Root polishing equipment used during manufacturing of wind turbine generator blades

A technology of wind turbines and blades, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of high dust concentration, human injury, cuts, etc., to reduce operating time, reduce labor costs, and be environmentally friendly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

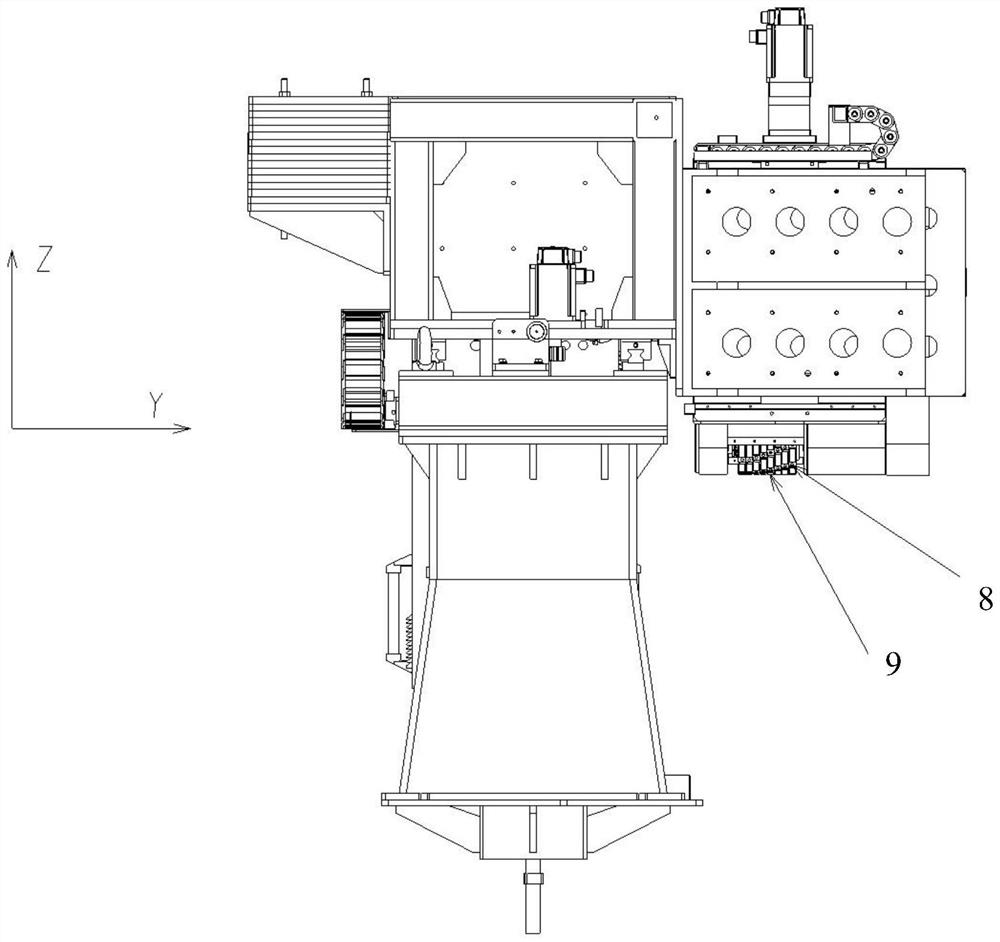

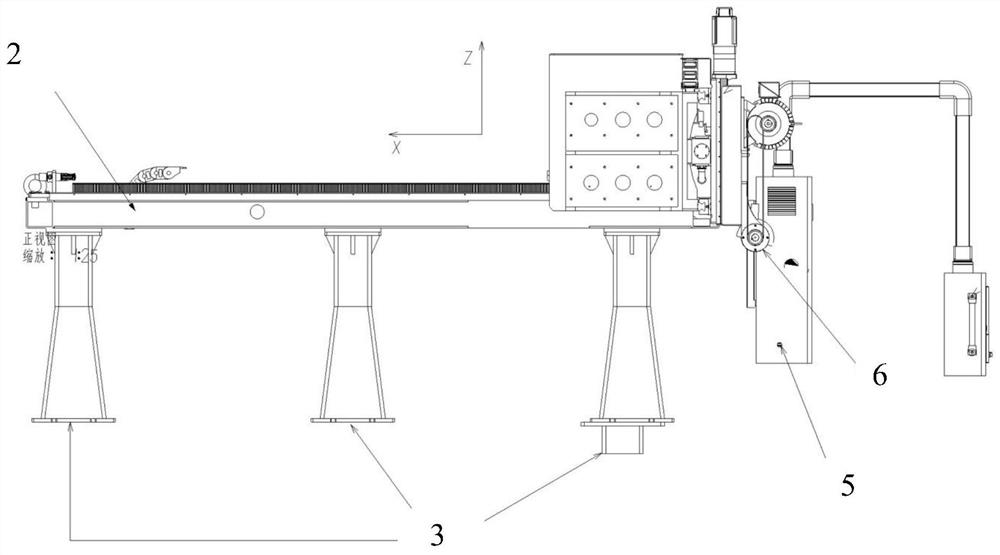

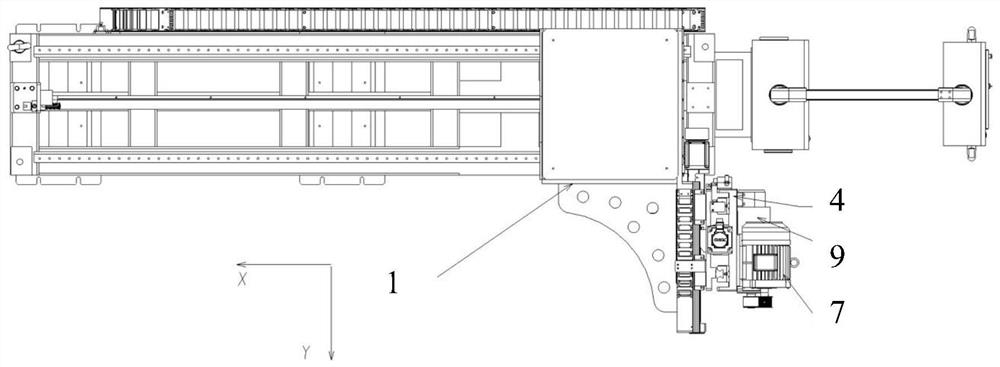

[0018] In order to better understand the purpose, structure and function of the present invention, a root grinding device for wind turbine blade manufacturing according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] Such as Figure 1 to Figure 3 As shown, it is shown as an automatic root grinding equipment for wind turbine blade production of the present invention. The automatic blade root grinding equipment of the present invention adopts automatic processing technology, replacing traditional manual grinding, and can automatically grind the blade root. into a given process size.

[0020] Further, the automatic root grinding equipment includes a positioning bracket 3 and a whole machine frame 2, and the whole machine frame 2 is supported by a plurality of positioning brackets 3 . The machine frame 2 and the positioning bracket 3 are used to meet the load requirements of the equipment during processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com