Auxiliary gear for internal combustion engine

A technology for internal combustion engines and gears, applied to belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problems of cost and durability, and achieve the effects of gear cost reduction, uniform deformation, and uniform material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

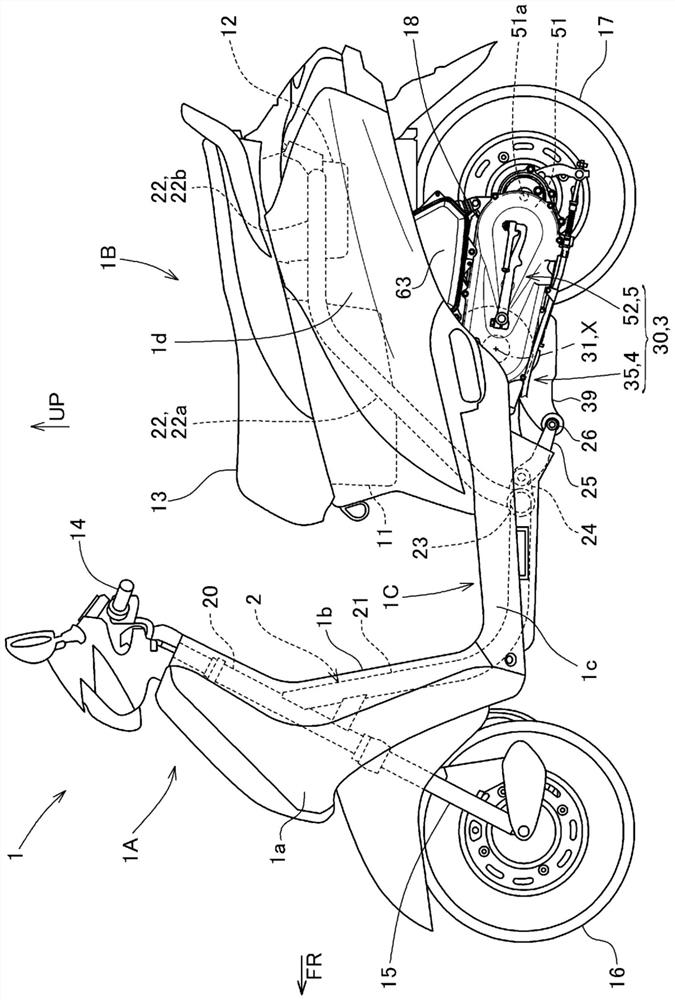

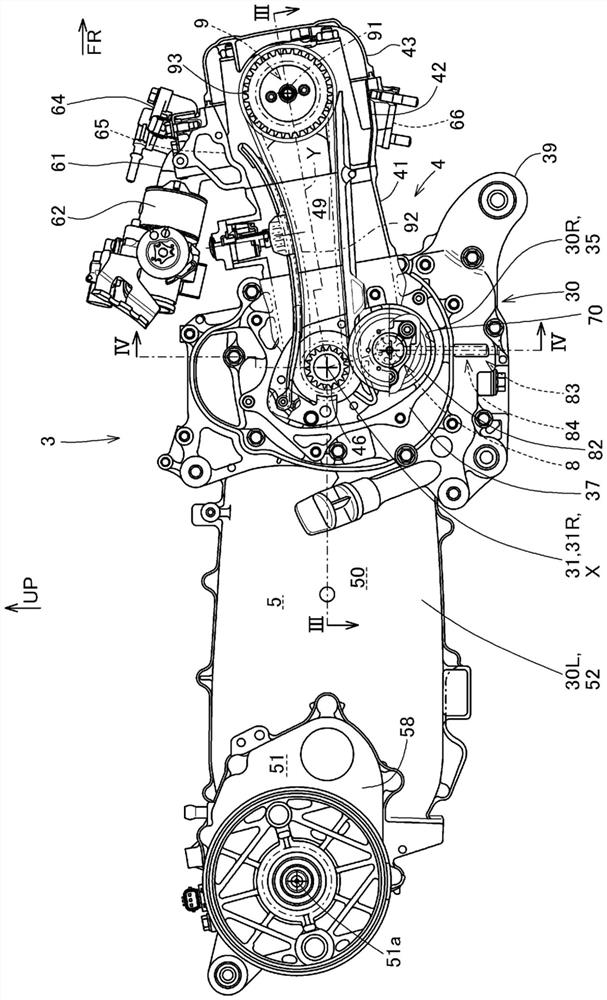

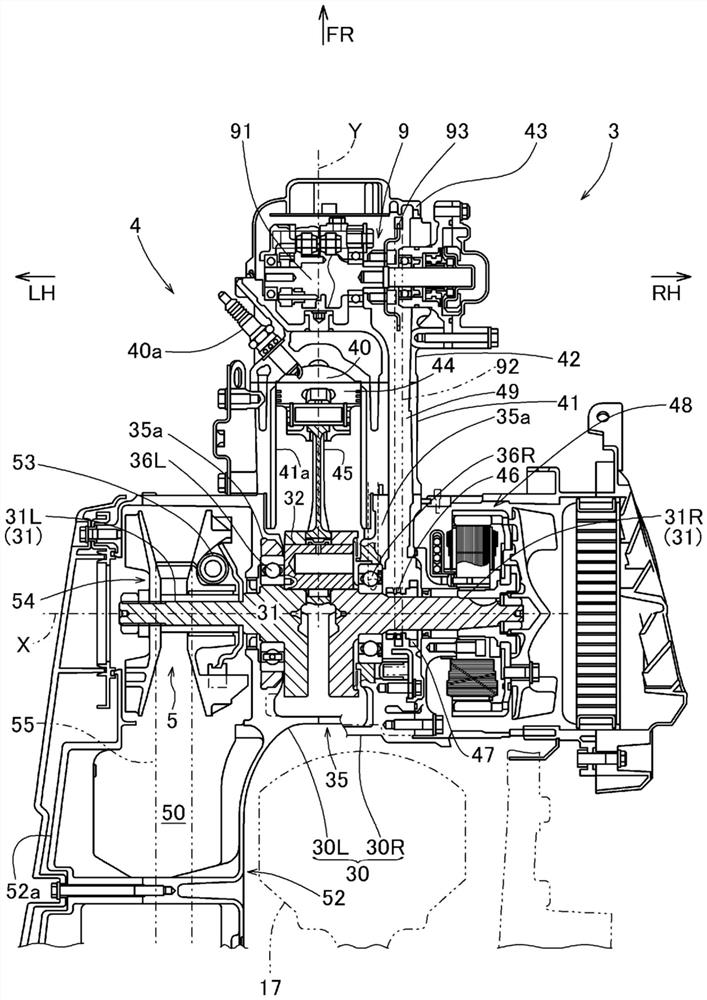

[0045] based on Figure 1 to Figure 10 , an auxiliary gear for an internal combustion engine according to an embodiment of the present invention will be described.

[0046] It should be noted that directions such as front, rear, left, right, up and down in the description of the present specification and the claims are set based on the direction of the vehicle in which the internal combustion engine including the auxiliary gear for internal combustion engines according to the present embodiment is mounted on the vehicle. In the present embodiment, the vehicle is a straddle-type vehicle, specifically, a scooter-type motorcycle (hereinafter, abbreviated as "two-wheel motorcycle").

[0047] In the figure, arrow FR indicates the front of the vehicle, LH indicates the left side of the vehicle, RH indicates the right side of the vehicle, and UP indicates the upper side of the vehicle.

[0048] Figure 1 to Figure 10 For an embodiment of the present invention, figure 1 An outline o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com