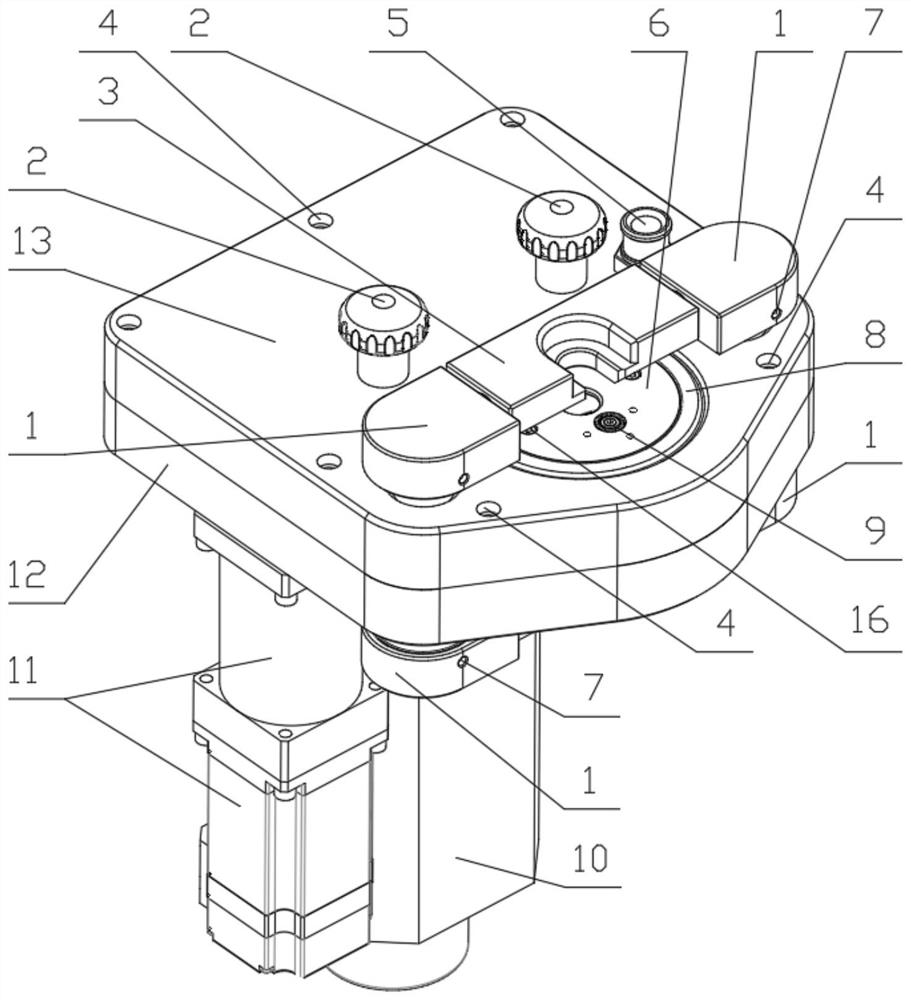

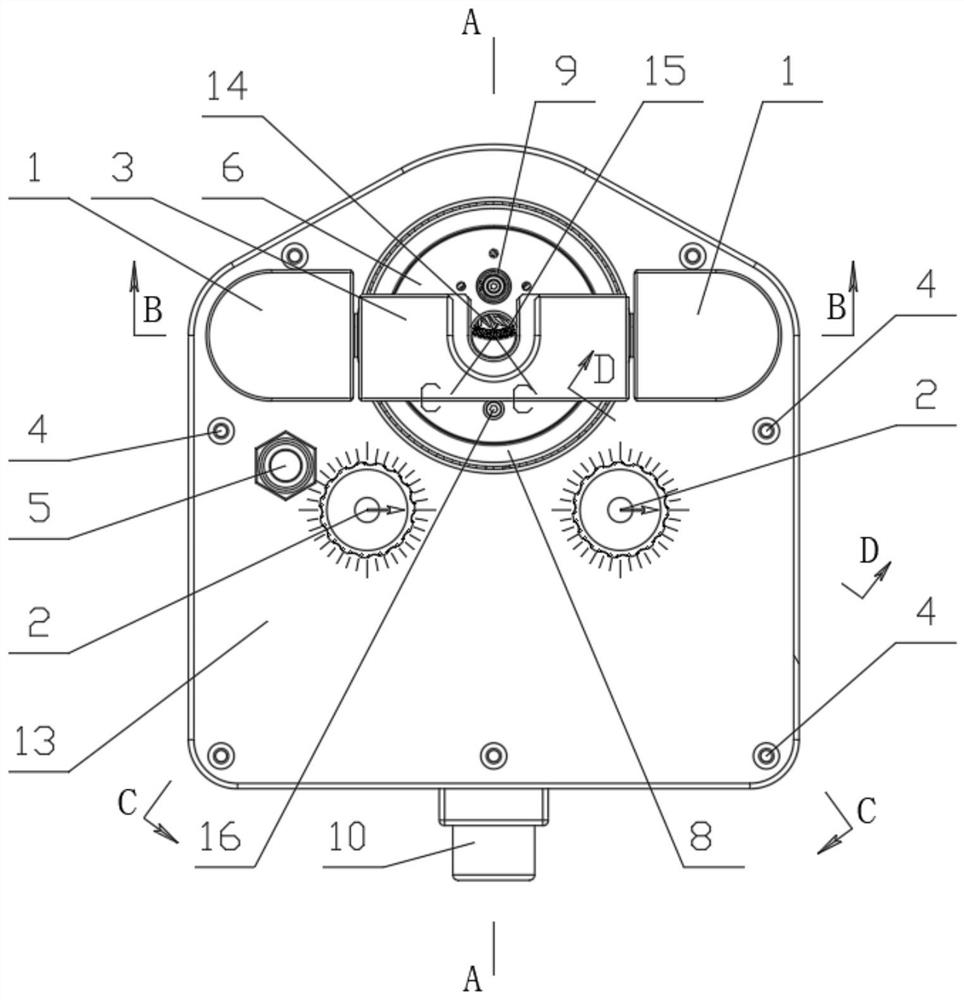

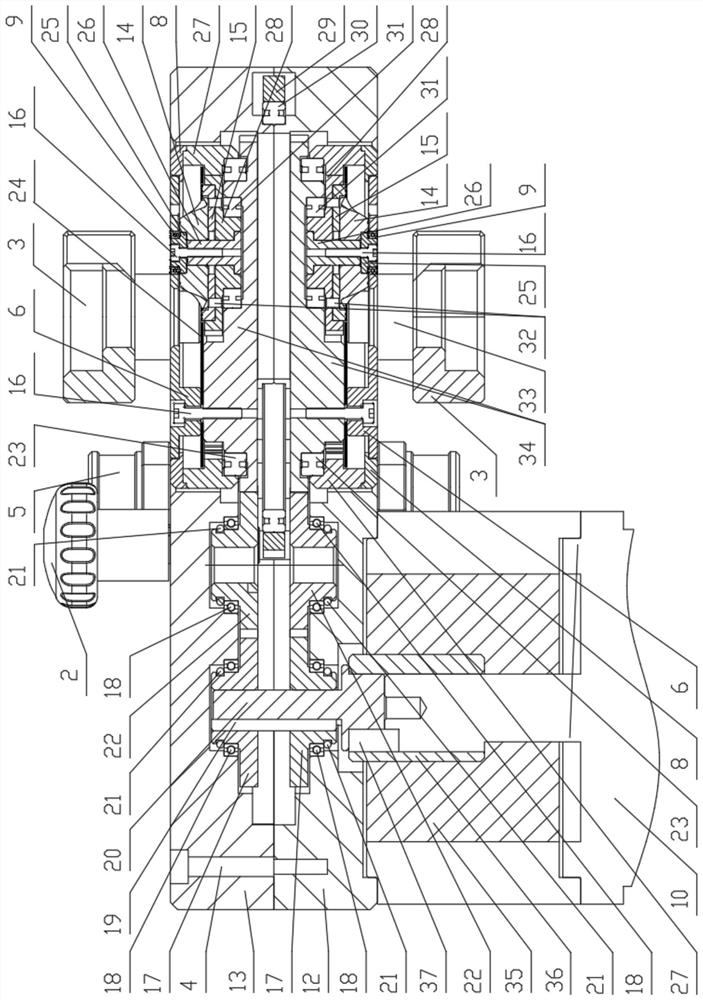

Spherical-cage-free symmetrical type spot-welding electrode automatic grinding device

A spot welding electrode, symmetrical technology, applied in the direction of electrode characteristics, electrode maintenance, etc., can solve the problems of lack of grinding angle compensation ability, dull cutting edge, prolonged time, etc., to reduce the energy consumption of spot welding process, The effect of reducing electrode consumption and reducing the amount of unnecessary grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The invention relates to special equipment for automatic grinding of welding electrodes on both sides of machine arms of various automatic welding tongs and fixed spot welding machines in the process of resistance spot welding. The electrode automatic sharpening device of the present invention adopts the multi-blade combined cutting tool and the working mode of cutting tool revolution + rotation in the electrode grinding process to cut and grind the electrode to be ground; during the cutting and grinding process of the electrode, the cutting edge of the cutting tool does not bear the pressure of the electrode , and there are no adverse working conditions such as the unfavorable working conditions that the cutting edge on one side of the cutting tool must bear the scraping of the back edge and the hard extrusion that the local cutting edge of the cutting edge passes through its axis of rotation must bear. The fixed-displacement cutting under certain conditions realizes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com