Feeding and dedusting integrated machine and using method thereof

An all-in-one machine and dust collector technology, which is applied in the field of dust removal equipment and concrete feeding of shotcrete machines, can solve the problems of poor working environment, unfavorable health of employees, uneven mixing and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

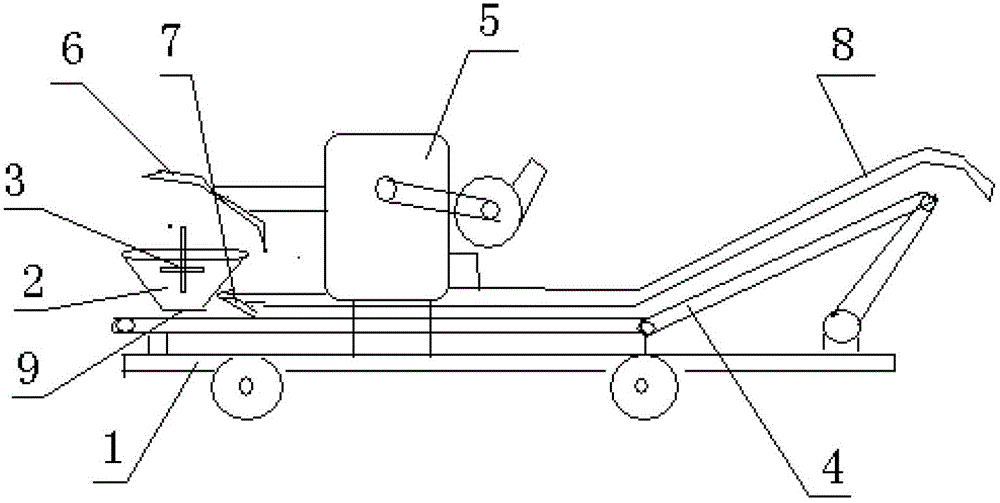

[0011] Such as figure 1 Shown, a kind of feeding, dedusting all-in-one machine, it is to be provided with mixing tank 2, conveyer belt 4 and dedusting machine 5 on rail-wheel type transport chassis 1; The bottom surface of the material trough 2 is provided with a discharge port 9, and the discharge port 9 faces the conveyor belt 4, and the conveyor belt 4 is sent to the spraying machine, and the feed port of the mixing tank 2 is provided with a first dust suction cover 6, and the discharge The port 9 is provided with a second dust collection cover 7, and the conveyor belt 4 is provided with a third dust collection cover 8, and the first dust collection cover 6, the second dust collection cover 7 and the third dust collection cover 8 are all communicated with the dust collector 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com