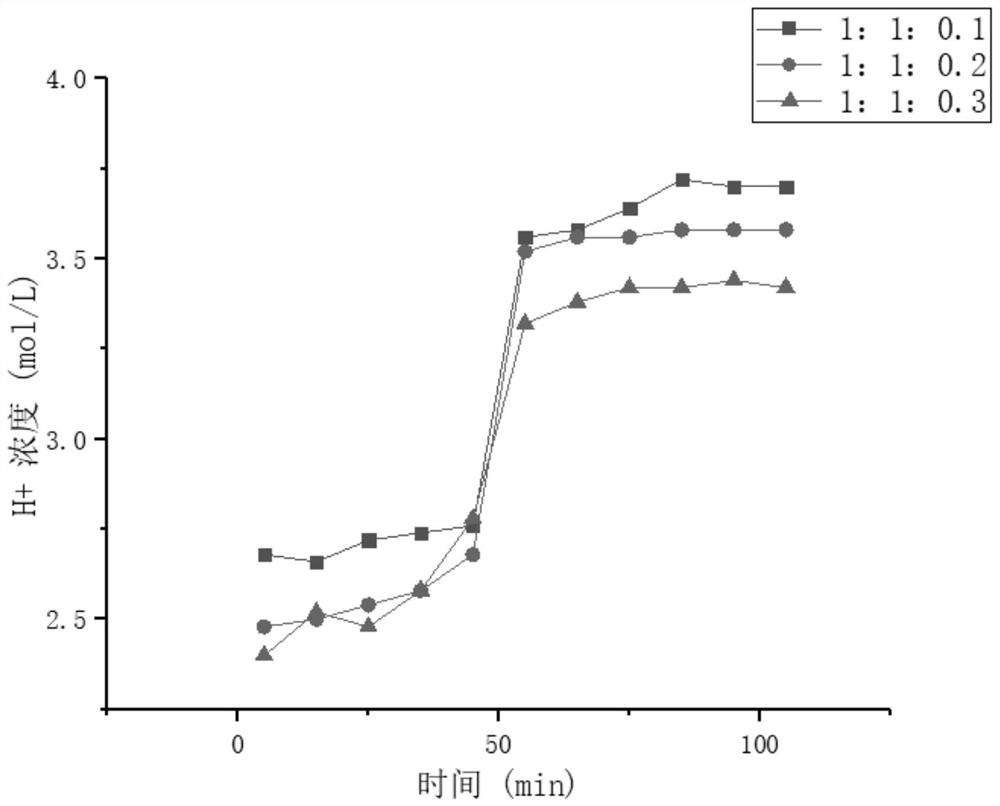

[0031] In 70ml of water, add 30g of paraformaldehyde (polymerization degree n is 10 to 100) to form autogenic acid mother liquor A; in 70ml of water, add 30g of ammonium chloride to form authigenic acid mother liquor B. In 70ml of water, add 30g of ammonium fluoride to form autogenic acid mother solution C. After the three are mixed in different volume ratios, they are quickly placed in a water bath at 50°C, and the acid generation data after the three are mixed are measured, as shown in the figure. from figure 1 It can be seen that the acid generation effect is the best when the three are mixed at a volume ratio of 1:1:0.1, and the hydrogen ion concentration reaches 3.70mol / L.

Embodiment 2

[0033] (1) In 70ml of water, add 30g of paraformaldehyde (polymerization degree n is 10 to 100) to form autogenic acid mother solution A; in 70ml of water, add 30g of ammonium chloride to form autogenic acid mother solution B. In 70ml of water, add 30g of ammonium fluoride to form autogenic acid mother solution C. Prepare a mixed solution of autogenous acids A, B, and C at a volume ratio of 1:1:0.1 to form a mixed solution 1 with a volume of 50ml.

[0034] (2) Add 0.6% sodium polyoxyethylene lauryl ether sulfate to the mixed solution in (1) to form a mixed solution 2 with a volume of 50 ml.

[0035] (3) Configure a mixed solution of autogenous acid mother liquor B with a mass concentration of 16% and gas initiator sodium nitrite with a mass concentration of 21% to form a mixed solution 3 with a volume of 50ml.

[0036] (4) Mix the mixed solution 2 and the mixed solution 3 together again to form the mixed solution system 4 with a volume of 100ml, and the container used is a 2L...

Embodiment 3

[0039] (1) In 70ml of water, add 30g of paraformaldehyde (polymerization degree n is 10 to 100) to form autogenous acid mother liquor A; in 70ml of water, add 30g of ammonium chloride to form autogenous acid mother liquor B. In 70ml of water, add 30g of ammonium fluoride to form autogenic acid mother solution C. Prepare a mixed solution of autogenous acids A, B, and C at a volume ratio of 1:1:0.1 to form a mixed solution 1 with a volume of 50ml.

[0040] (2) Add 0.6% sodium polyoxyethylene lauryl ether sulfate to the mixed solution in (1) to form a mixed solution 2 with a volume of 50 ml.

[0041] (3) Configure a mixed solution of autogenous acid mother liquor B with a mass concentration of 16% and gas initiator ammonium persulfate with a mass concentration of 21% to form a mixed solution 3 with a volume of 50ml.

[0042] (4) Mix the mixed solution 2 and the mixed solution 3 together again to form the mixed solution system 4 with a volume of 100ml, and the container used is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com